Acrylic resin with self-crosslinking characteristic and method for preparing same

An acrylic resin, self-crosslinking technology, applied in the direction of coating, can solve the problems of incompatible coating film gloss, inconvenient application, poor appearance effect, etc., to achieve the effect of wide application field and excellent use characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

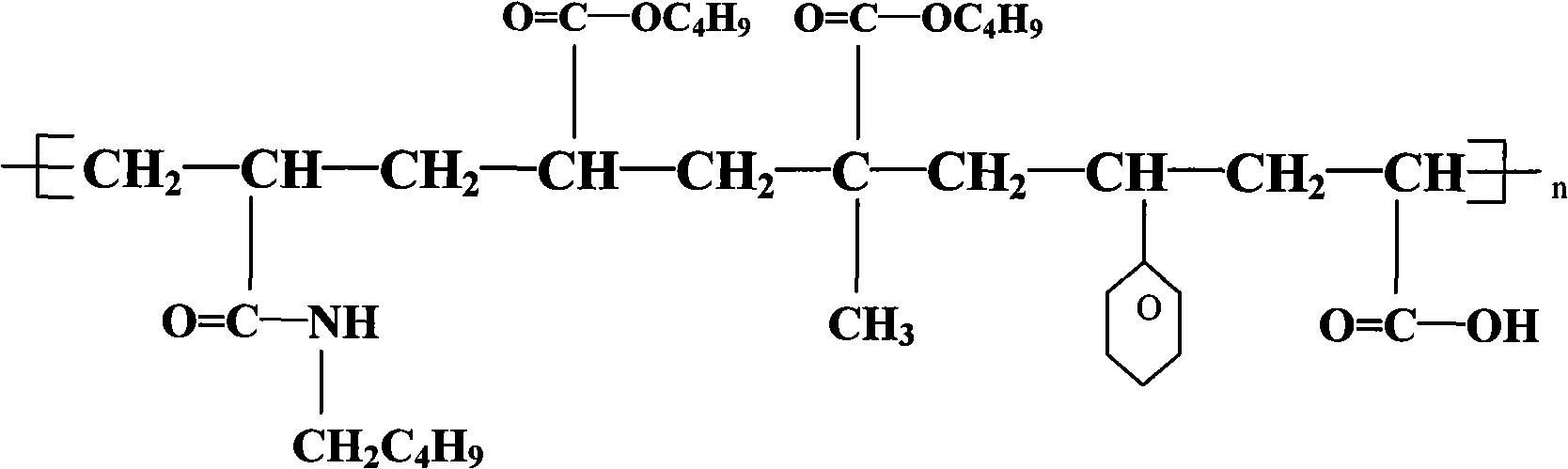

Image

Examples

Embodiment Construction

[0023] An acrylic resin with self-crosslinking characteristics, which is made of the following raw materials in weight percentage: n-butanol 25-30%, xylene 10-16%, polyoxymethylene 2-5%, acrylamide 4-7% , Butyl methacrylate 12 to 18%, butyl acrylate 15 to 20%, acrylic acid 2 to 5%, styrene 12 to 16%, U626 antioxidant 0.1 to 0.3%, BOP 0.6 to 1.5% and butyl acetate Ester 4-8%.

[0024] The polyoxymethylene used in the present invention is a raw material imported from Germany, and the BPO requirements are produced by French Atofile Company. In addition, the n-butanol has a water content of ≤0.1% and a purity of ≥99.5%, the butyl acrylate and butyl acrylate , The purity of acrylic acid and styrene ≥99%.

[0025] The best weight percentage of an acrylic resin with self-crosslinking characteristics: n-butanol 27%, xylene 12%, polyoxymethylene 3%, acrylamide 5%, butyl methacrylate 14%, butyl acrylate 16% , Acrylic acid 3%, styrene 14%, U626 antioxidant 0.2%, BOP 0.8% and butyl acetate 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com