Process for removing bio foam in sewage disposal process by activated sludge process

An activated sludge method and sewage treatment technology, applied in the field of environmental engineering water treatment, can solve the problems of adding chemical agents, affecting denitrification, and deteriorating effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

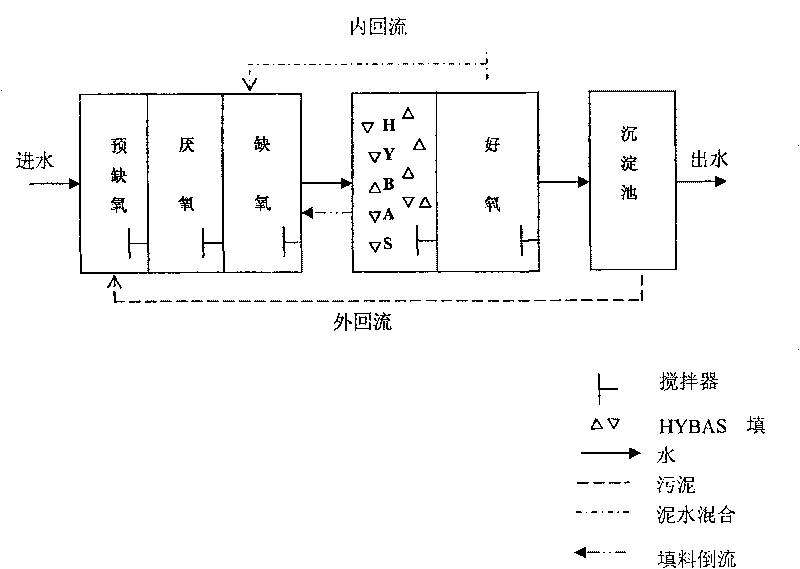

[0022] An activated sludge sewage treatment process, the activated sludge sewage treatment process includes a pre-anoxic reaction unit, anaerobic reaction unit, anoxic reaction unit, suspended packing aeration tank reaction unit and aerobic reaction unit, each reaction The units are all equipped with submersible mixers, and the reaction unit of the suspended filler aeration tank is put into 10m 3 The filling ratio is 30% of the total volume of the reaction unit, and the treated water volume of the activated sludge sewage treatment process sewage plant is 280m 3 / d, operate according to the process design parameters with an internal reflux ratio of 200% and an external reflux ratio of 100%. The sludge age of the process is 10 days, and the sludge concentration is 4500mg / L. After the biofoam is generated, the microscopic examination shows that the filamentous bacteria are abundant.

[0023] The specific steps of this process to remove biofoam are as follows:

[0024] (1) After...

Embodiment 2

[0030] An activated sludge sewage treatment process, the activated sludge sewage treatment process includes a pre-anoxic reaction unit, anaerobic reaction unit, anoxic reaction unit, suspended packing aeration tank reaction unit and aerobic reaction unit, each reaction The units are all equipped with submersible mixers, and the reaction unit of the suspended filler aeration tank is put into 10m 3 The filling ratio is 30% of the total volume of the reaction unit, and the treated water volume of the activated sludge sewage treatment process sewage plant is 280m 3 / d, operate according to the process design parameters with an internal reflux ratio of 200% and an external reflux ratio of 100%. The sludge age of the process is 10 days, and the sludge concentration is 4500mg / L. After the biofoam is generated, the microscopic examination shows that the filamentous bacteria are abundant.

[0031] The specific steps of this process to remove biofoam are as follows:

[0032] (1) Adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com