Heat pump having impulse-width modulation controller

A technology of pulse width modulation and heat pump, which is applied in the direction of reversible cycle compressors, refrigerators, refrigeration components, etc., and can solve the problems that have not yet been introduced into heat pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

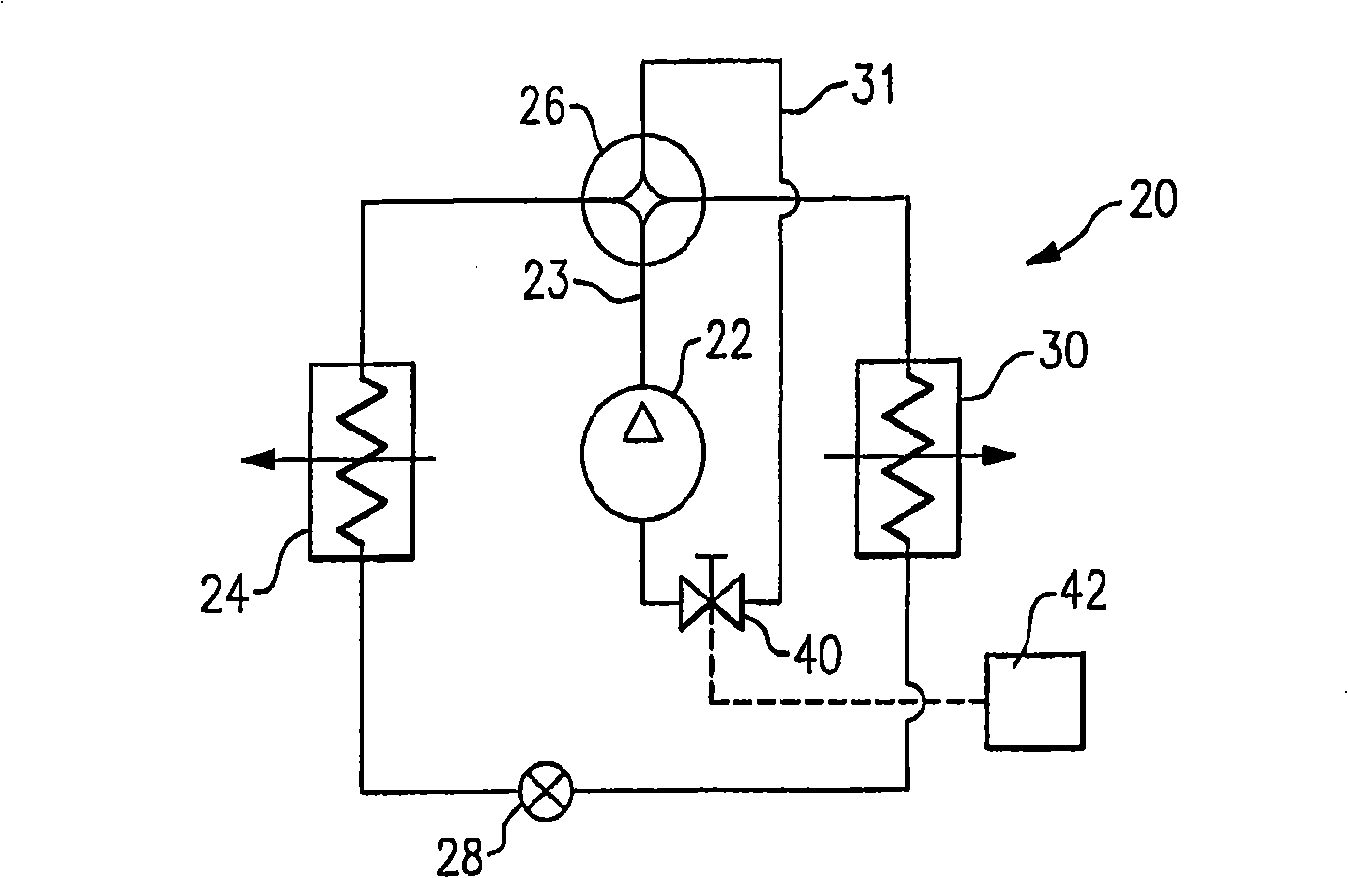

[0019] Figure 1A Shown is a heat pump refrigeration system 20 comprising a compressor 22 having a discharge line 23 supplying compressed refrigerant to a four-way reversing valve 26 . The four-way reversing valve 26 selectively connects the refrigerant from the discharge line 23 to the outdoor heat exchanger 24 when the system operates in the cooling mode, or connects the refrigerant from the discharge line 23 to the outdoor heat exchanger 24 when the system operates in the heating mode. Indoor heat exchanger 30. In either case, the refrigerant passes to the main expansion device 28 from the heat exchanger it first encounters after leaving the compressor. Refrigerant travels from the primary expansion device 28 up to the second heat exchanger and back to the four-way reversing valve 26 . The four-way reversing valve 26 sends the refrigerant along the pipeline to the suction pipeline 31 , and the suction pipeline returns to the compressor 22 . Here is a very simplified schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com