Furnace cupola taphole blocking device

A technology for tapholes and cupolas, which is applied in the field of blocking devices, can solve the problems of labor or material loss, molten iron splashing, scalding operators, etc., and achieve the effects of facilitating safe production, reducing labor intensity, and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

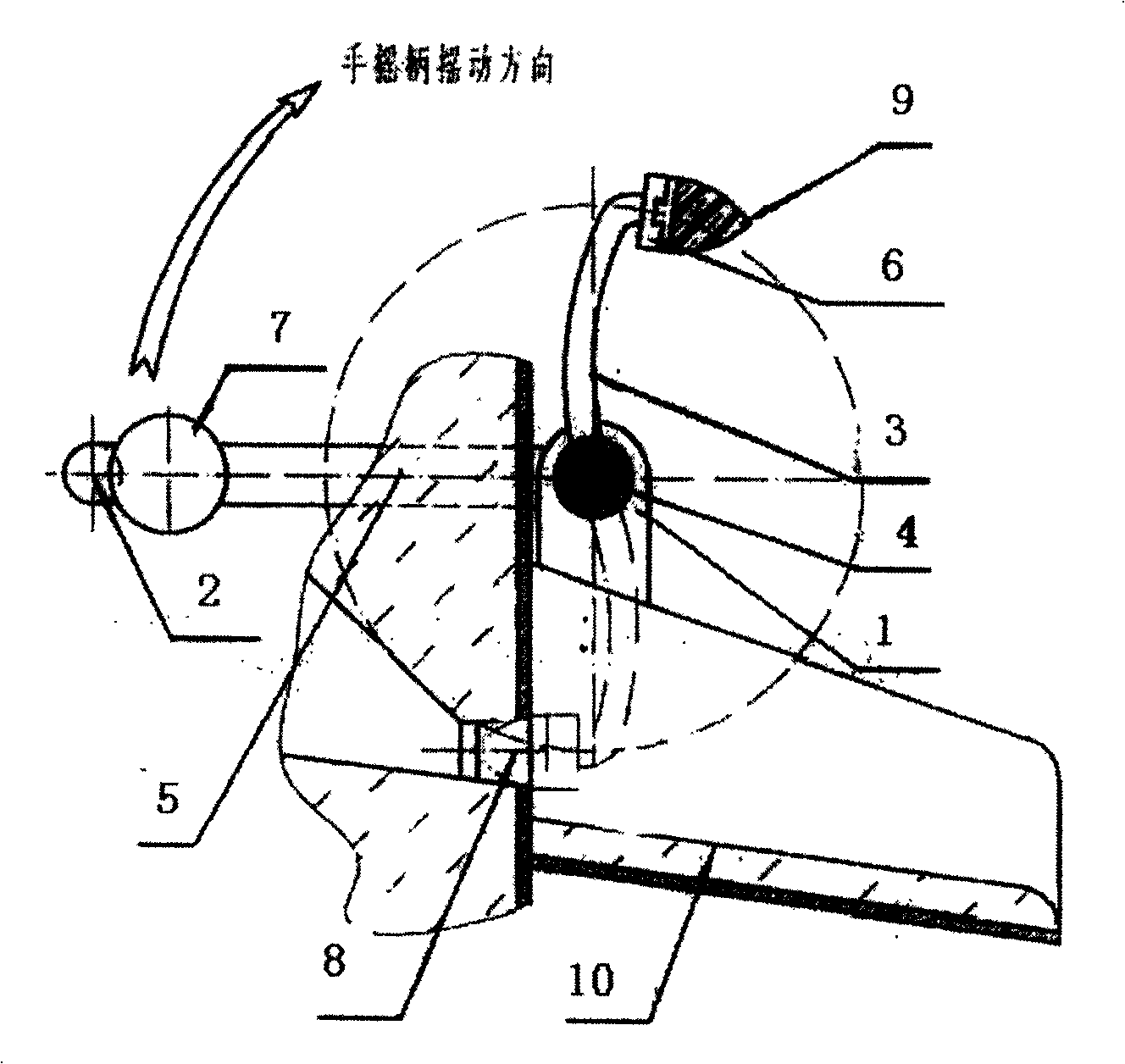

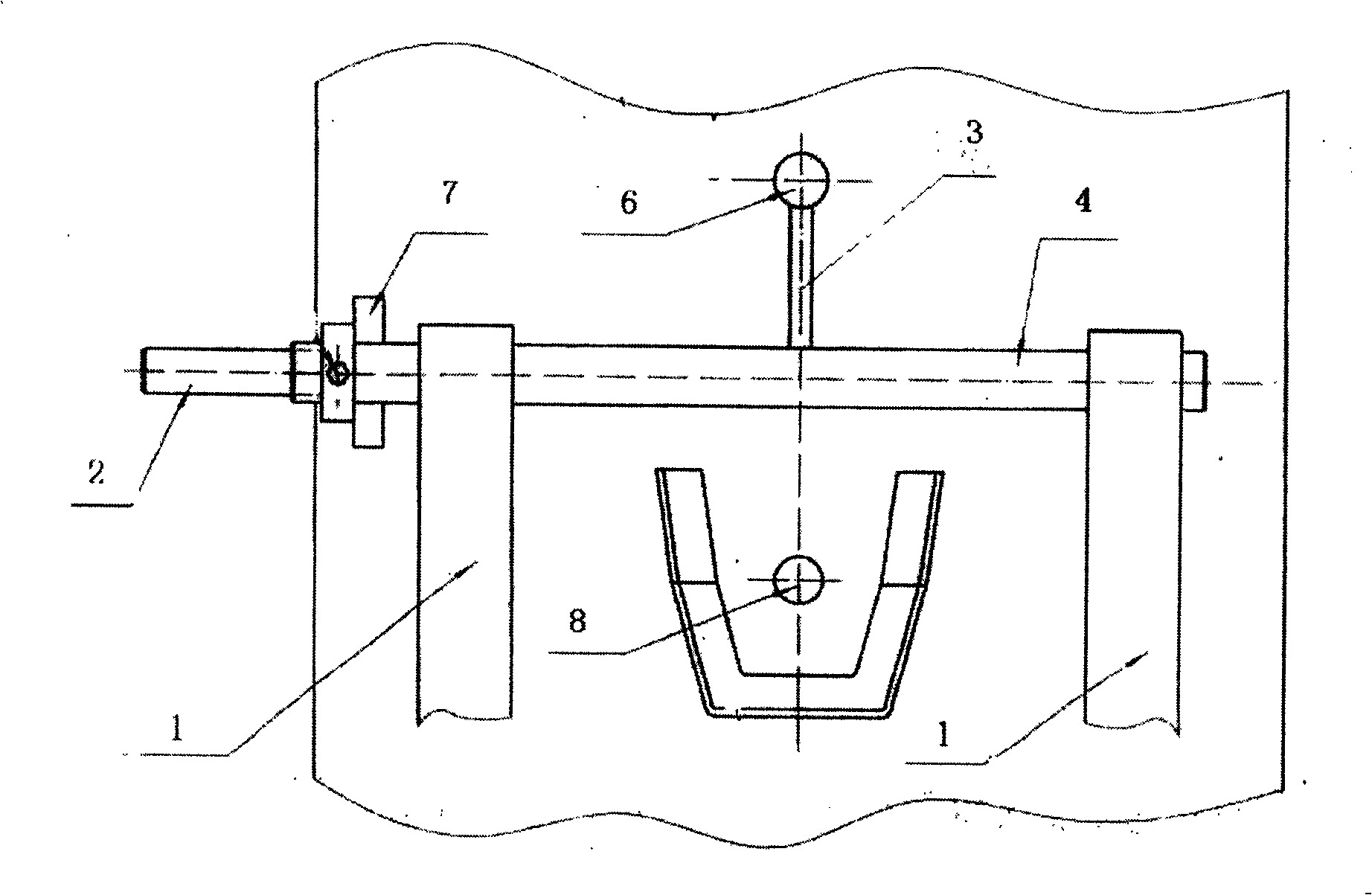

[0011] combine figure 1 , figure 2 The present invention is further described in detail. The blocking device of the cupola taphole includes a support 1, a hand crank 2, a mud plug rod 3, a rotating shaft 4, and a rotating arm 5. The support 1 is fixed on the cupola taphole 8. Both sides, rotating shaft 4 is horizontally installed on the bracket 1 and is movable connection, and one end of mud plug rod 3 is vertically connected with the center position of rotating shaft 4, and the other end of mud plug rod 3 is provided with mud plug seat 6, and hand-operated Handle 2 links to each other with rotating shaft 4 through rotating arm 5, and rotating arm 5 is provided with counterweight 7, and mud plug rod 3 can be arranged in arc shape, and counterweight 7 can be movably connected on rotating arm 5.

[0012] During the operation, to stop the molten iron in the tap trough 10 from flowing out, the operator fixes the refractory mud 9 on the mud plug seat 6, shakes the hand handle 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com