Hermetic electric submersible pump production completion system capable of proceeding steel wire operation

A technology of electric submersible pump and steel wire, which is applied in the direction of flushing wellbore, sealing/packing, wellbore/well components, etc., can solve the problems of long operation time, complicated operation, and high requirement of anti-airlock performance of electric submersible pump, etc. To achieve the effect of improving oil well productivity and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

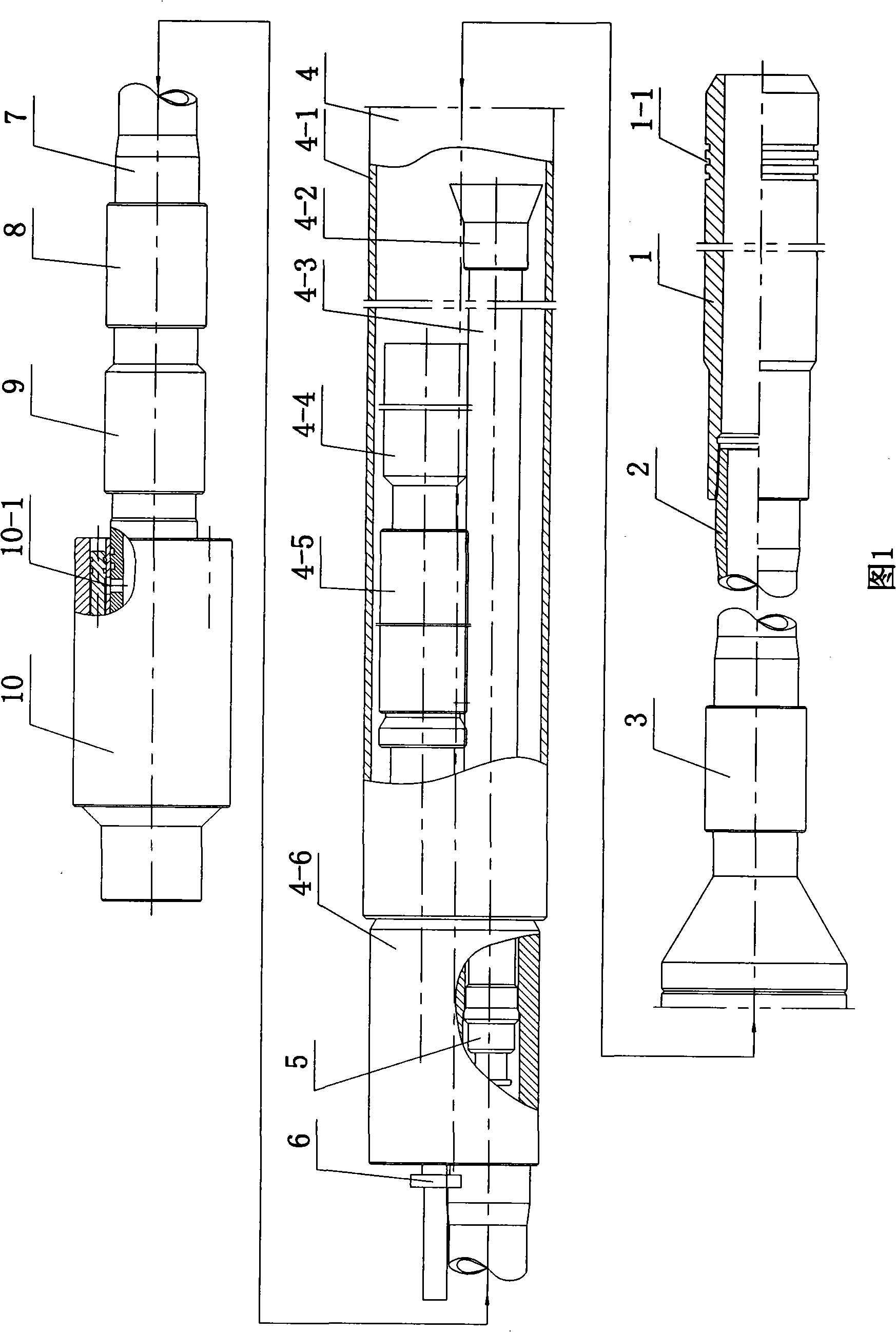

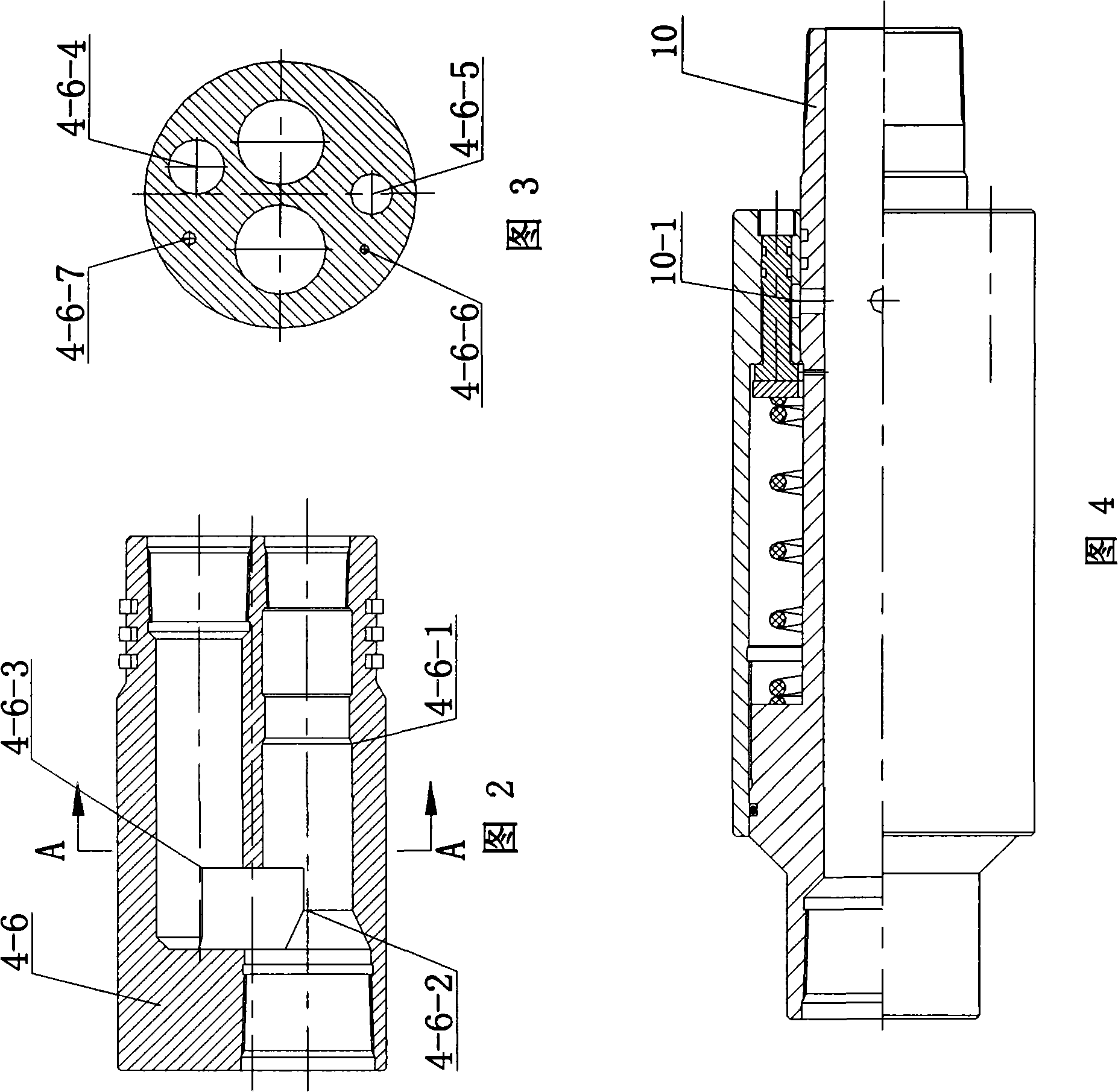

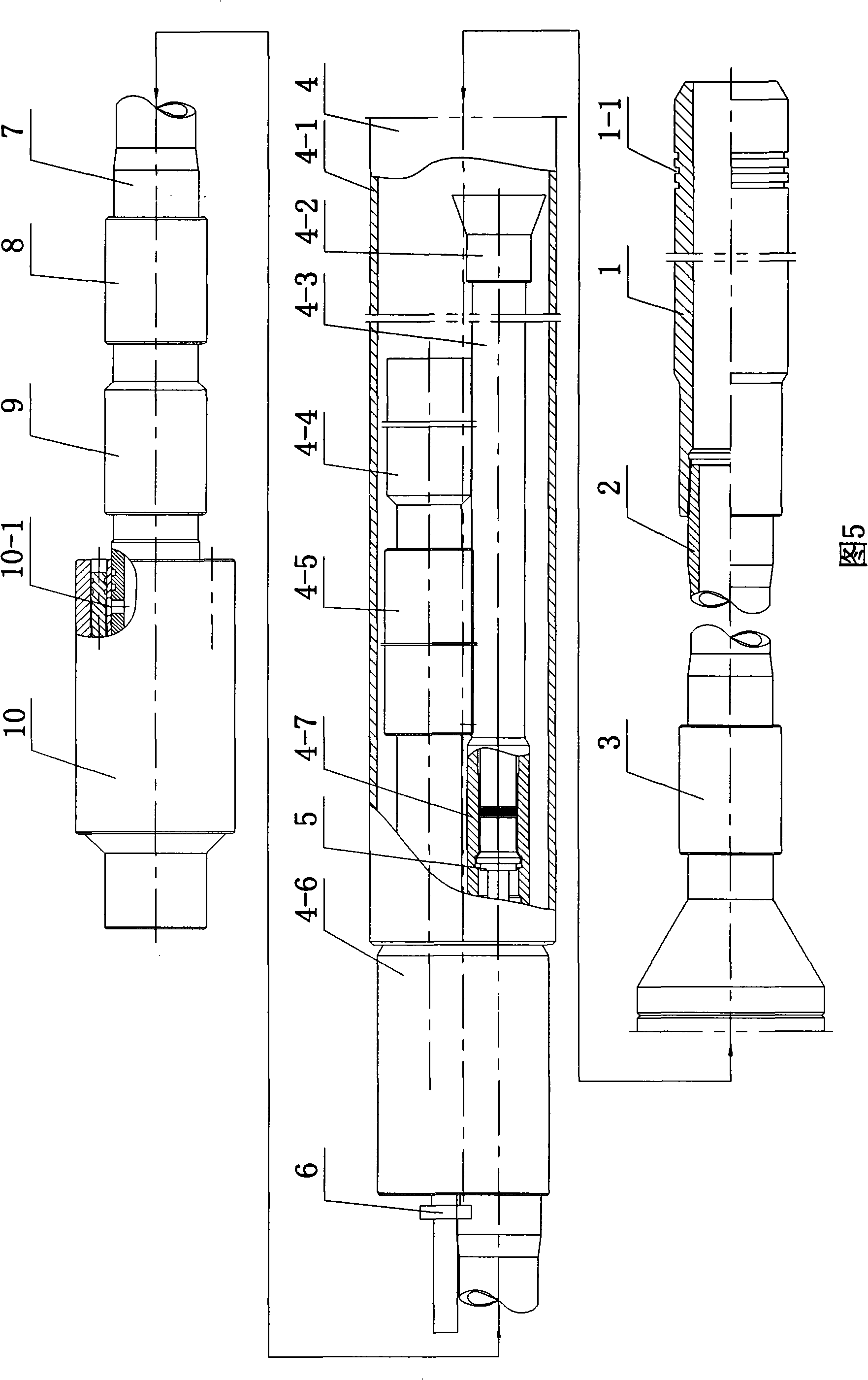

[0021] Please refer to Fig. 1-Fig. 5, the production and completion system of the closed electric submersible pump for steel wire operation mainly includes: production insertion head 1, tubing 2, coupling 3, closed electric submersible pump assembly 4, plug 5 and The ball seat pup joint 9, wherein the sealed electric submersible pump assembly 4 includes the shroud 4-1, the guide head 4-2, the oil pipe 4-3, the electric submersible pump unit 4-4, the expansion joint 4-5 and the sealed electric submersible The pump hanger assembly 4-6, the airtight electric submersible pump hanger assembly is an integral structure, which is equipped with a lower main pipe 4-6-2 and a lower side pipe 4-6-3, hanging on the airtight electric submersible pump Cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com