Method for controlling an internal combustion engine

A technology of internal combustion engine and controller, applied in the direction of internal combustion piston engine, electrical control, engine control, etc., can solve the problems of clear separation effect and achieve the effect of compensating aging deviation and compensating the tolerance of new components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

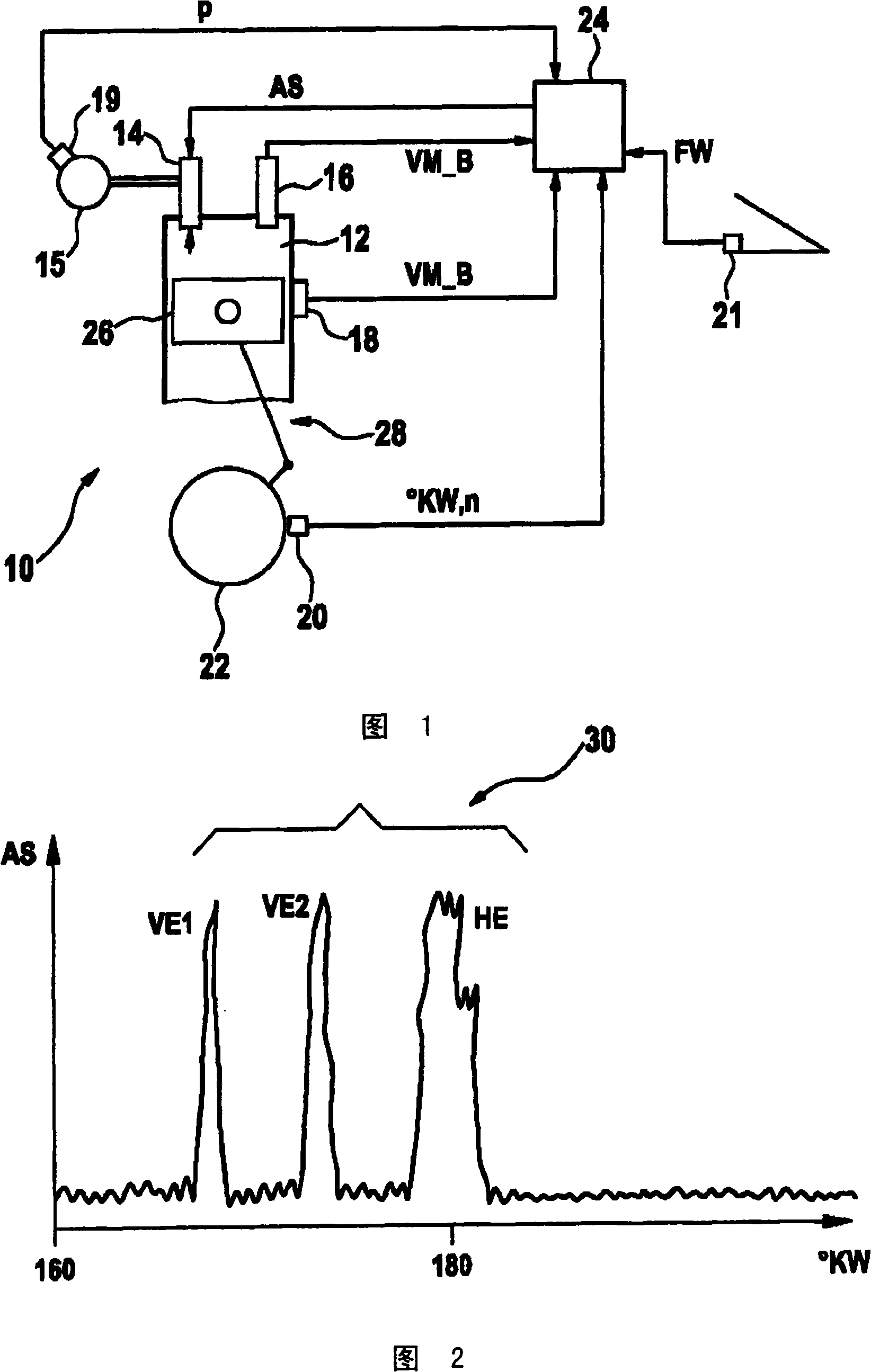

[0025] Fig. 1 shows in detail the structure with at least one combustion chamber 12, injector 14, fuel pressure accumulator 15, combustion characteristic sensor 16 and / or 18, fuel pressure sensor 19, rotating synchronously with the working cycle of internal combustion engine 10 Angle sensor 20 on component 22 , driver desire sensor 21 and control unit 24 of internal combustion engine 10 . Combustion chamber 12 is movably sealed by piston 26 . The piston is connected to the structural component 22 via a crankshaft drive 28 . Such a structural component 22 is non-rotatably connected to the crankshaft of the internal combustion engine. In another variant, however, the component can also be connected, for example, to a camshaft of internal combustion engine 10 . Of course, the actual internal combustion engine 10 also has further components, such as gas exchange valves and associated actuators for controlling the gas exchange of the combustion chamber 12 . These components are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com