Electronic detonator control chip and its connection reliability checking method

A technology for controlling chips and electronic detonators, applied in the field of pyrotechnics, can solve problems such as the inability to detect the reliability of the external connection of the chip, the inability to detect components, and affect the anti-static and anti-radio frequency safety characteristics of the detonator, so as to achieve online repeated testing and avoid Energy consumption, the effect of improving the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

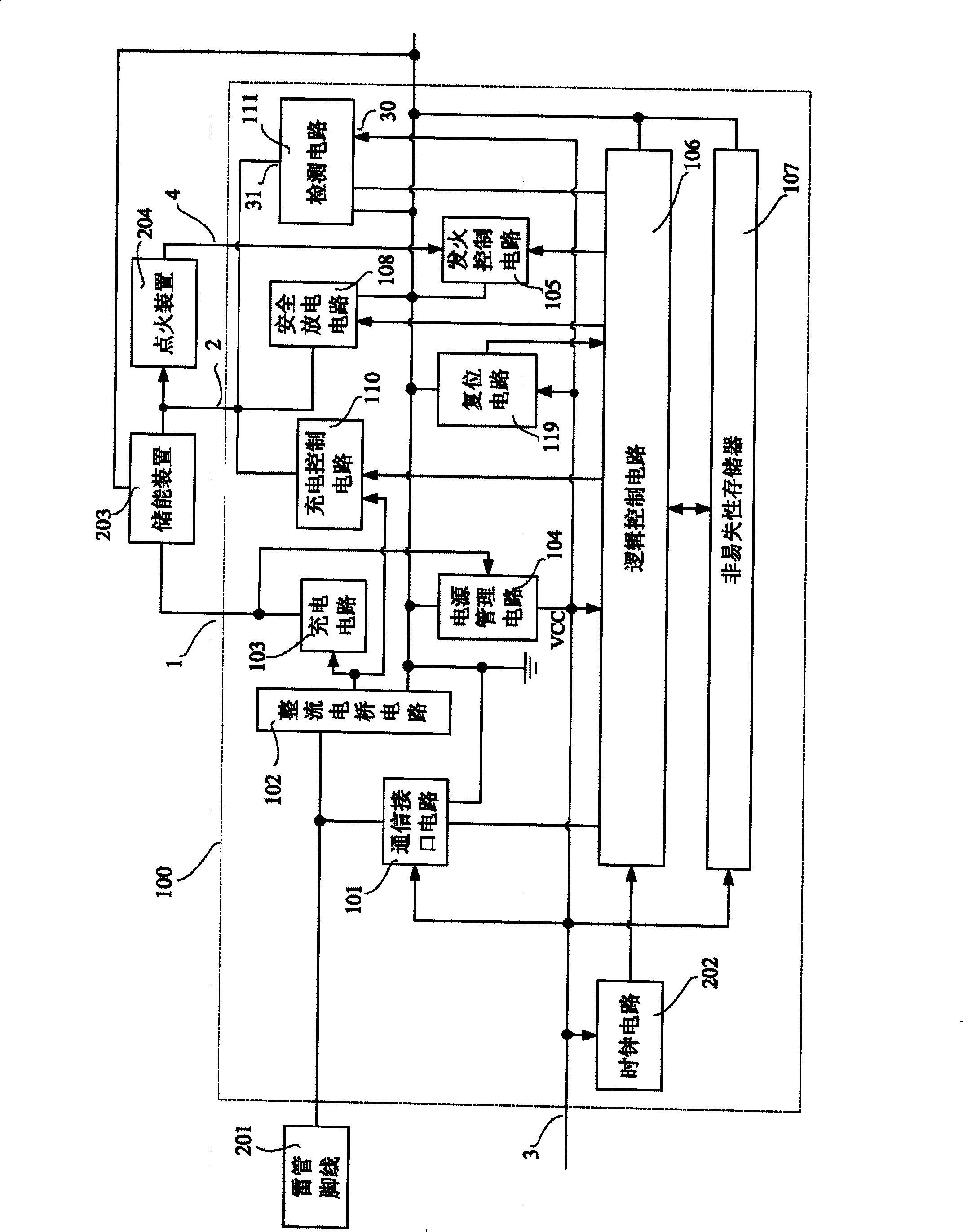

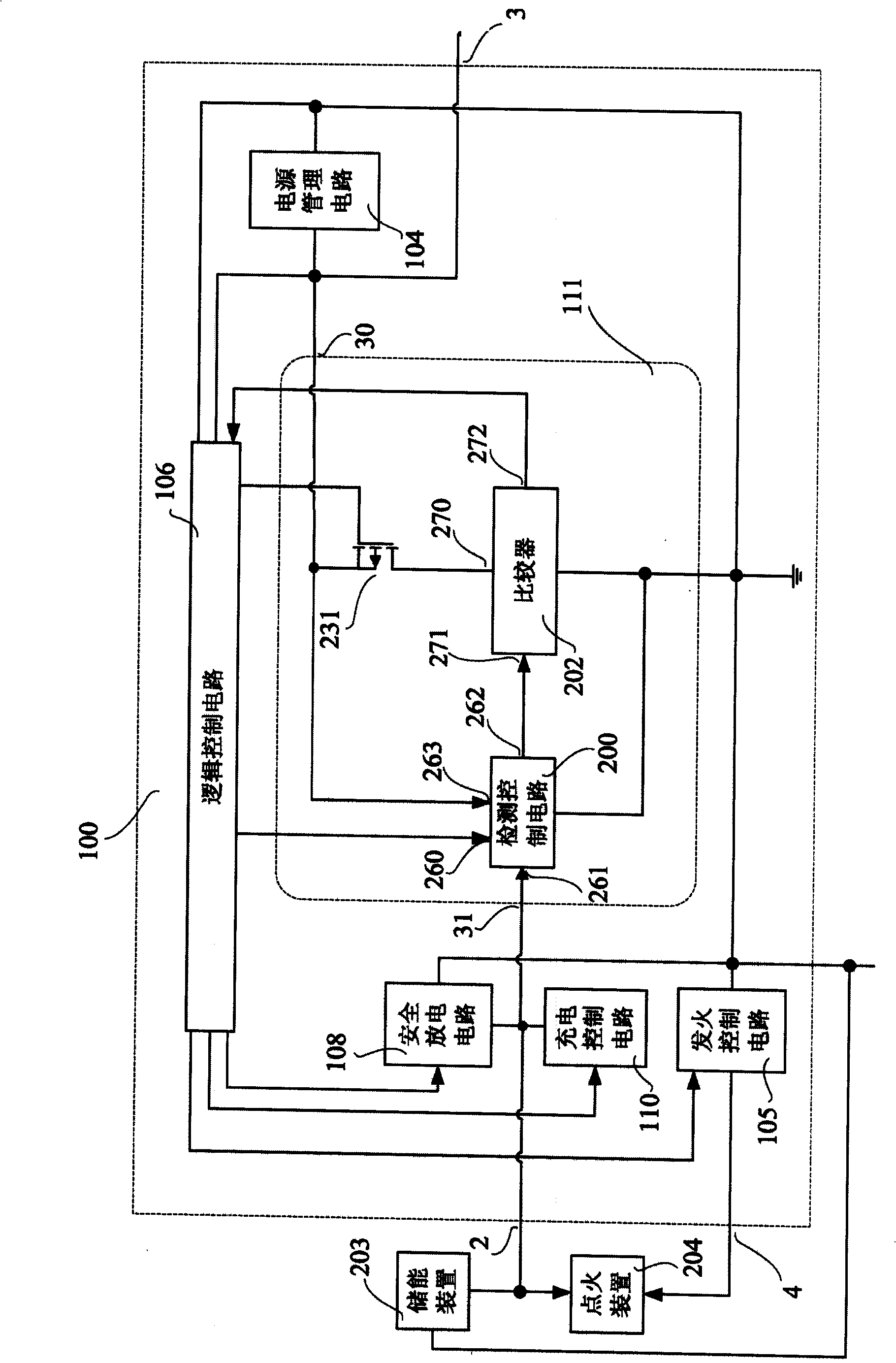

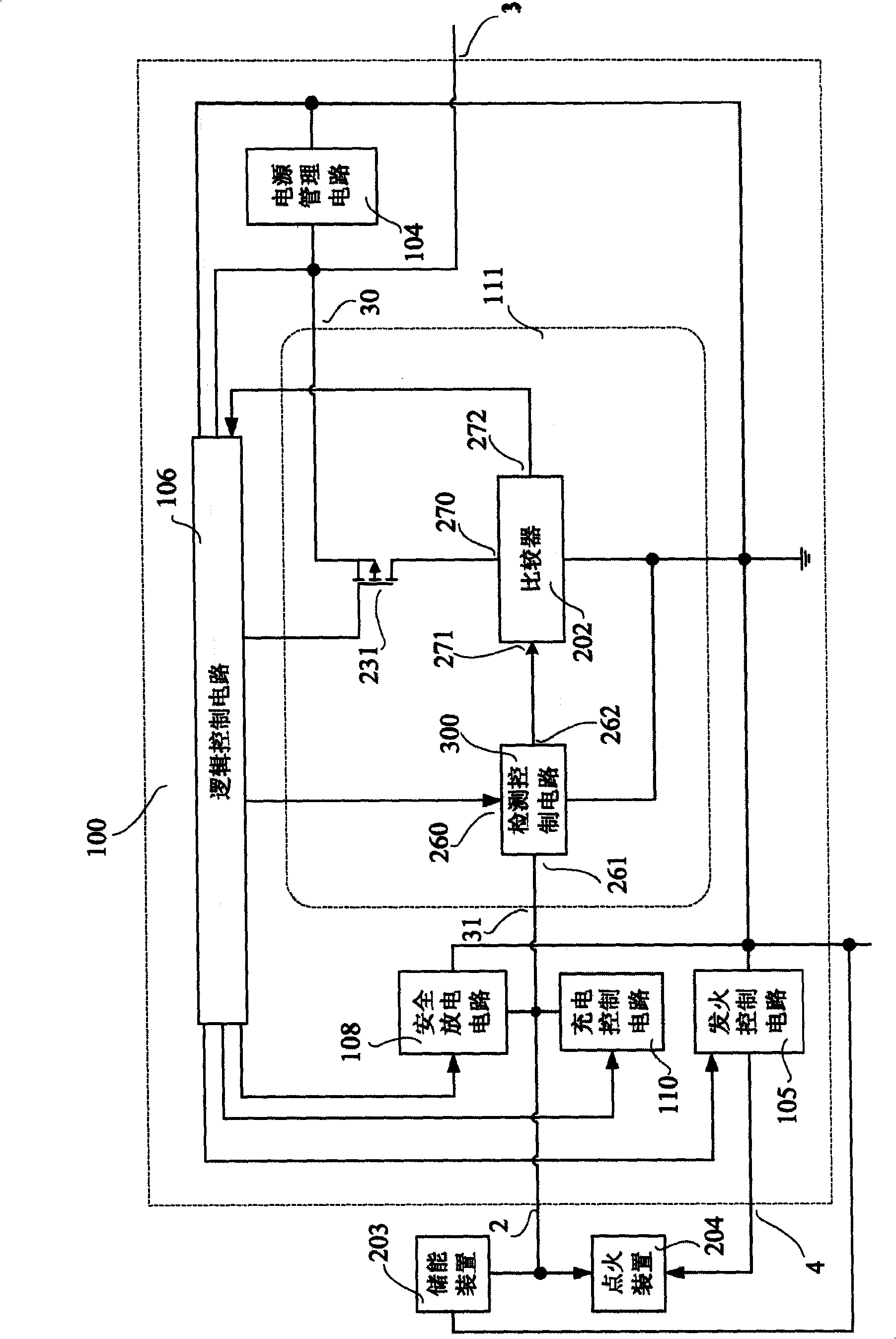

[0069] Such as figure 1 , an electronic detonator control chip 100, comprising a communication interface circuit 101, a rectifier bridge circuit 102, a charging circuit 103, a charging control circuit 110, a power management circuit 104, an ignition control circuit 105, a logic control circuit 106, and a nonvolatile memory 107 , a reset circuit 119 , a safety discharge circuit 108 , and a clock circuit 202 . One end of the charging circuit 103 is connected to the rectifier bridge circuit 102 , the other end is connected to the power management circuit 104 , and the other end is connected to the outside of the chip 100 to form a pin 1 . One end of the charge control circuit 110 is connected to the rectifier bridge circuit 102 , the other end is connected to the logic control circuit 106 , and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com