Pelletizing disc feeding disperser

A technology of a disperser and a pelletizing disc, which is applied in the field of ore pelletizing, can solve the problems of increasing the load of the screening system and the amount of returned material, and reducing the quality of the raw balls rolled into balls, so as to improve the quality of the rolled balls and increase the drop rate. The effect of increasing the penetration area and improving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

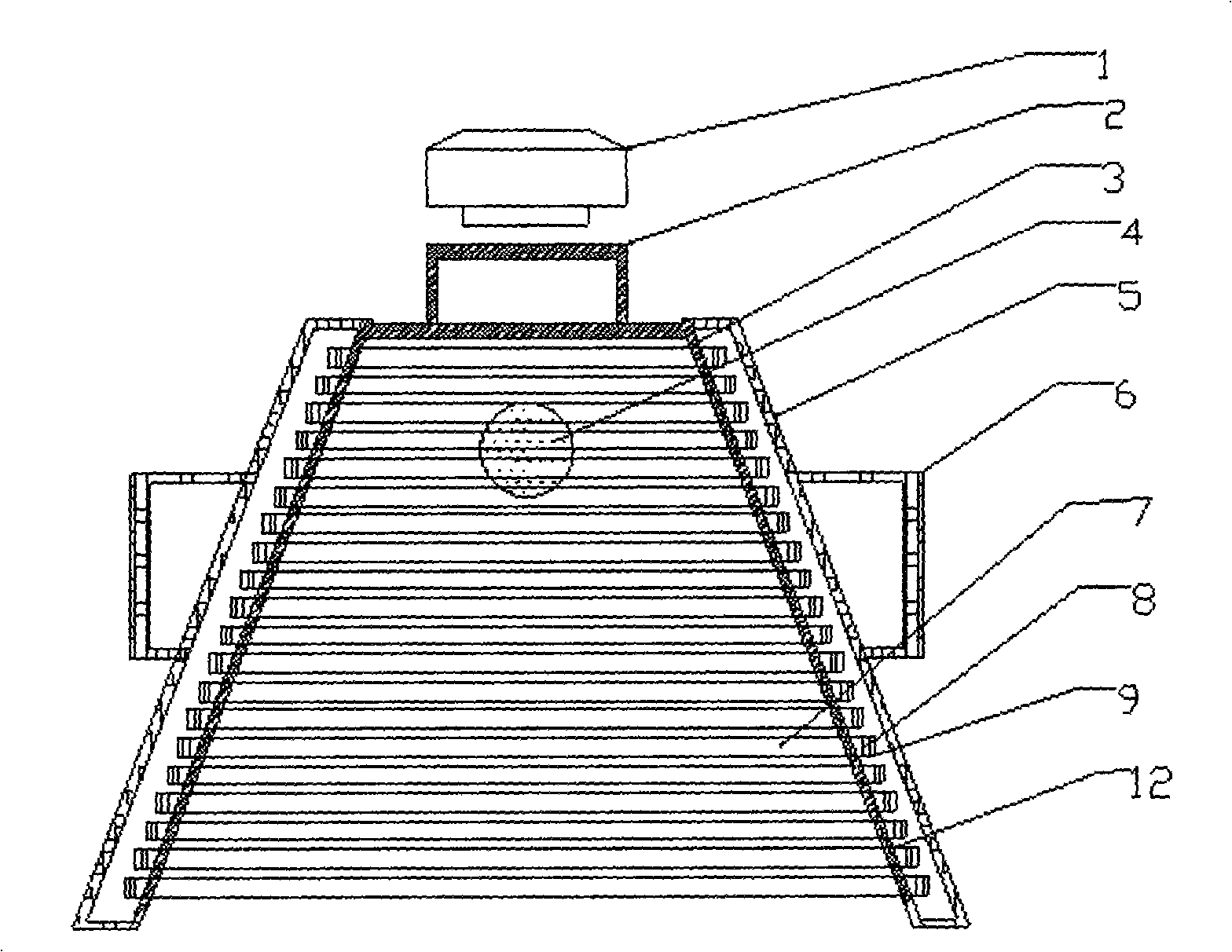

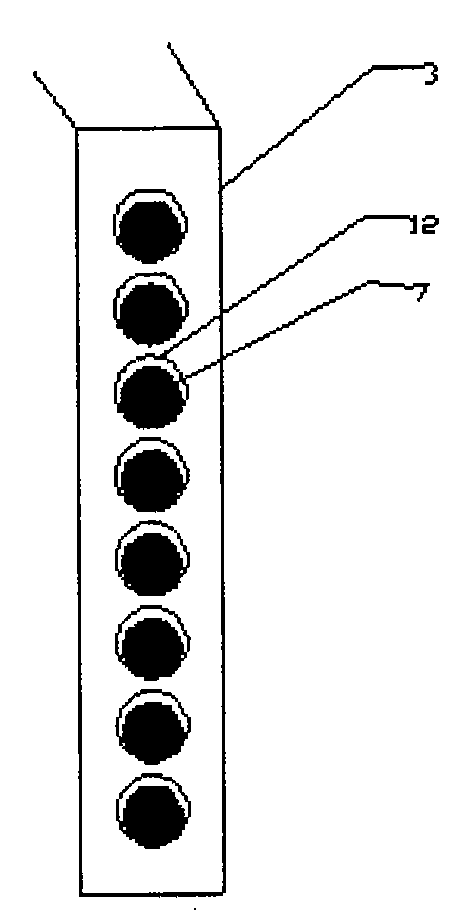

[0012] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

[0013] Such as figure 1 As shown, make a U-shaped steel support frame 3, open a plurality of round holes 12 on the two side walls of the support frame 3, put smooth and wear-resistant sticks 7 in the round holes 12, and use protective covers for the heads 9 at both ends of the stick 5 is closed, and the other side of the stick support frame 3 is welded by the impact steel plate 2 to accept the impact of the vibration motor 1. Use the fixed frame 6 to obliquely fix the disperser under the ore powder flow, and align the ore powder falling flow with the ore powder drop-in area 4 of the disperser, and the ore powder drop-in area 4 is located near the upper part of the disperser.

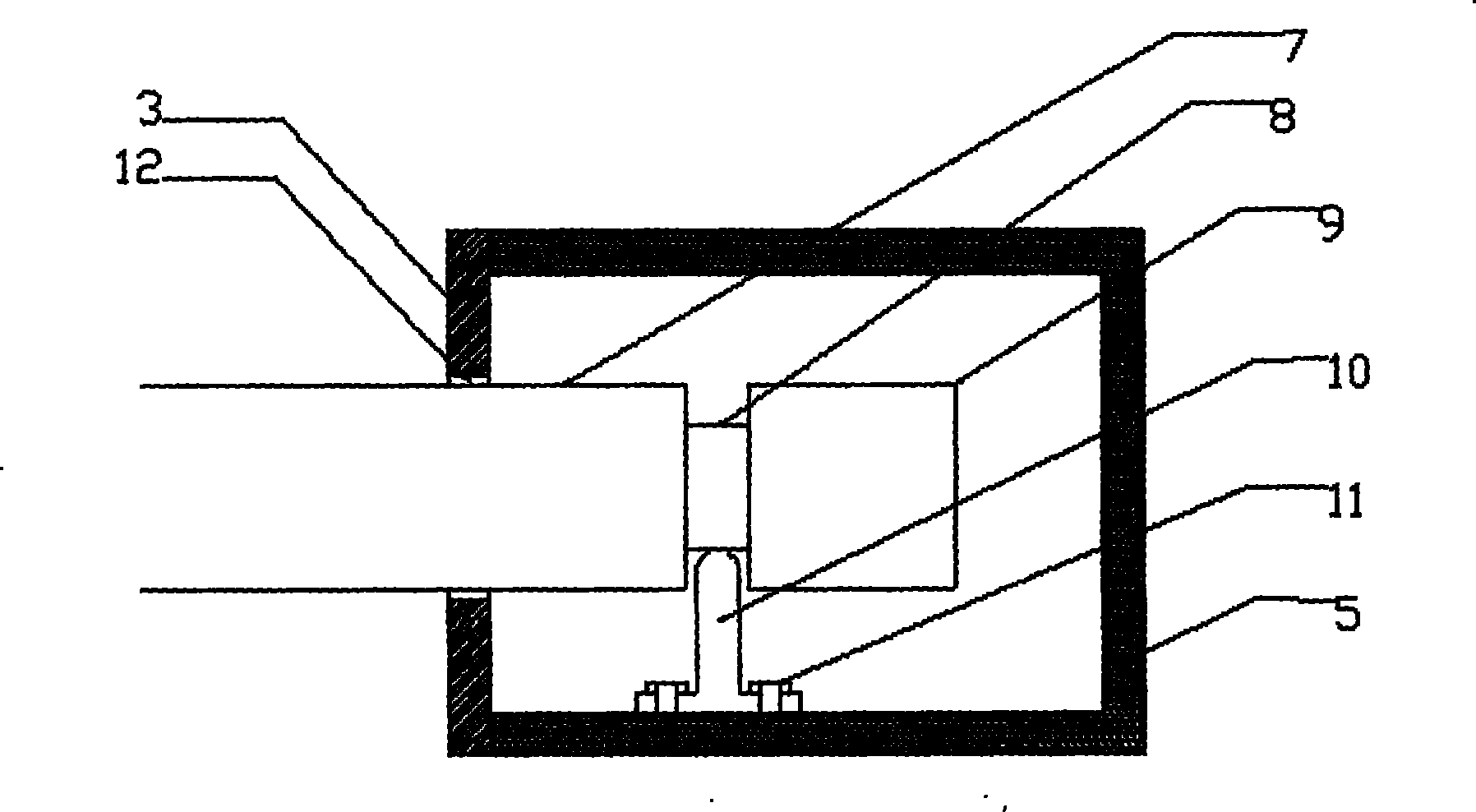

[0014] Such as figure 2 As shown, a groove 8 is opened at the head 9 positions at both ends of each stick, and at each position aligned with the groove 8, a sliding arm 10 is fixed with a bolt 11 on the protective cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com