Compressor exhaust temperature control device and its control method and applications

A technology of compressor exhaust and control device, applied in the field of compressors, can solve the problems of slow start-up speed of greenhouse, unable to rise in room temperature, low air temperature, etc., and achieve the effects of cheap manufacturing cost, improved reliability and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

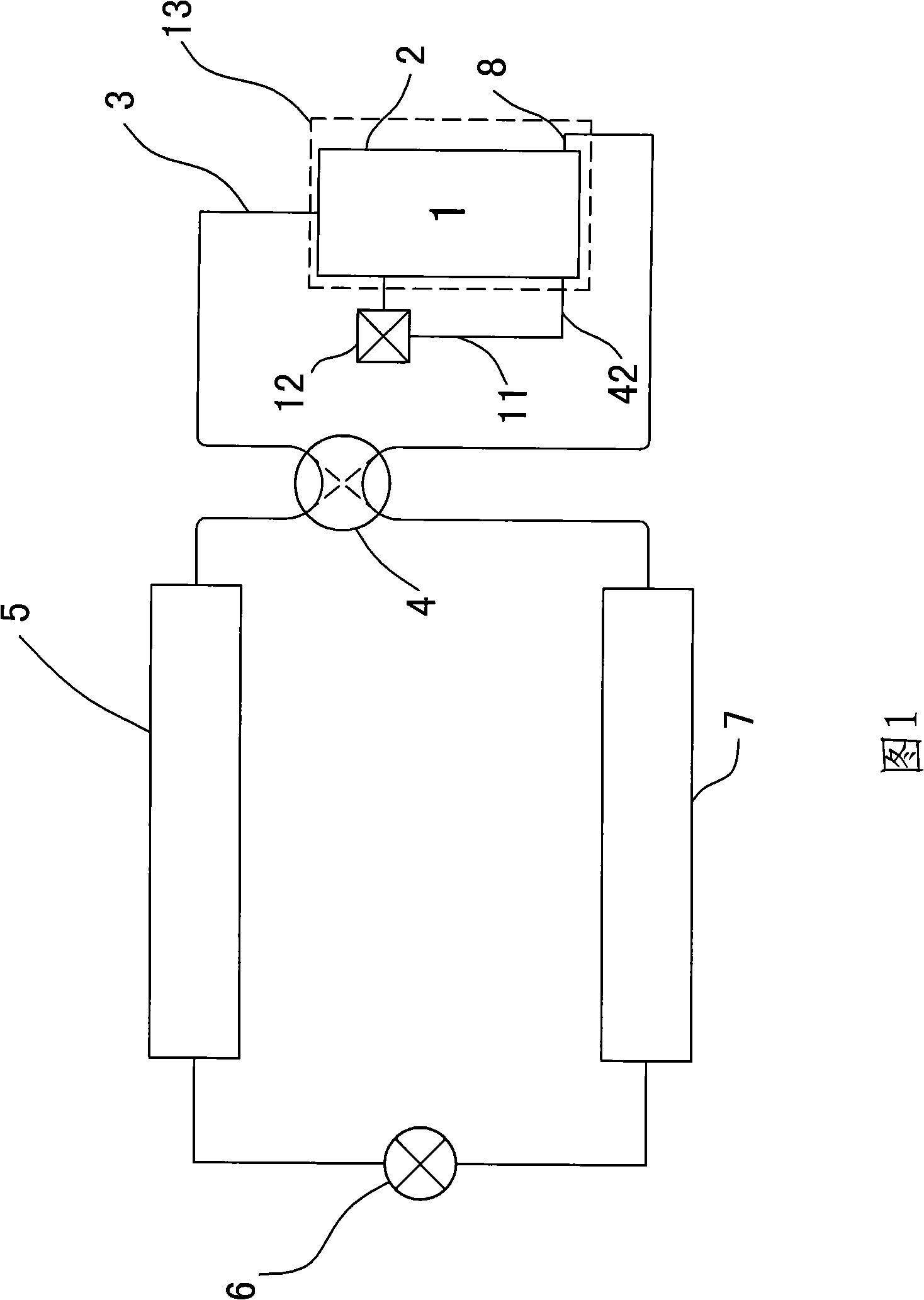

