Double offset parameter circle contour measurement model and biased error separation method

A technology of profile measurement and offset error, applied in measurement devices, instruments, etc., can solve problems such as not being raised and affecting measurement accuracy, and achieve the effect of improving accuracy, avoiding principle defects, and solving principle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

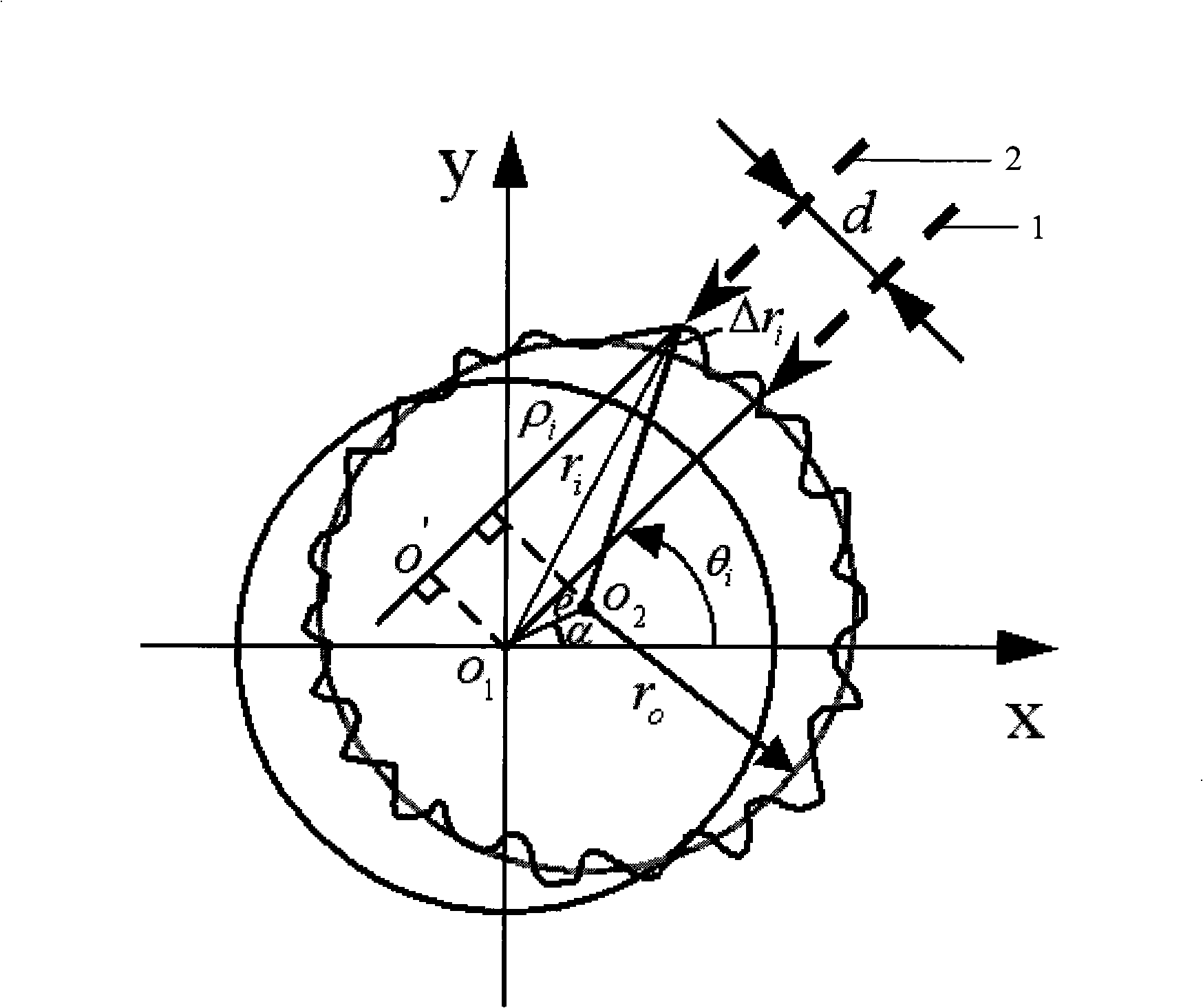

[0035] Such as figure 1 As shown, it is the circular profile measurement model with double offset parameters proposed by the present invention. In addition to the eccentricity error (e, α) of the tested piece introduced in the traditional measurement model, the sensor head offset error d is also introduced in this model, That is, when the sensor measurement direction does not pass the instrument to measure the center of rotation o 1 , but offset d within the measurement section, and the center of the least square circle of the measured section of the tested piece o 2 and measuring the center of gyration o 1 When there is no overlap and the eccentricity of the tested piece is e, the sensor measured is not relative to the measurement center of rotation o 1 The polar radius r i , but with respect to the instantaneous center of measurement o′ and the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com