Manufacture method of heat-tolerance poly-lactic resin ejection formed piece

A technology of polylactic acid resin and manufacturing method, which is applied in the field of manufacturing heat-resistant polylactic acid resin injection molded products, can solve the problems of poor process efficiency, high cost of injection molded products, limited process efficiency, etc. Excellent heat resistance and mechanical strength, and the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in detail:

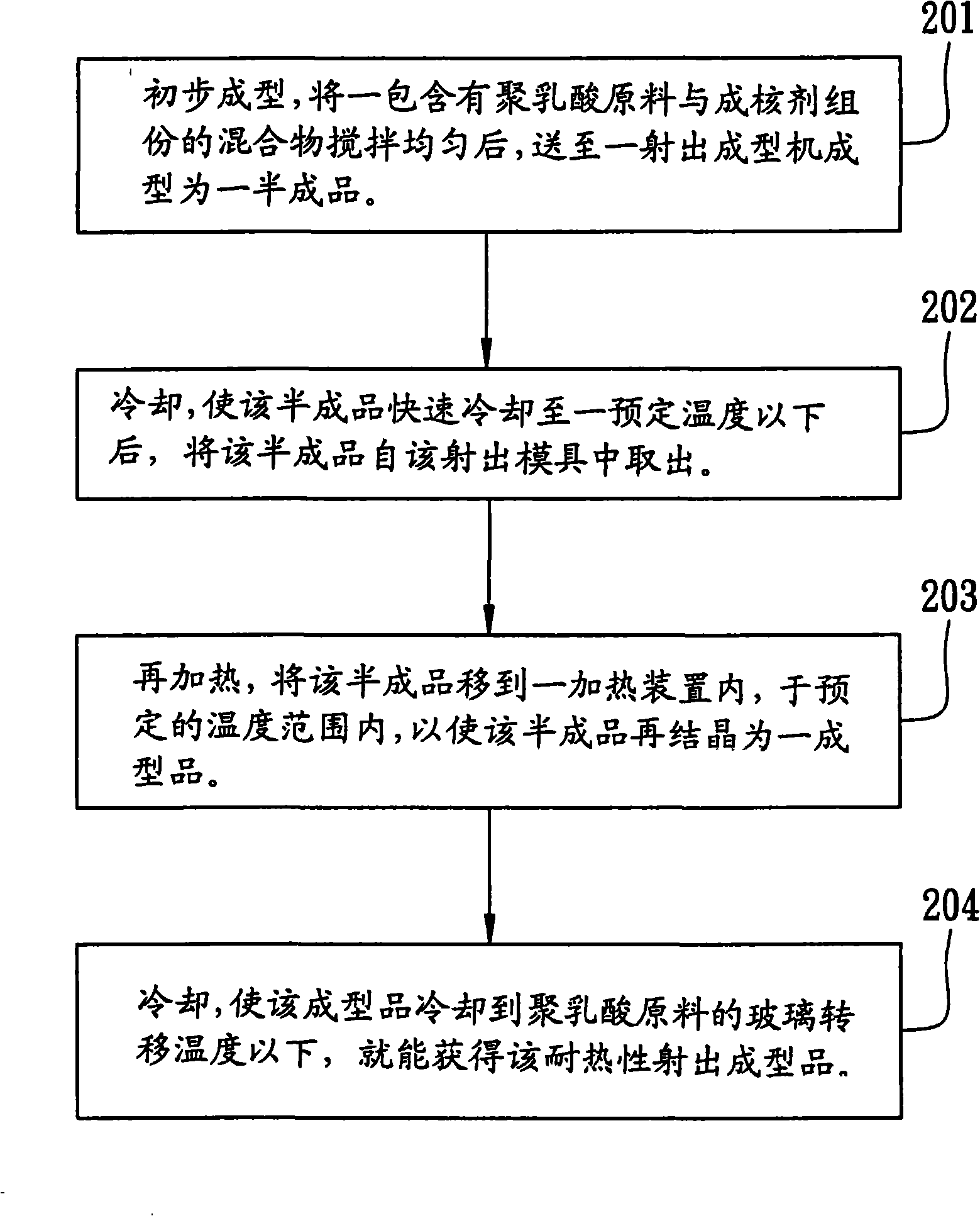

[0022] refer to figure 2 , the manufacturing method of heat-resistant polylactic acid resin injection molded article of the present invention-a first preferred embodiment, comprises the following steps:

[0023] Step 201 is preliminary molding, which is to mix a mixture containing polylactic acid raw materials and nucleating agent components evenly, and then send it to an injection molding machine and cooperate with an injection mold to form a semi-finished product.

[0024] Wherein, the nucleating agent can be an organic nucleating agent or an inorganic nucleating agent according to the process design and product specifications, and the inorganic nucleating agent is a material selected from the following group: clay (clay), mica (mica) , silicates, calcium carbonate (CaCO3), silicon dioxide (silica), talc (talc), and combinations thereof. Moreover, the nucleating agent component is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com