Numerical control squaring machine

A planer and numerical control system technology, applied in the direction of planer/slotting machine, planer, large fixed members, etc., can solve the troublesome distance between the approach block and the proximity switch, the inaccurate positioning of the approach block, etc., to achieve simple control, The effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described below:

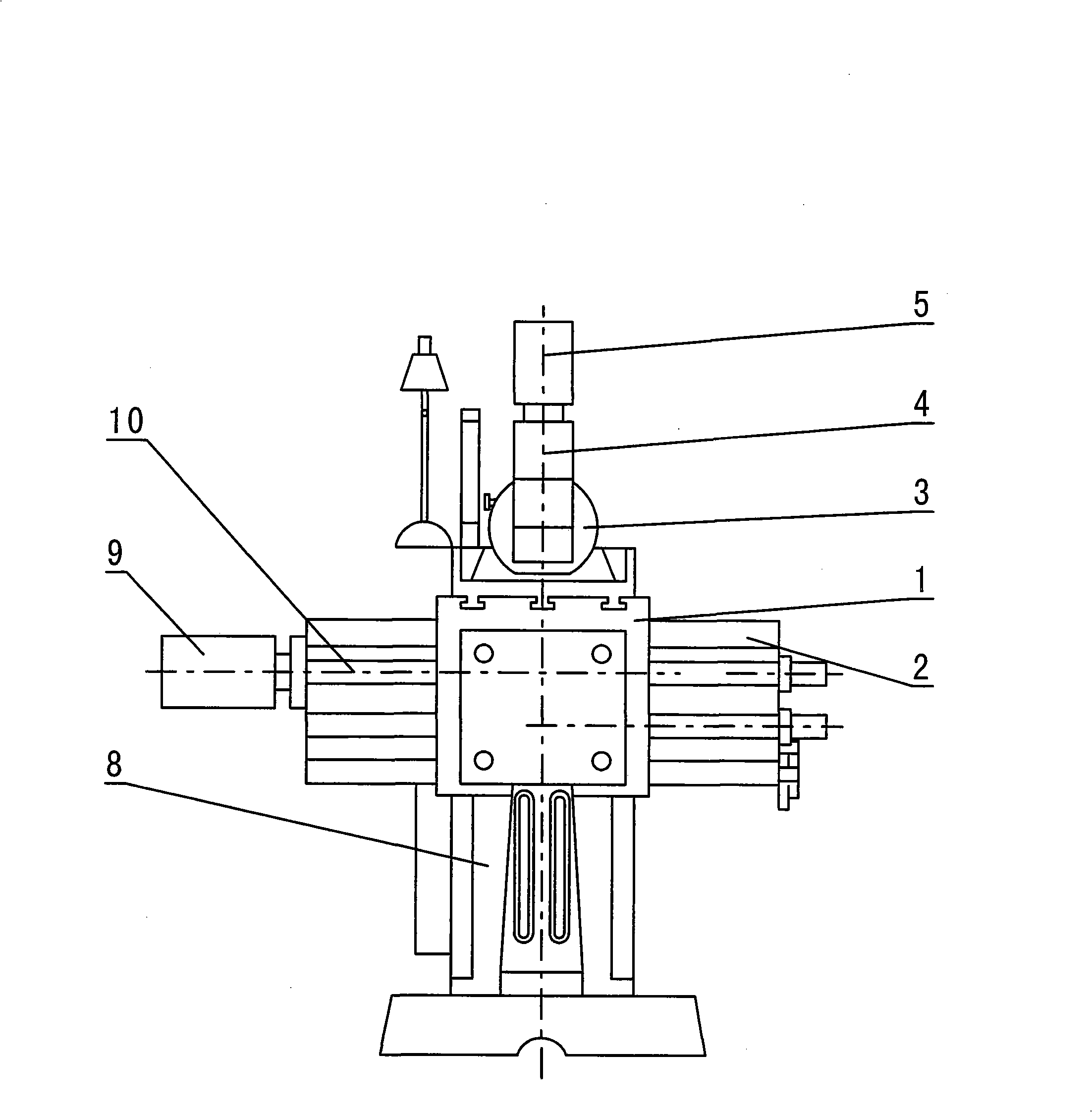

[0023] see figure 2 , a numerically controlled block planer, comprising a bed 8, a beam 2 arranged on the bed 8, a workbench 1 arranged on the beam 2, a workbench arranged at one end of the beam 2 The table feed servo motor 9, the table rotating lead screw 10 that is connected with the output shaft of the table feed servo motor 9 and cooperates with the nut on the table 1. The workbench feed servo motor 9 drives the workbench 1 to feed through the workbench rotating lead screw 10 .

