Barium titanate based magnetic thin film material and preparation method thereof

A technology of magnetic thin film and thin film material, which is applied in the field of material science and can solve problems such as having no application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

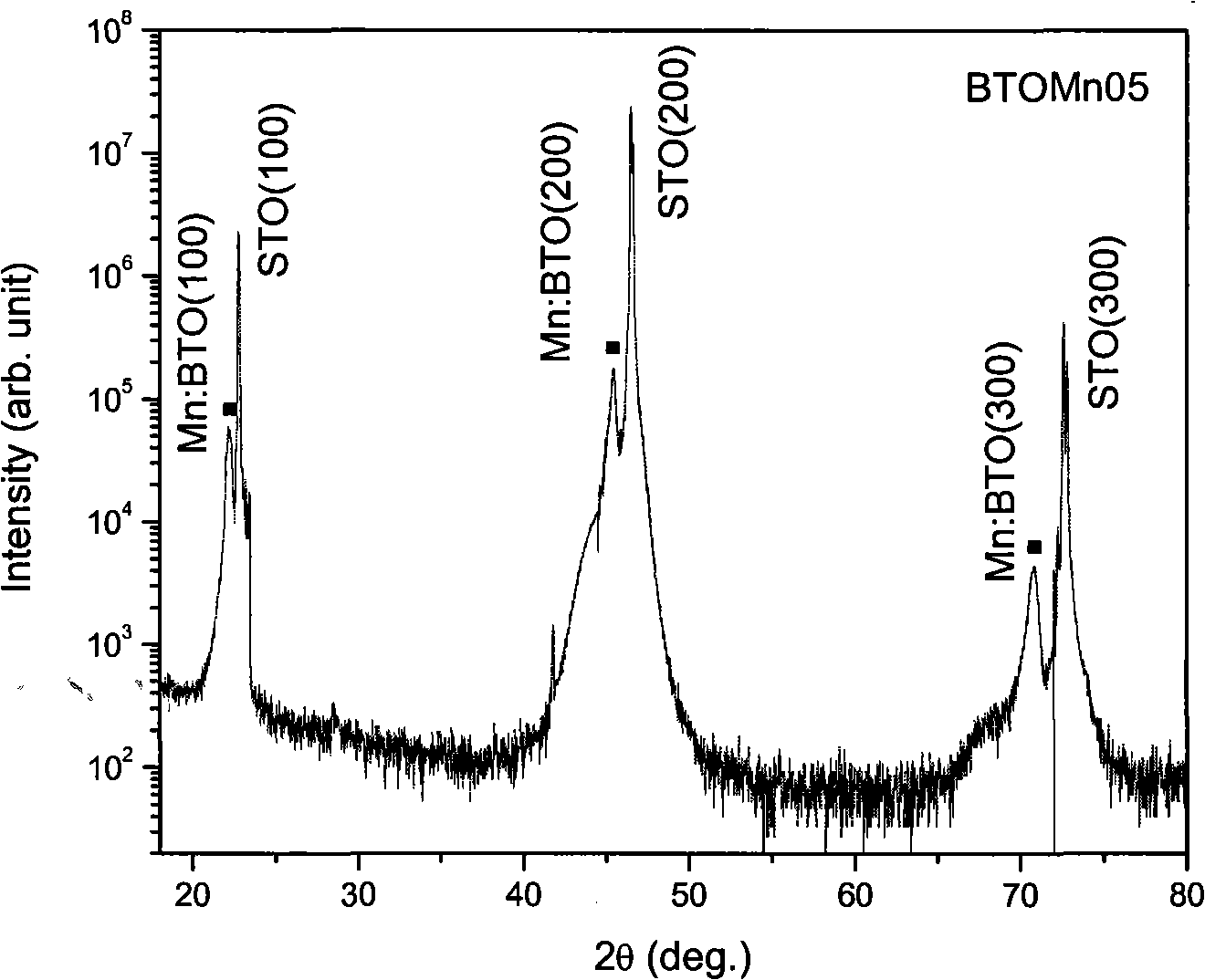

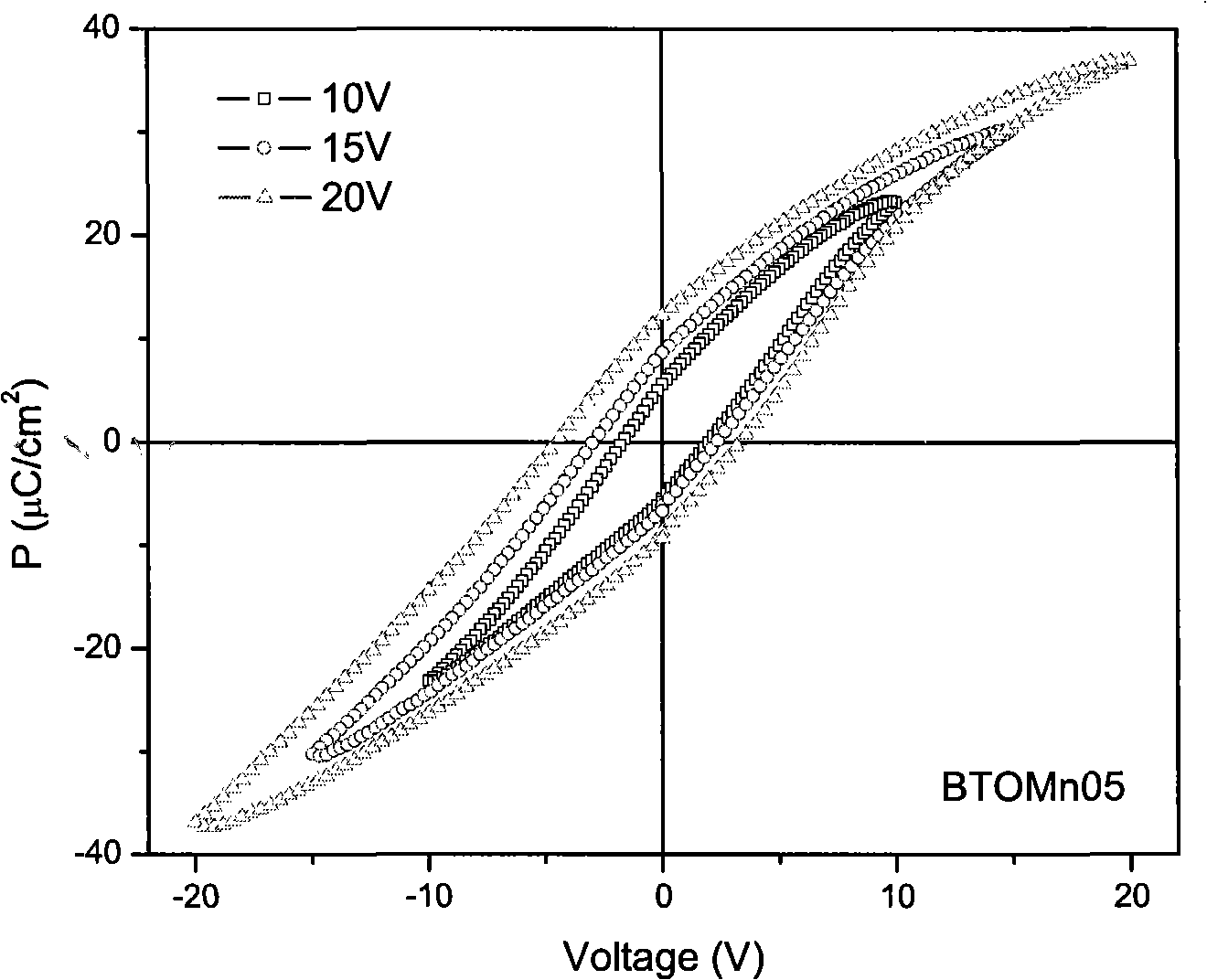

[0032] Example 1: Weigh an appropriate amount of barium carbonate, titanium dioxide, and manganese carbonate powder according to the formula in Table 1, add an appropriate amount of alcohol, take it out after ball milling in a ball mill for 12 hours, and dry the alcohol in an oven at 80°C. Then, put the dried mixed powder into a high-temperature furnace at 1000°C to pre-fire the phase to form BTO powder. Add PVA with a concentration of 1% to the pre-fired powder to granulate, sieve after granulation, press into a disc with a diameter of 20 mm, and sinter at a high temperature of 1300 ° C. The temperature and time process parameters are shown in Table 4. A BTO target with Mn doping amount of 0.5% was obtained.

[0033] After preparing the target, pulsed laser deposition (PLD) was used to deposit the SrTiO 3 Thin films are deposited on the substrate, and the laser is a KrF (λ=248nm) excimer laser. During the deposition process, the laser energy density is kept at 1.5J / cm 2 , t...

