Dual-purpose collimating device with seam

A collimator and dual-purpose technology, applied in the direction of using the diaphragm/collimator, etc., can solve the problems of poor accuracy and repeatability, difficult operation, negative impact on image quality, etc., and achieve high precision and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

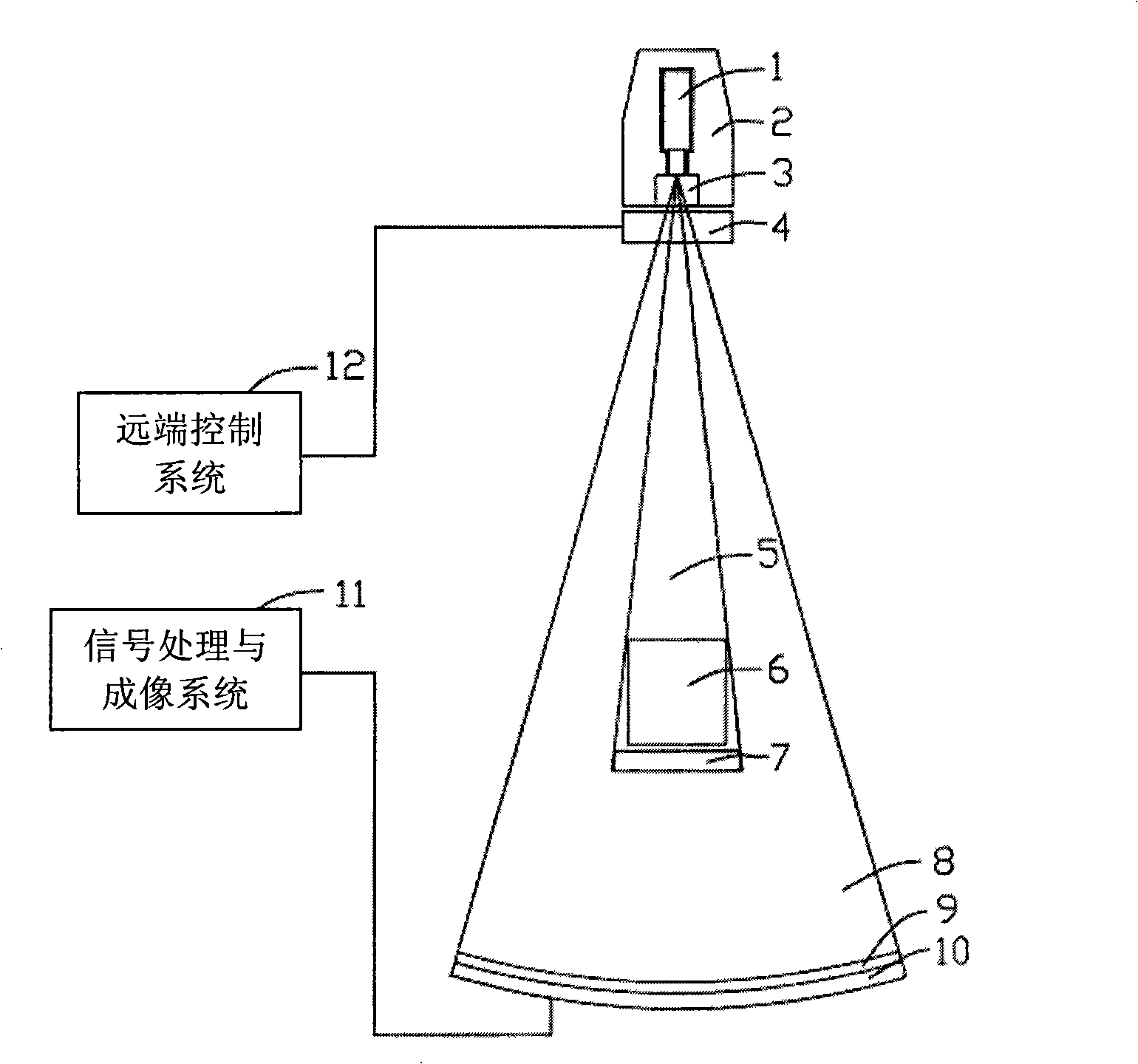

[0021] attached figure 1 It shows a specific arrangement scheme of a radiographic and CT dual-purpose non-destructive testing system applying the present invention, which mainly consists of an accelerator 1, a shielding device 2, a zeroth collimator 3, a collimator 4, a cone-shaped ray beam 5, and an inspected Object 6, X-ray photosensitive device 7, flat fan beam 8, rear collimator 9, detector 10, signal processing and imaging system 11, remote control system 12 and so on.

[0022] The accelerator is the source of X-rays, which generate a three-dimensional distribution of X-rays mainly in the forward direction and at an angle of 4π. The shielding device blocks the useless X-rays in the lateral and backward directions to eliminate the influence of stray X-rays on the quality of inspection. The null collimator confines the forward-faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com