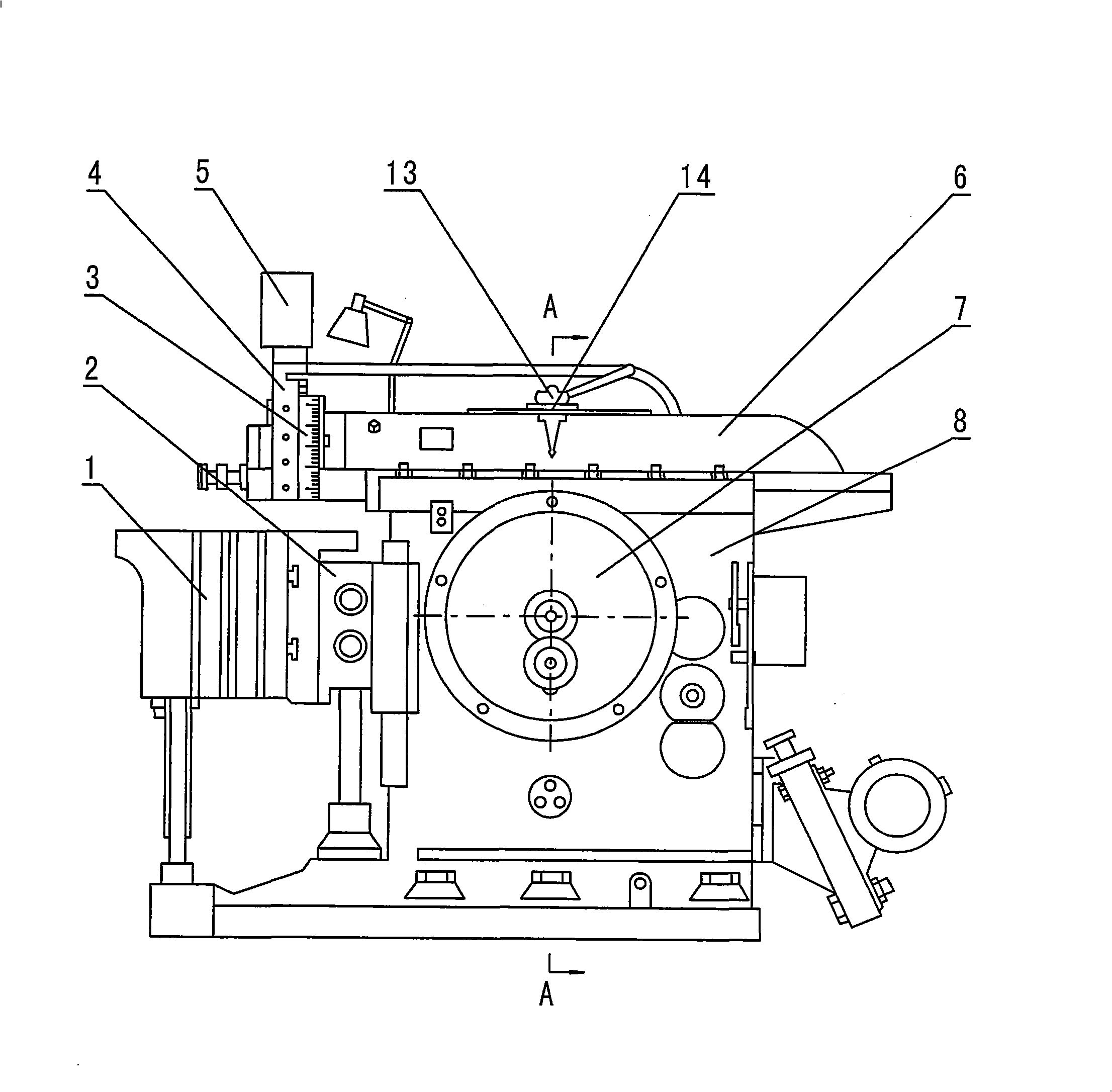

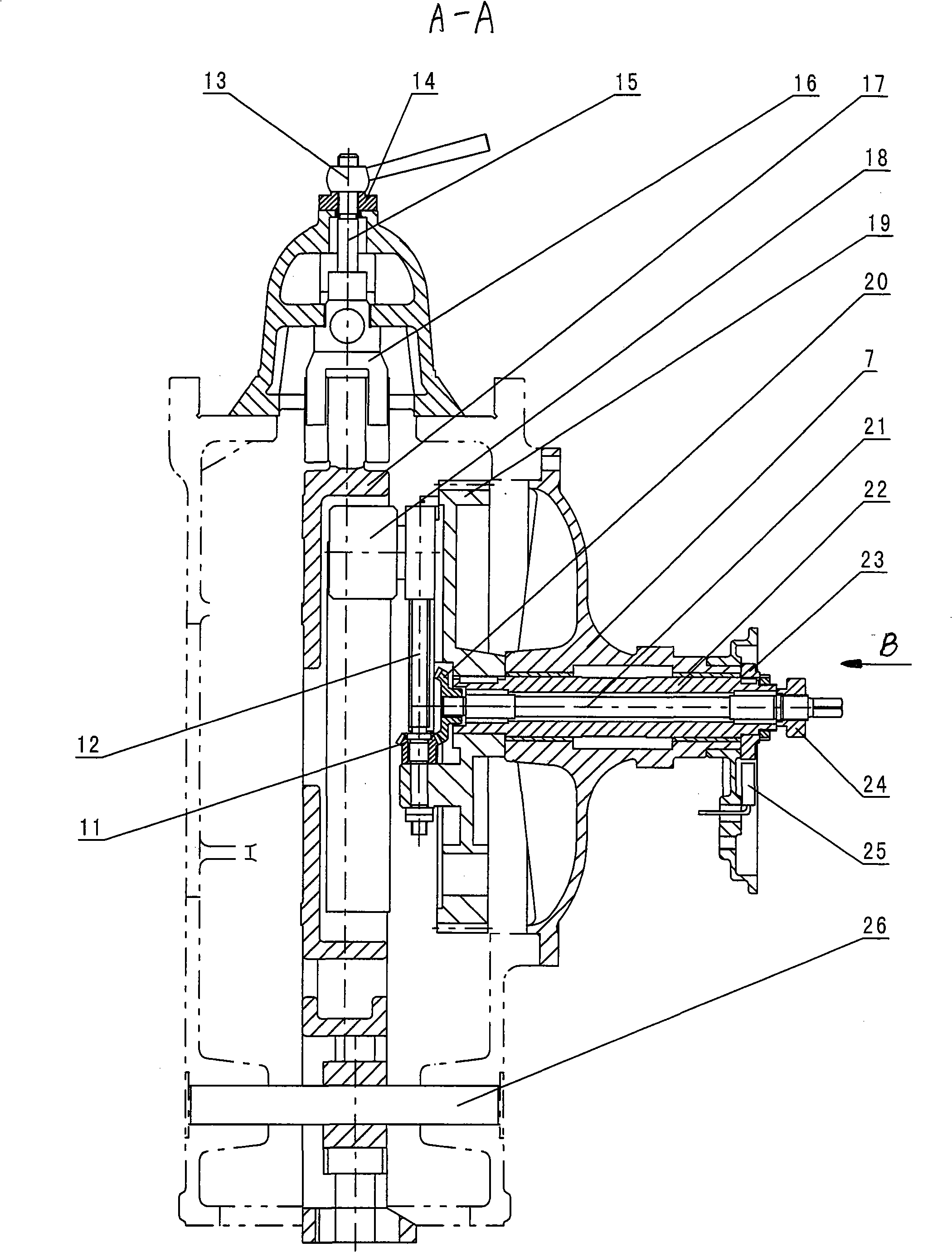

[0024] see figure 1 , Figure 4 , the CNC block planer also includes a ram 6 slidably arranged on the bed 8, a tool rest turntable 3 arranged at the front end of the ram 6, a tool rest turntable 3 arranged on the The knife rest slide plate 4, the knife rest feed servo motor 5 that is arranged on the top of the knife rest slide plate 4, is connected with the output shaft of the knife rest feed servo motor 5 and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com