Embodiment 2

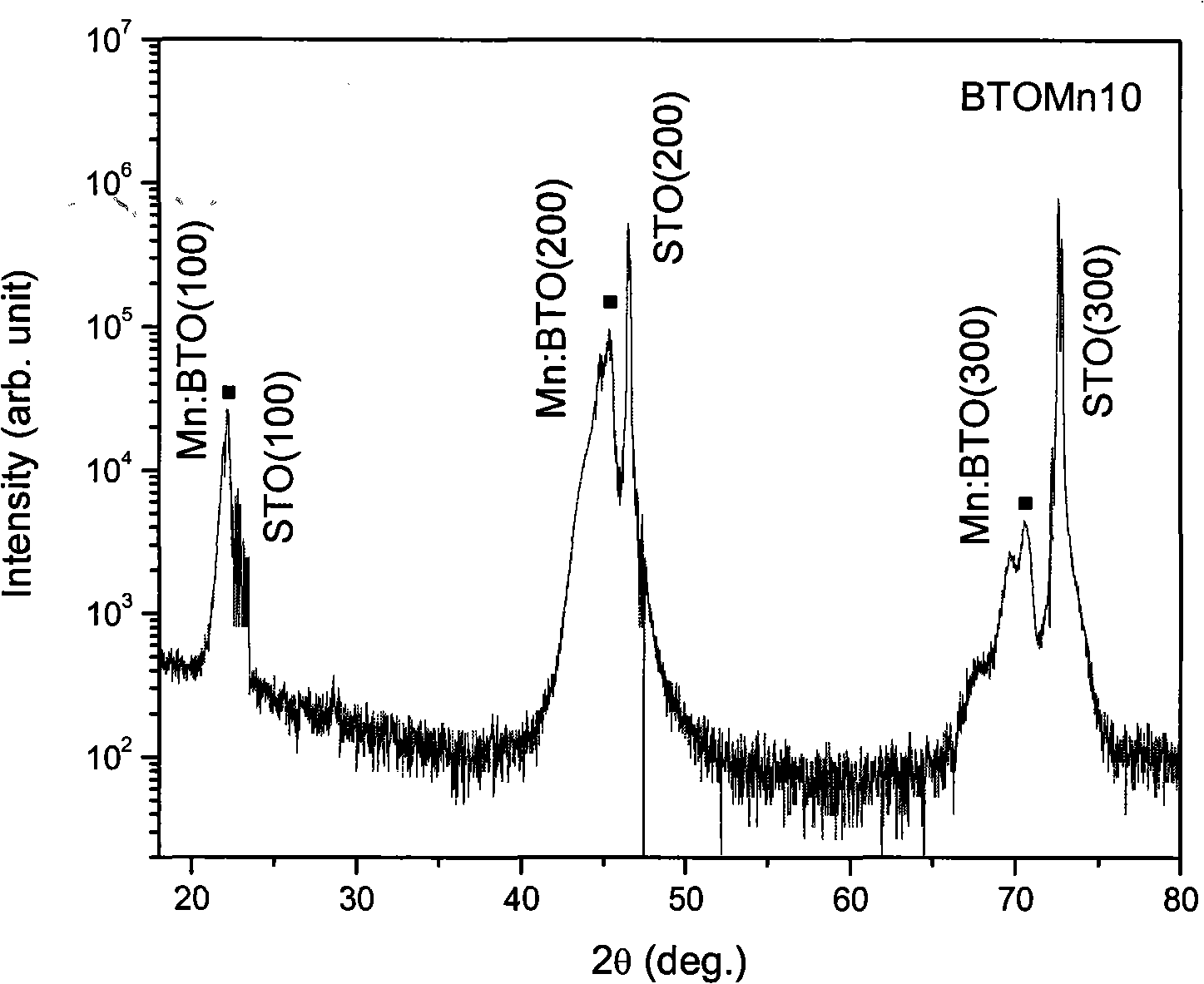

[0034] Example 2: Weigh an appropriate amount of barium carbonate, titanium dioxide, and manganese carbonate powder according to the formula in Table 2, add an appropriate amount of alcohol, ball mill it in a ball mill for 12 hours, take it out, and put it into an oven at 80°C to dry the alcohol. Then, put the dried mixed powder into a high-temperature furnace at 1000°C to pre-fire the phase to form BTO powder. Add PVA with a concentration of 1% to the pre-fired powder to granulate, sieve after granulation, press into a disc with a diameter of 20 mm, and sinter at a high temperature of 1300 ° C. The temperature and time process parameters are shown in Table 4. A BTO target with Mn doping amount of 1.0% was obtained.

[0035] After preparing the target, pulsed laser deposition (PLD) was used to deposit the SrTiO 3 Thin films are deposited on the substrate, and the laser is a KrF (λ=248nm) excimer laser. During the deposition process, the laser energy density is kept at 1.5J / cm...

Embodiment 3

[0036] Example 3: Weigh an appropriate amount of barium carbonate, titanium dioxide, and manganese carbonate powder according to the formula in Table 1, add an appropriate amount of alcohol, ball mill in a ball mill for 12 hours, take it out, and put it into an oven at 80°C to dry the alcohol. Then, put the dried mixed powder into a high-temperature furnace at 1000°C to pre-fire the phase to form BTO powder. Add PVA with a concentration of 1% to the pre-fired powder to granulate, sieve after granulation, press into a disc with a diameter of 20 mm, and sinter at a high temperature of 1300 ° C. The temperature and time process parameters are shown in Table 4. A BTO target with Mn doping amount of 3.0% was obtained.

[0037] After preparing the target, pulsed laser deposition (PLD) was used to deposit the SrTiO 3 Thin films are deposited on the substrate, and the laser is a KrF (λ=248nm) excimer laser. During the deposition process, the laser energy density is kept at 1.5J / cm 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap