Surface roughness recognizing and classifying method for LED chip

A technology of LED chip and surface roughness, which is applied in the field of identification and classification of the surface roughness of LED chips, can solve the problems of LED chip positioning operation troubles and other problems, achieve uniform brightness and avoid the effect of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

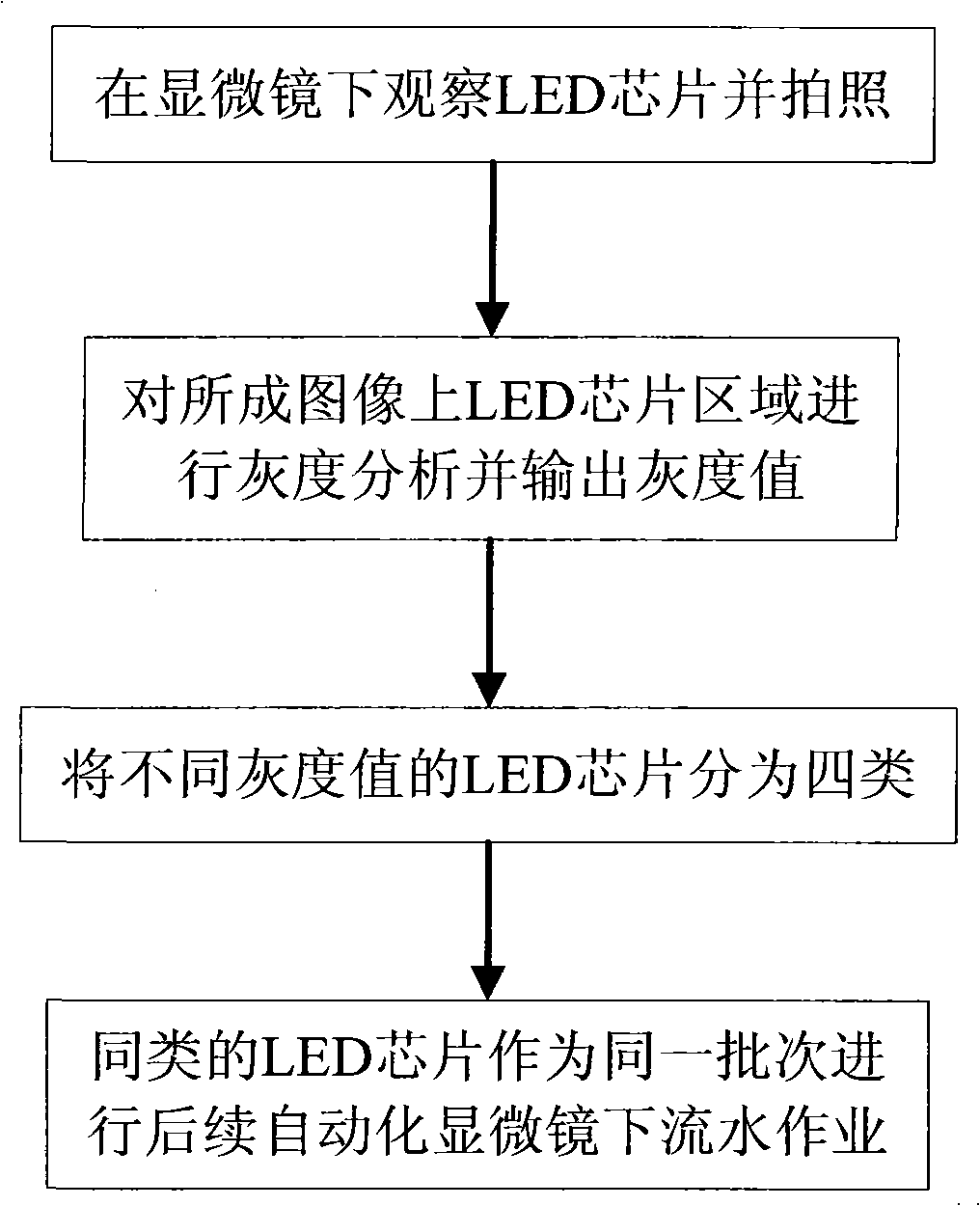

[0013] The identification and classification method of the LED chip surface roughness of the present invention is accomplished by a microscope and a grayscale identification system. figure 1 Be the flow chart of the present invention, introduce the step of the present invention in detail below:

[0014] Step 1: First put the gallium nitride-based LED chip under the microscope, the magnification is 10 times, and the magnification of the automatic microscope machine usually used for production is the same. At this time, an area with a certain brightness observed under the microscope is the position of the LED chip. LED chips with different surface roughness show different brightness under the microscope. Then use the CC integrated with the microscope to take pictures of the microscope image and save it.

[0015] Step 2: Use the grayscale recognition system to carry out grayscale recognition on the P electrode area and N electrode area of the LED chip on the image saved in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com