Super large workspace spherical face hinge

A spherical hinge and working space technology, which is applied in the direction of manufacturing tools, manipulators, and pivot connections, can solve the problems of small working space, small swing range of the output rod, and small swing range of the output rod of the spherical hinge, so as to increase the swing work space, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

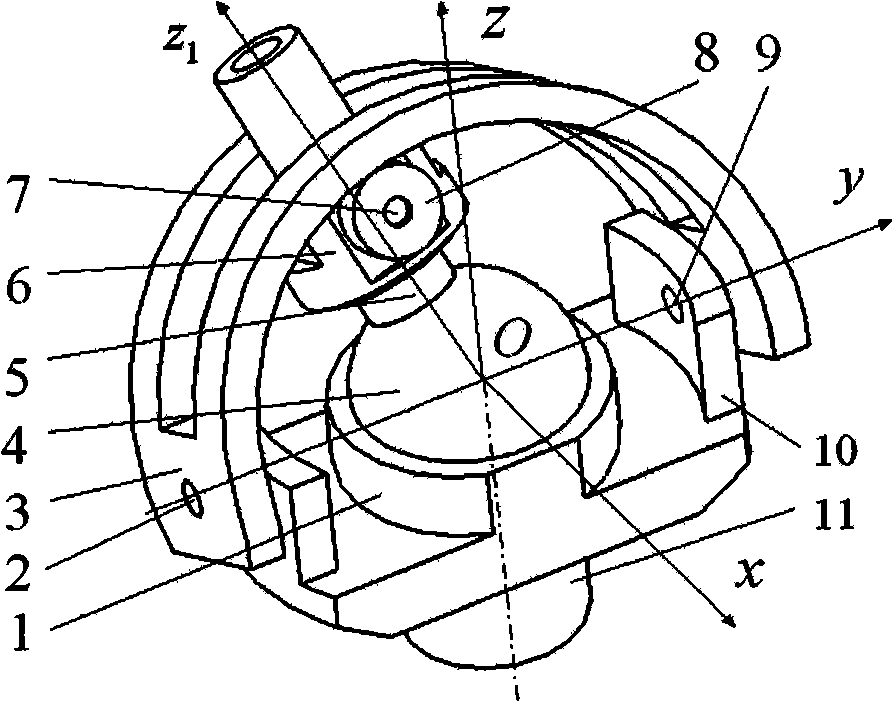

Embodiment 1

[0020] figure 1 It is the first embodiment disclosed by the present invention, and it is a new type of spherical hinge with a double-ear bracket fixed type and a large working space. It consists of a support unit, an output unit and a spherical sub-unit. The support unit includes a double-ear bracket 10, a lower support rod 11 and a U-shaped shift fork 3 and a pin shaft (2, 9) that forms a rotational connection with the double-ear bracket 10. The output unit includes an output rod 5, a rotating bracket 6, support pins (7, 7') and support rollers (8, 8'). The spherical sub-unit includes a supporting ball socket 1 , a ball head 4 and a U-shaped shift fork 3 . Wherein, the double-ear bracket 10 is fixedly connected with the lower support rod 11 as a whole, and is fixed with the support ball socket 1 at the coincident point of the ball center of the ball socket and the ball center of the hinge at the same time, and the rotation axis of the support ball socket 1 is connected with...

