Mill deltoid device

A technology of flat square and lathe bed, applied in the field of flat square milling device, can solve the problems of difficulty in adjusting and straightening precision, influence of milling processing precision, high labor intensity of operators, etc., to reduce labor intensity, simple overall structure, and ensure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

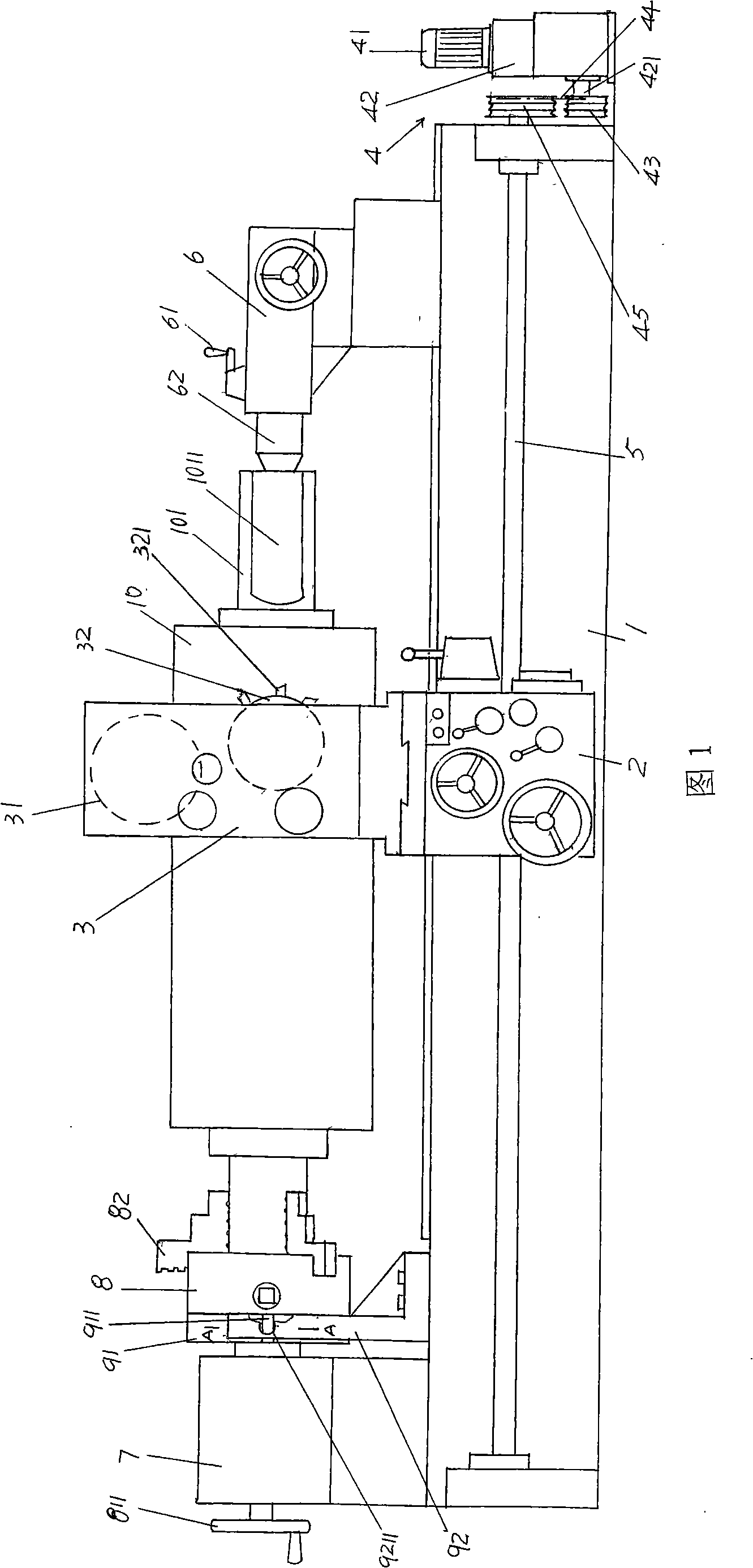

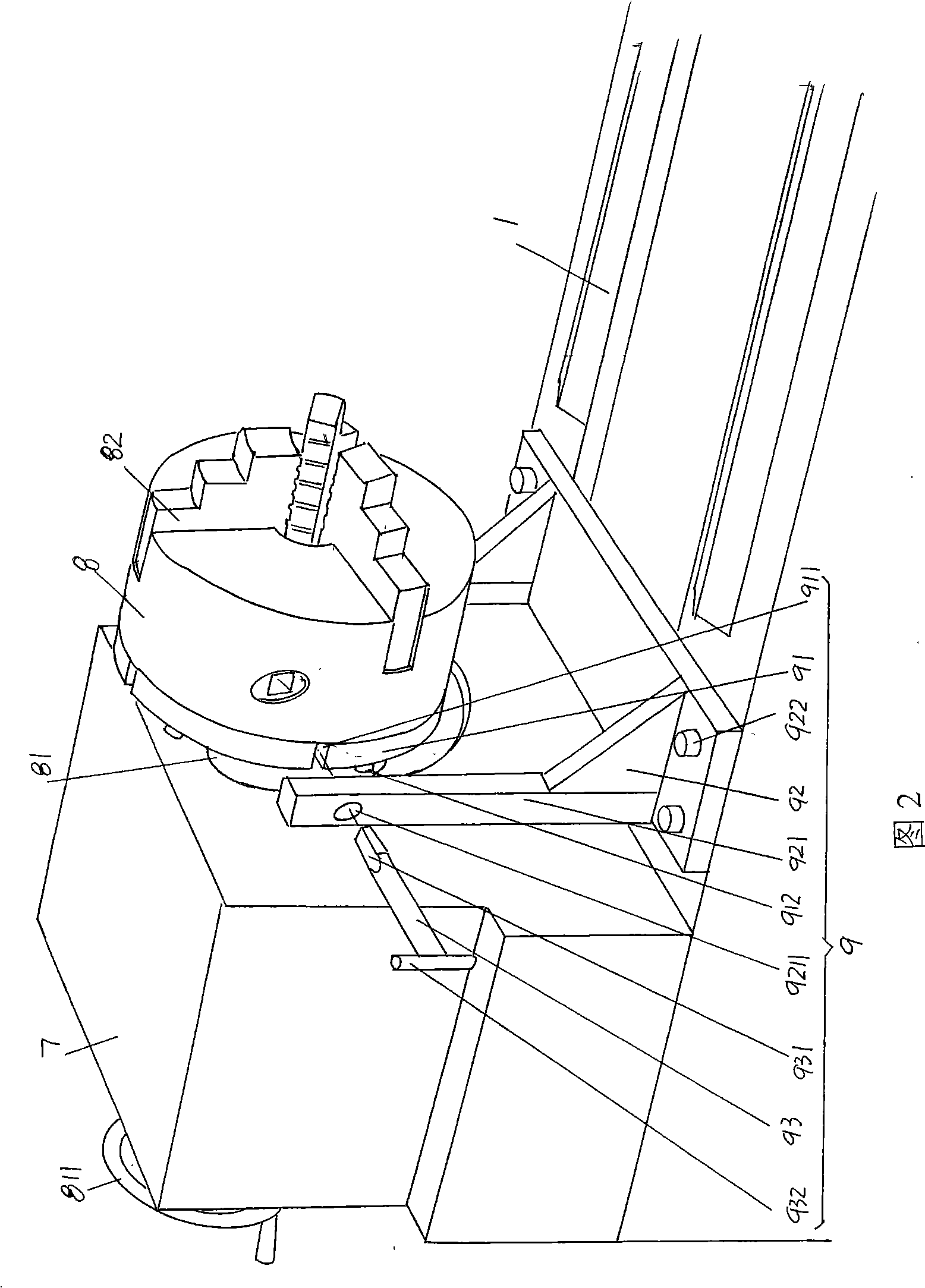

[0019] Please see Fig. 1, provided lathe bed 1, this lathe bed 1 adopts the bed of lathe in the prior art, and the mode of adopting has three, and the one, directly buy from lathe manufacturer, the 2nd, from discarded Take its bed on the lathe, the 3rd, buy the bed of the lathe from the second-hand equipment swap market, and the tool box 2 configured on the lathe bed 1 is the same example. The milling tool box 3 is installed on the tool box 2. For the milling tool box 3, it is recommended to use the milling tool box on the milling machine produced and sold by the milling machine manufacturer, for example, the model 3ZP I produced by China Shanghai Yongxin Milling Machine Co., Ltd. - Milling cutter box for type 2 milling machines. This milling cutter box 3 is equipped with motor 31 (ie motor) and plane milling cutter disc 32. In view of the above description, it can be seen that the lathe bed 1, milling, and tool boxes 2, 3 are all prior art, so the applicant no longer makes s...

