Energy-saving booster box of stove for roasting tobacco

A technology for flue-cured tobacco and flue-cured tobacco, which is applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of polluted environment, low combustion efficiency, poor temperature control, etc., and achieves the effects of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

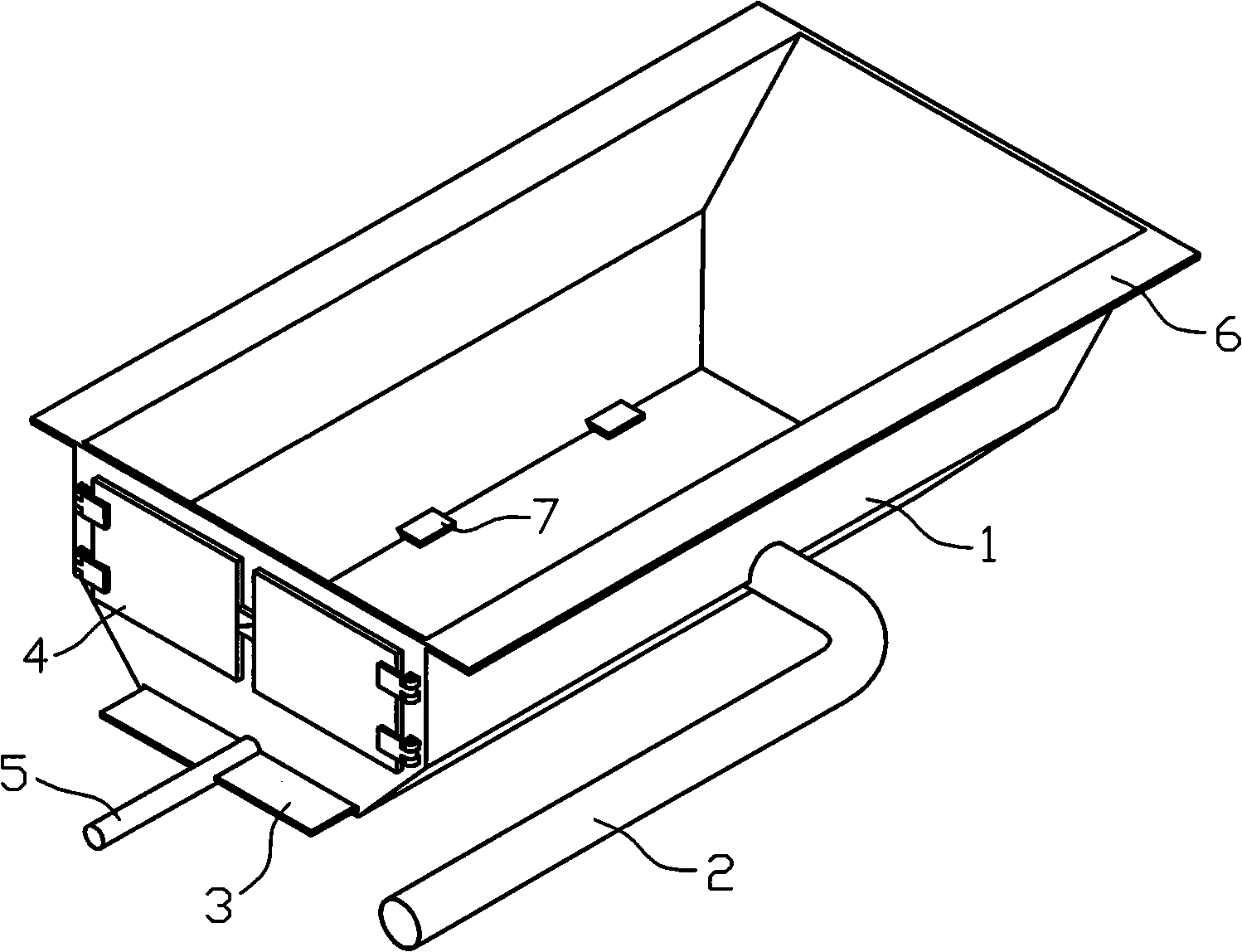

[0007] As shown in the drawings, it includes a box body 1, an air inlet pipe 2 and a plug-in plate 3. The box body 1 is a rectangular shell with openings on the top and bottom. 4. There is a sliding plate slideway at the bottom of the box body 1. The slideway can be bent from the side wall of the box body. The air inlet pipe 2 is connected to the side wall of the box body 1. The front part of the box body 3 is equipped with a handle. 5, the inserting plate 3 is plugged in at the bottom opening of the box body 1. The side wall of the box body 1 is provided with a restrained inclined surface, and the entire rear side wall is inclined. The two side walls of the box body 1 are provided with outwardly expanding fixing parts 6 . The side wall of the box body 1 is provided with a plugboard limiting piece 7 .

[0008] The present invention is directly installed and fixed under the hearth of the flue-cured furnace, and the air inlet pipe 2 is connected with the blower. During install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com