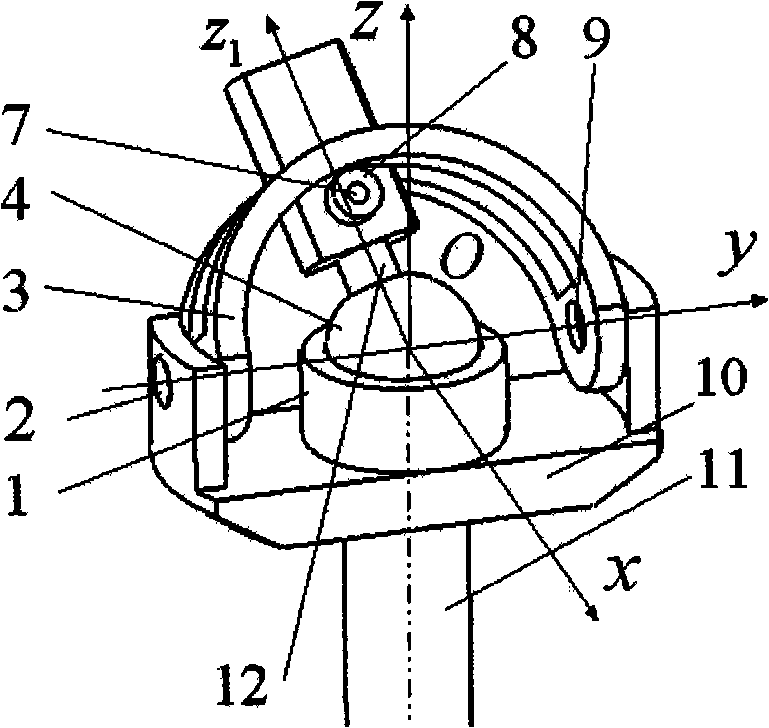

Embodiment 2

[0029] figure 2 It is the second embodiment disclosed by the present invention, and it is a new type of spherical hinge with a large working space and a rotating double-ear bracket. It consists of support unit, output unit and spherical sub-unit. The support unit includes a double-ear bracket 10, a lower support rod 11 and a pin shaft (2, 9); the output unit includes a square output rod 12, a support pin shaft (7, 7') and a support roller (8, 8' ); the spherical sub-unit includes a supporting ball socket 1, a ball head 4 and a U-shaped shift fork 3. Wherein the difference with Embodiment 1 is: the double-ear support 10 can rotate unrestricted around the axis of the lower support rod 11 (the upper part is axially positioned); the U-shaped shift fork 3 is placed inside the double-ear support 10; the pin shaft ( 7, 7') and support rollers (8, 8') are directly installed and positioned with the square output rod 12 (removing the rotating bracket), and the axis of the pin shaft (...

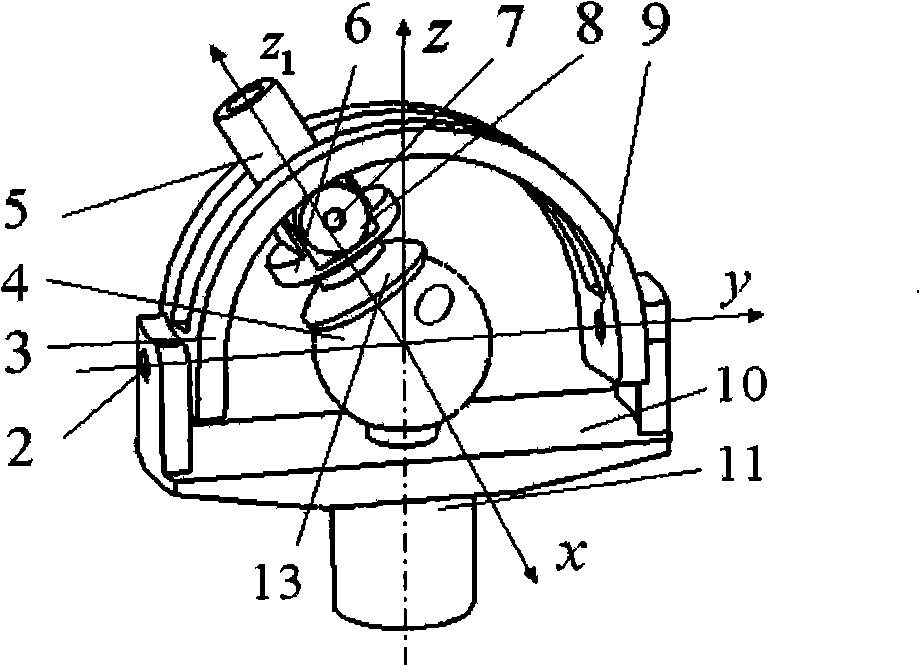

Embodiment 3

[0033] image 3It is the third embodiment disclosed by the present invention, and it is a new type of ball / socket transposition spherical hinge with a large working space. It consists of a support unit, an output unit and a spherical sub-unit, the support unit includes a double-ear bracket 10, a lower support rod 11 and a pin shaft (2, 9); the output unit includes an output rod 5, a rotating support frame 6, Support pin shafts (7, 7') and support rollers (8, 8'); Compared with Example 1, the difference is that: the position of the ball head 4 and the original supporting ball socket 1 are exchanged, and the lower supporting rod 11 is fixed at the center point of the ball, and the size of the supporting ball socket 1 is changed from the original hemispherical It is reduced to a ball gap, called the movable ball socket 13, which is fixed at the lower end of the output rod 5 (on the condition that the axis of the output rod coincides with the rotation axis of the movable ball soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com