Embodiment 2

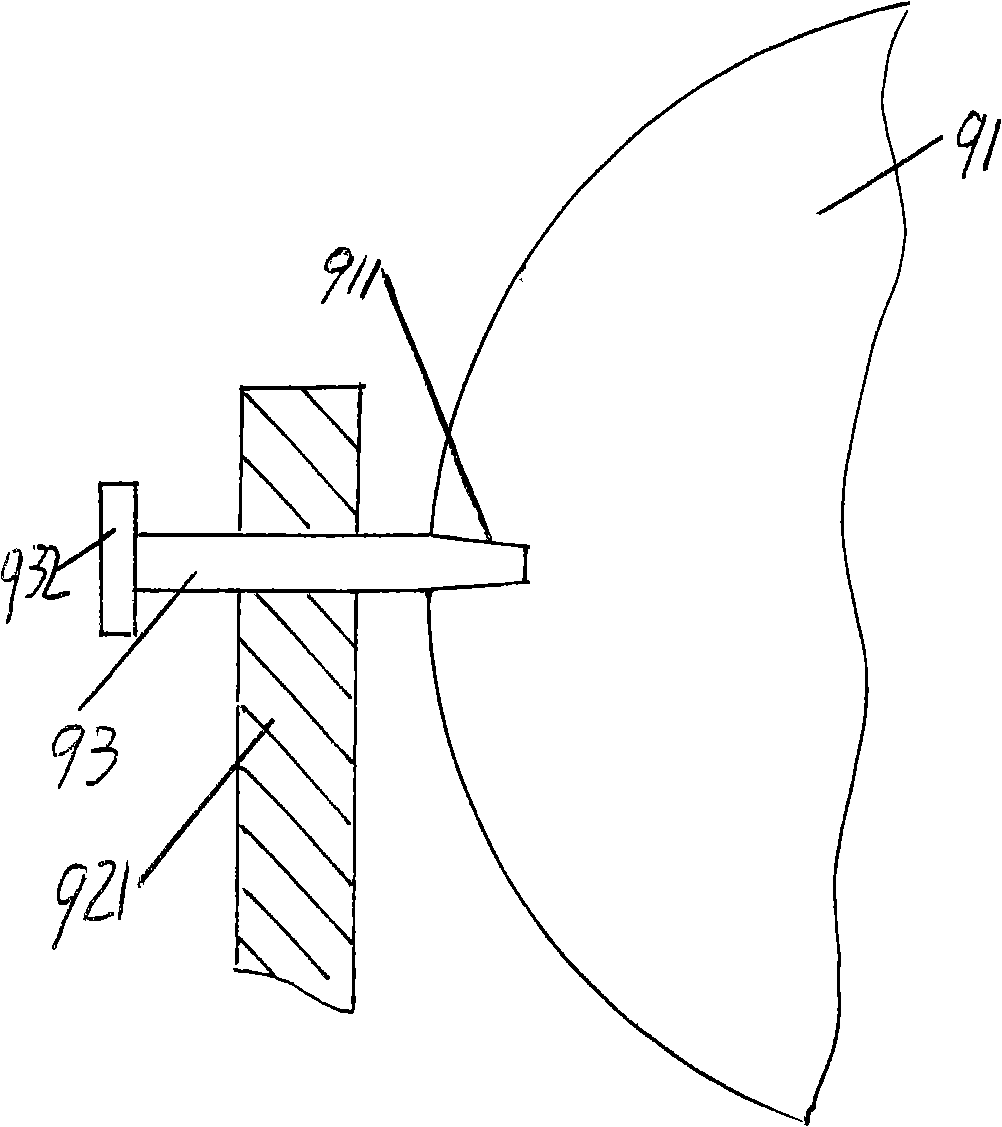

[0025] please see Figure 4 In addition to the four first indexing grooves 911 as described in Embodiment 1, a second indexing groove 913 and a third indexing groove 914 are provided on the edge of the indexing plate 91 . Form an angle of 15° between the second indexing groove 913 and one of the first indexing grooves 911 in the four first indexing grooves 911; and the third indexing groove 914 and the four first indexing grooves 911 One of the first indexing grooves 911 forms an included angle of 45°. More specifically, the four first indexing grooves 911 described in Embodiment 1 are provided at four equal divisions of the circumference of the indexing plate 91, that is, four equal divisions of the circumference of the indexing plate 91 are respectively opened. A first indexing groove 911, therefore, the second indexing groove 913 in the present embodiment is to be opened at the two fourteen equal parts of the circle of the indexing plate 91, the same example, the third ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com