Double-hose holder

A technology for hose clamps and fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, liquid materials, etc., can solve the problems of low production efficiency, low qualification rate, long filling time, etc., and achieve reliable performance, improve production efficiency, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

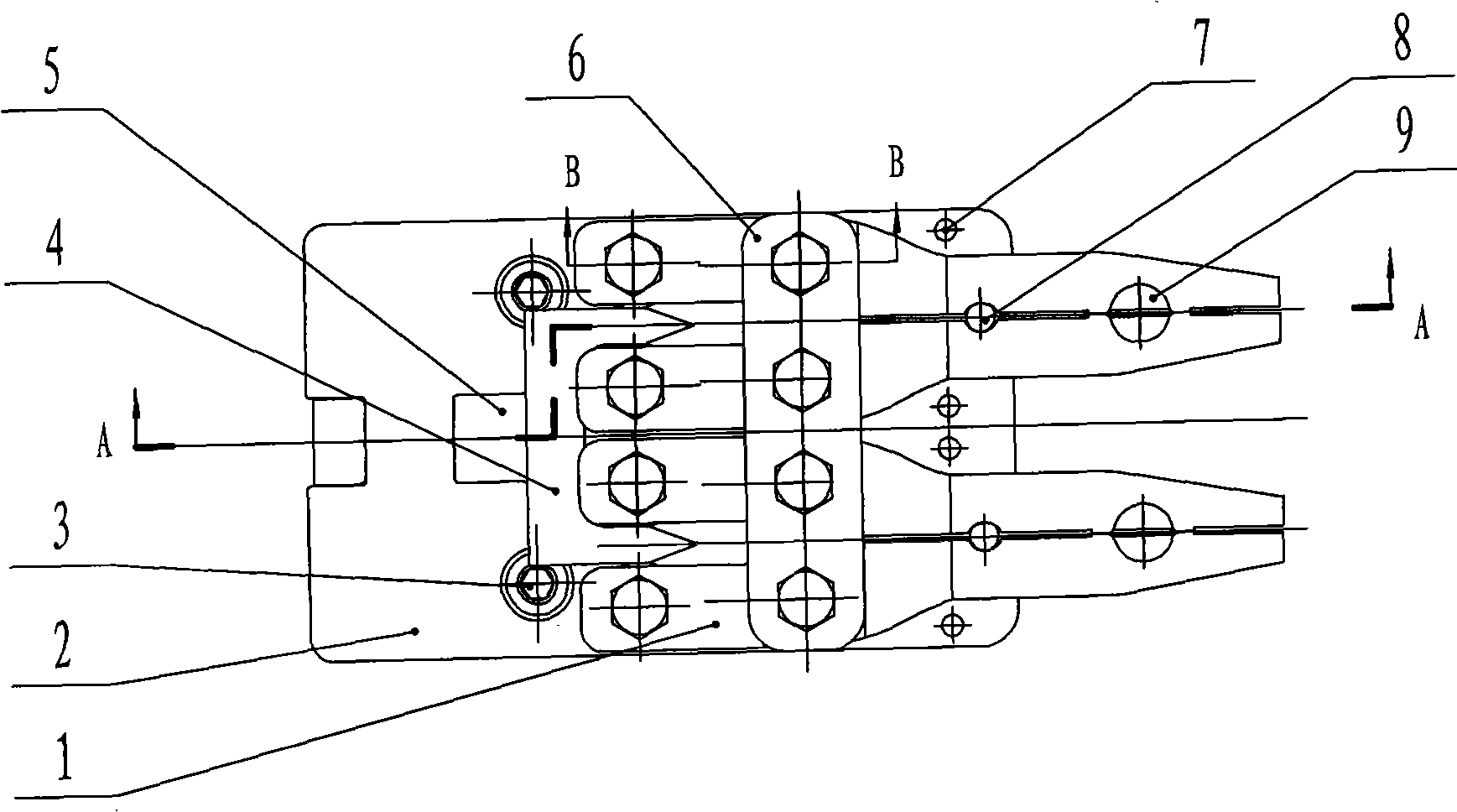

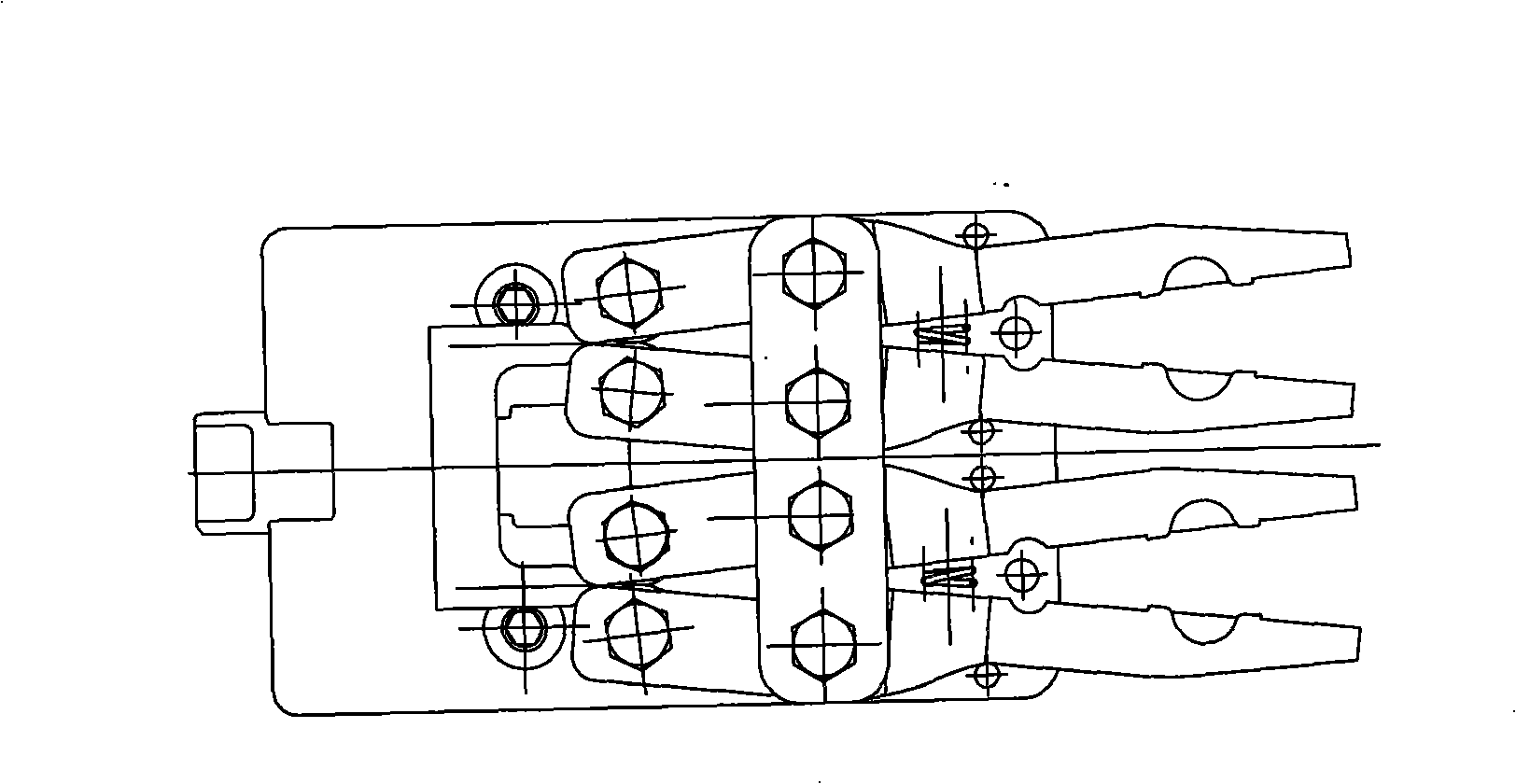

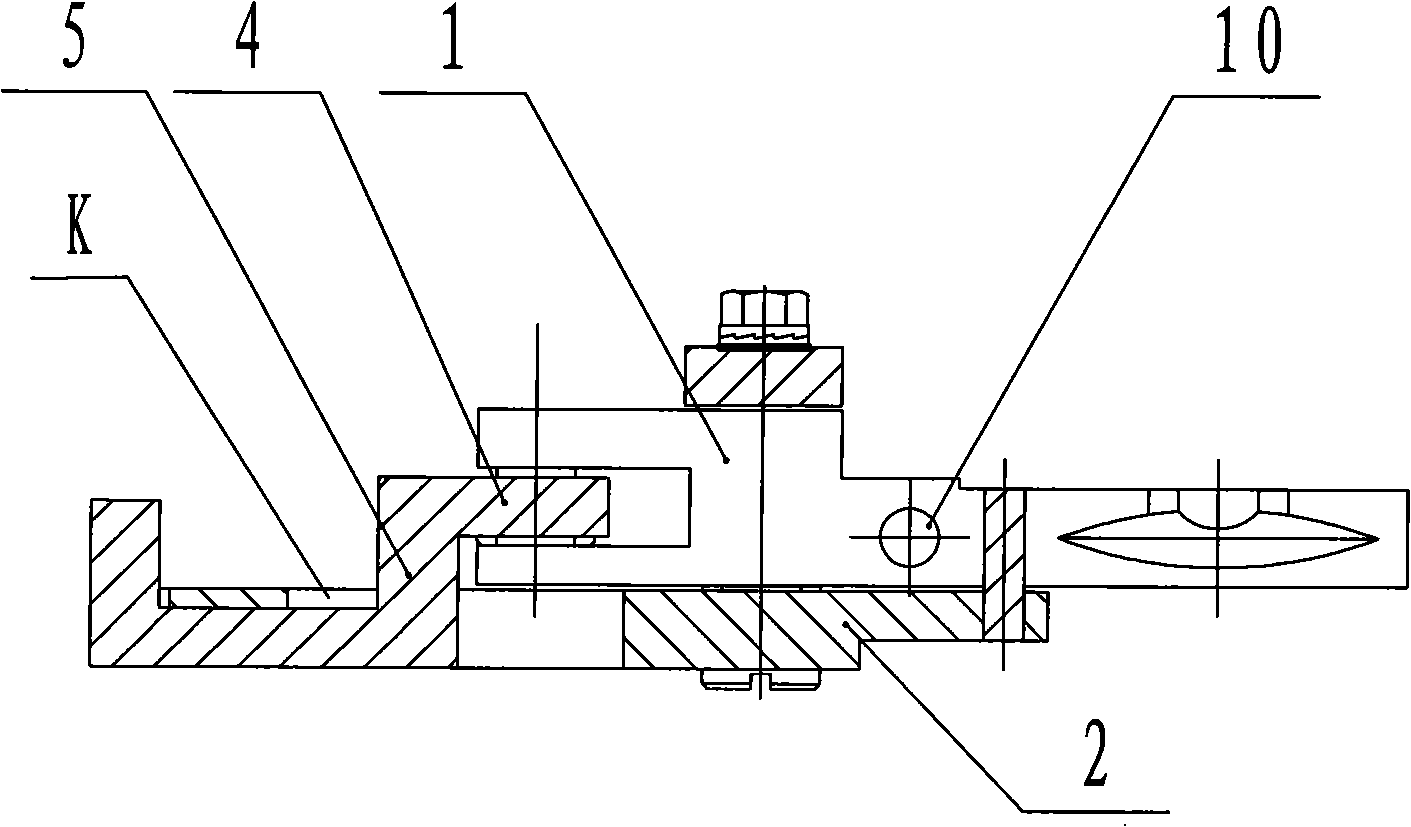

[0019] As shown in the figure, the double hose clamp of the present invention has two sets of clamps, each set of clamps is composed of a pair of opposite grippers, and the front ends of each pair of grippers are provided with corresponding hose clamps 9, and the side-by-side The four grippers 1 of the two sets of grippers are installed on the bottom plate 2 through the gripper pin shaft 11, and the upper ends of the gripper pin shafts are uniformly fixed by the pressure plate 6, and a wedge-shaped push block is arranged between the rear ends of the two grippers of each pair of grippers , the wedge-shaped push blocks of the two sets of fixtures are fixed together, or the wedge-shaped push blocks 4 of U-shaped structure are directly integrated. The U-shaped wedge-shaped push blocks 4 are connected to the push frame 5, and the push frame 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com