Control method for cooling an industrial plant

A kind of technical equipment and equipment technology, applied in general control system, temperature control using electric mode, adaptive control, etc., can solve the problem of not considering instantaneous cooling power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

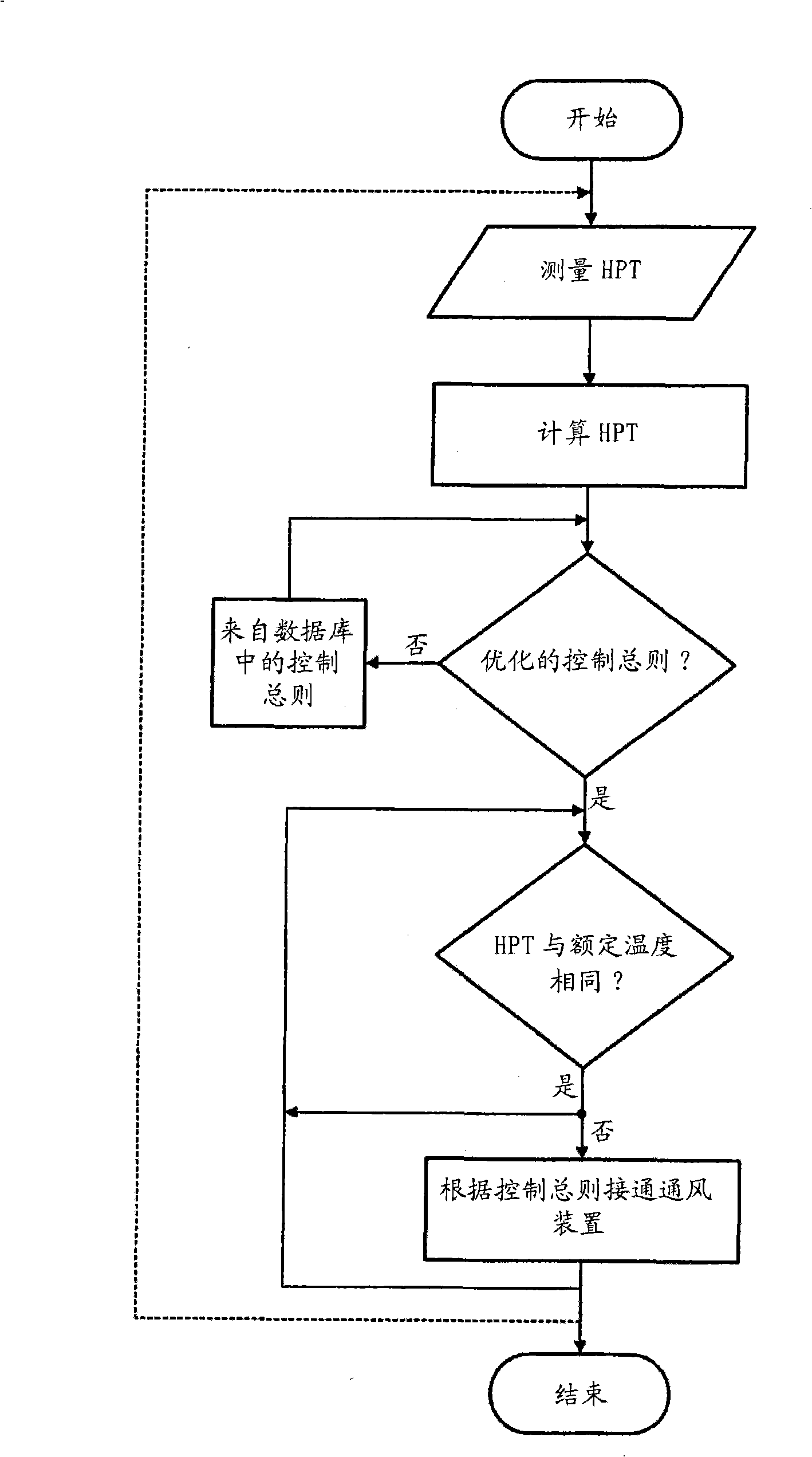

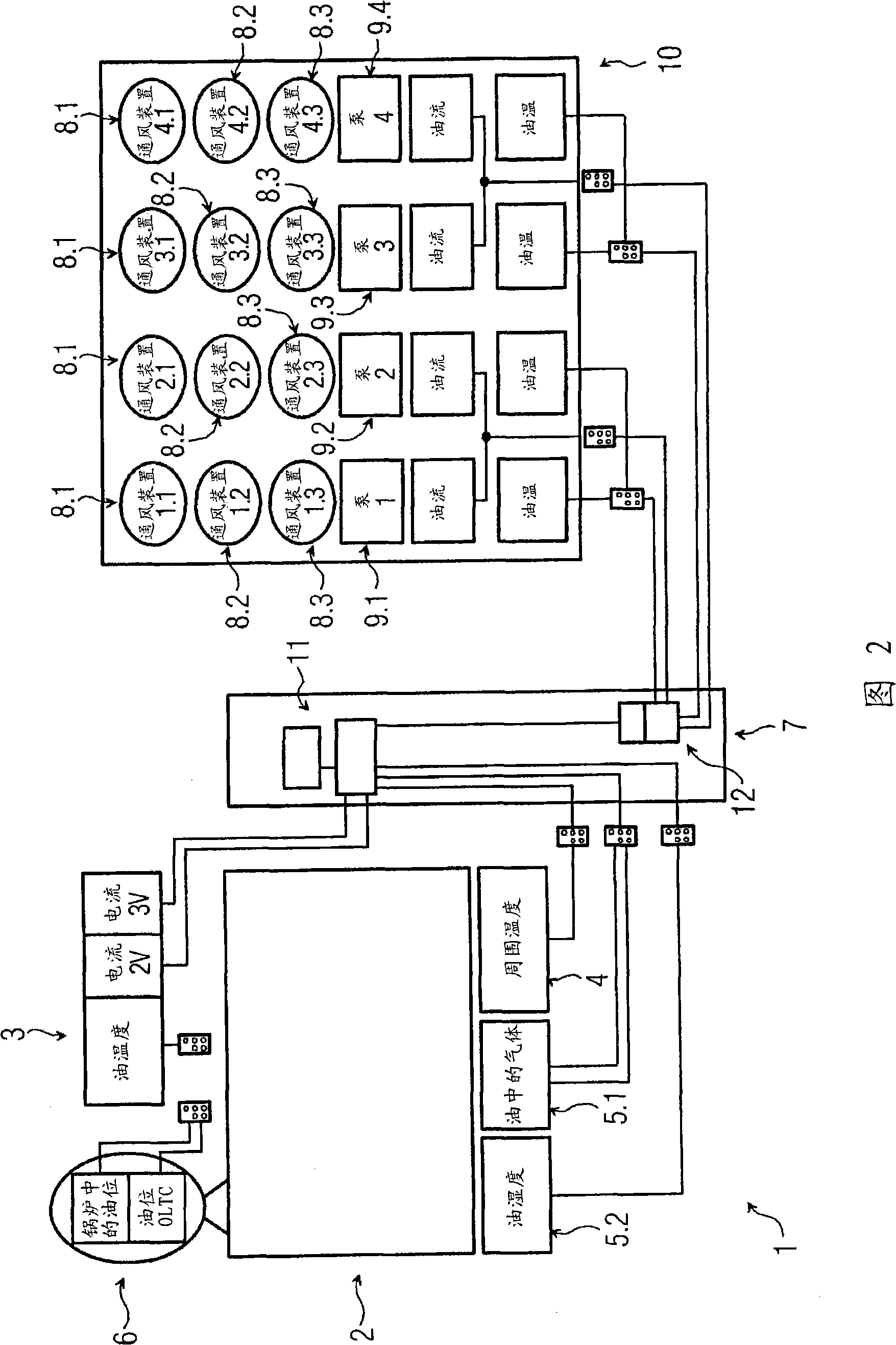

[0021] figure 1 A flow chart of the method according to the invention is shown. The current hot spot temperature (HPT) is determined from the temperature measured at the temperature sensor by means of the temperature parameters defined in the international standard IEC Standard IEC 60354. Furthermore, the ambient temperature is measured by means of the temperature sensor 4 , the state of the oil by means of the sensor 5 . 1 for the gaseous fraction in the oil and the oil moisture sensor 5 . 2 , and the oil level inside the boiler by means of the buoy 6 . The hot spot temperature (HPT) determined in this way is used in the control scheme currently used at the particular transformer 2 in order to determine the actual measured temperature of the technical installation 1 . For this purpose, an optimal control profile is selected for the current operating state, the current service life of the transformer 2 and the optimized operating state specified by the user. If an optimized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com