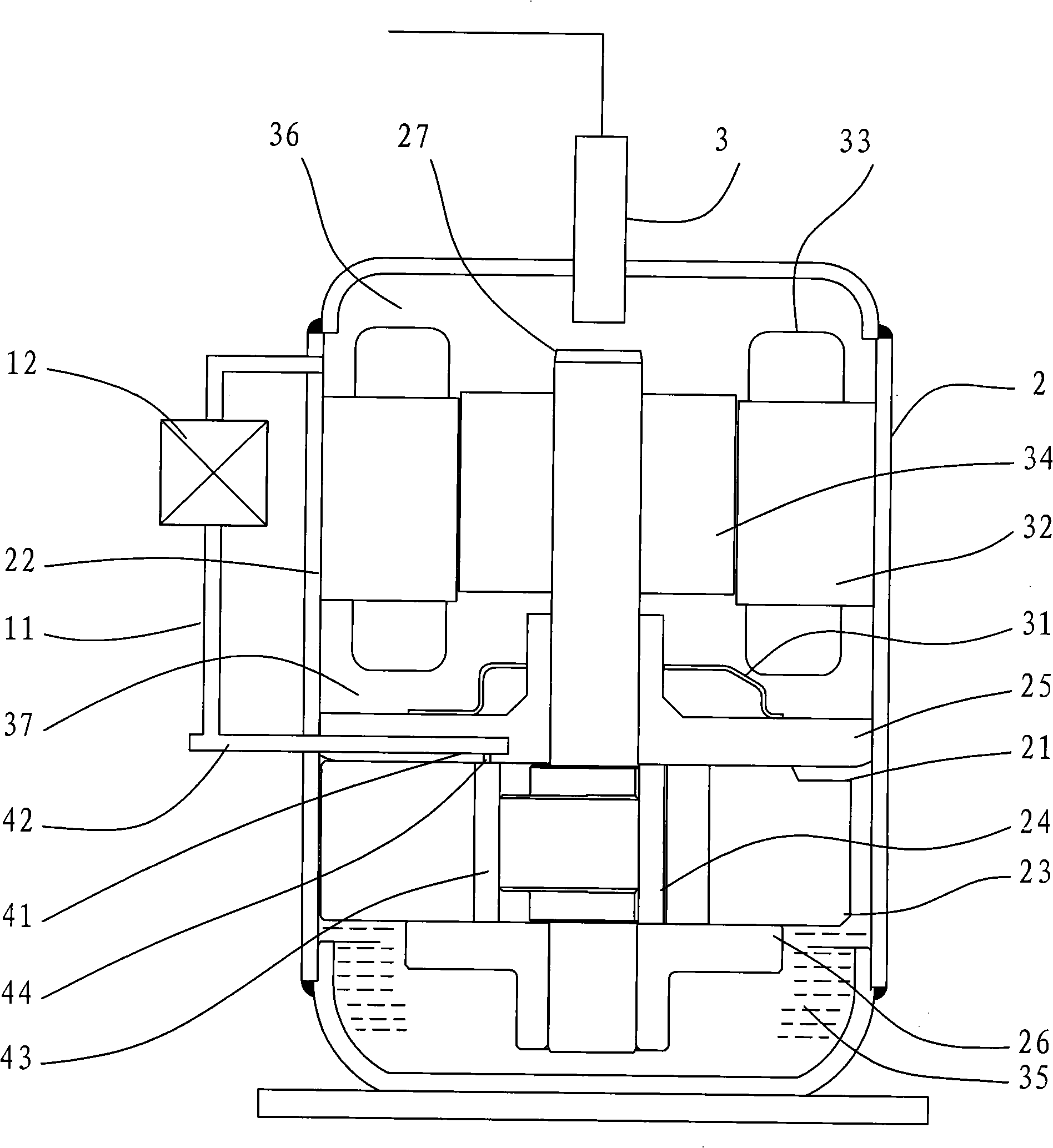

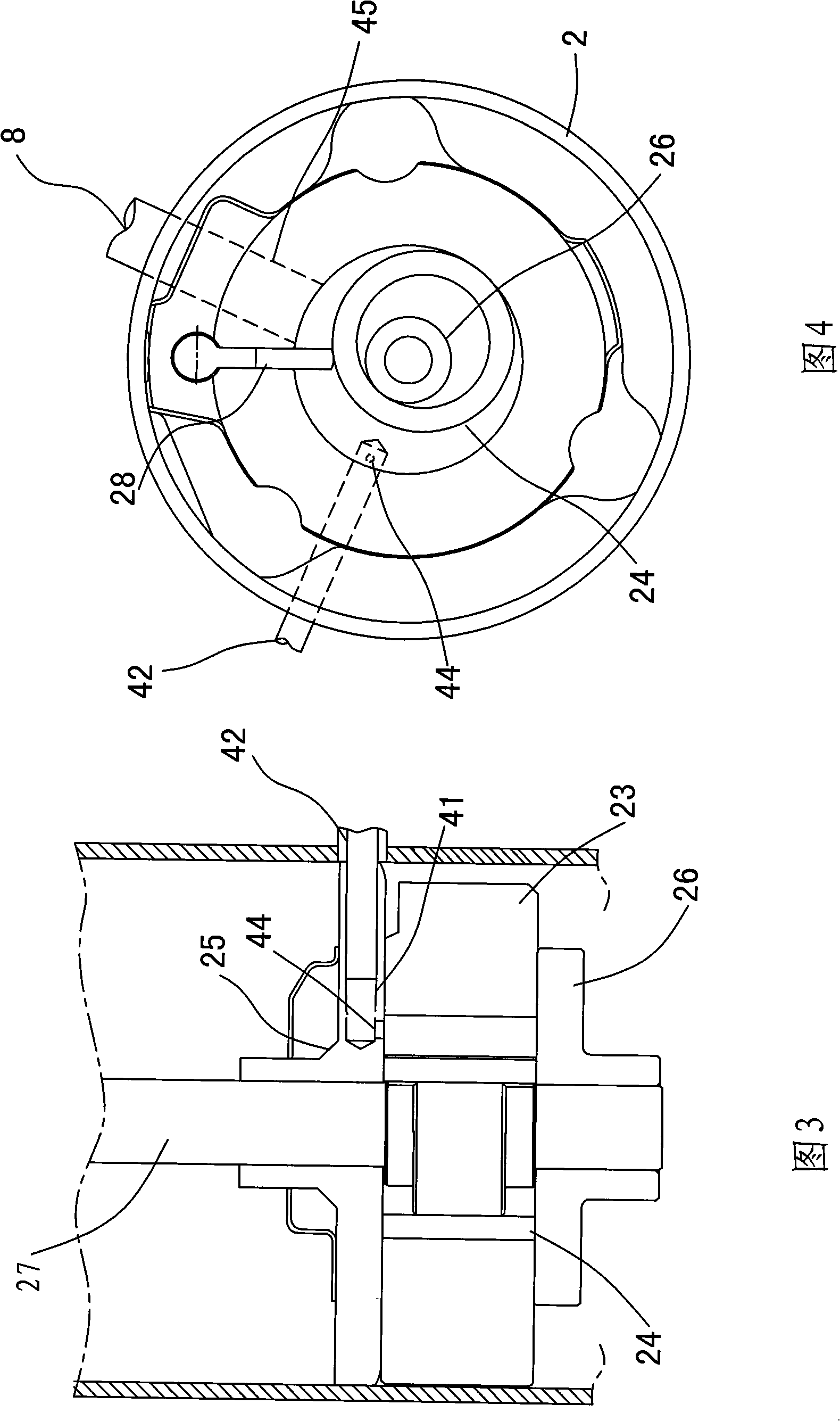

[0034] Referring to FIG. 1 , it is a structural schematic diagram of an air-conditioning system of a heating and cooling air conditioner using a rotary compressor 1 . The exhaust pipe 3 arranged on the upper end of the casing 2 of the compressor 1 is connected to the inlet of an indoor heat exchanger 5 through a four-way valve 4 . The outlet of the indoor heat exchanger 5 is connected to the inlet of the outdoor heat exchanger 7 through an expansion valve 6 . The outlet of the outdoor heat exchanger 7 is connected with the suction pipe 8 of the compressor 1 through the four-way valve 4 . Usually, in a system configured with a rotary compressor, a liquid reservoir (not shown) is provided between the outdoor heat exchanger 7 and the suction pipe 8, and the indoor heat exchanger 5 in the heating system is a condenser. The outdoor heat exchanger 7 is an ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com