Polymer electric heating membrane and use thereof

A polymer conductive and polymer technology, which is applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of short service life, low safety, and low thermal efficiency, and achieve long service life, high safety, and thermal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

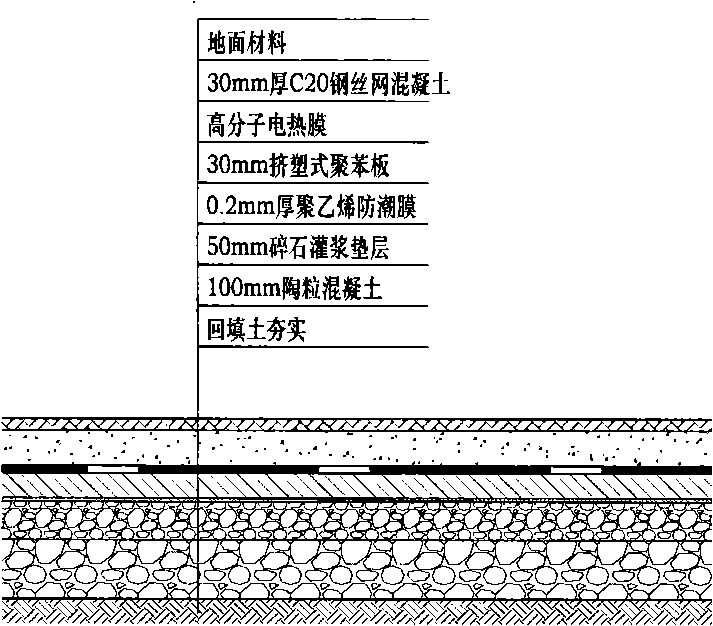

[0030] Specific embodiment one, heat treatment is carried out to the ground of the first floor:

[0031] like image 3 As shown, when the construction project is handed over, the ground is generally compacted with backfill soil, ceramsite concrete layer, gravel grouting layer, and moisture-proof treatment.

[0032] When performing heating treatment, first lay a layer of 30mm thick extruded polystyrene board on the ground as the insulation layer; then lay the polymer electric heating film of the present invention; then lay a layer of 30mm thick C20 steel wire mesh concrete as the structure layer, and apply ground material on the structural layer.

[0033] like Figure 4 As shown, when the ground of the first floor is decorated with wooden floors, the composite floor can be directly laid on the polymer electric heating film.

specific Embodiment 2

[0034] Specific embodiment two, carry out heating treatment to the ground above the second floor and the second floor:

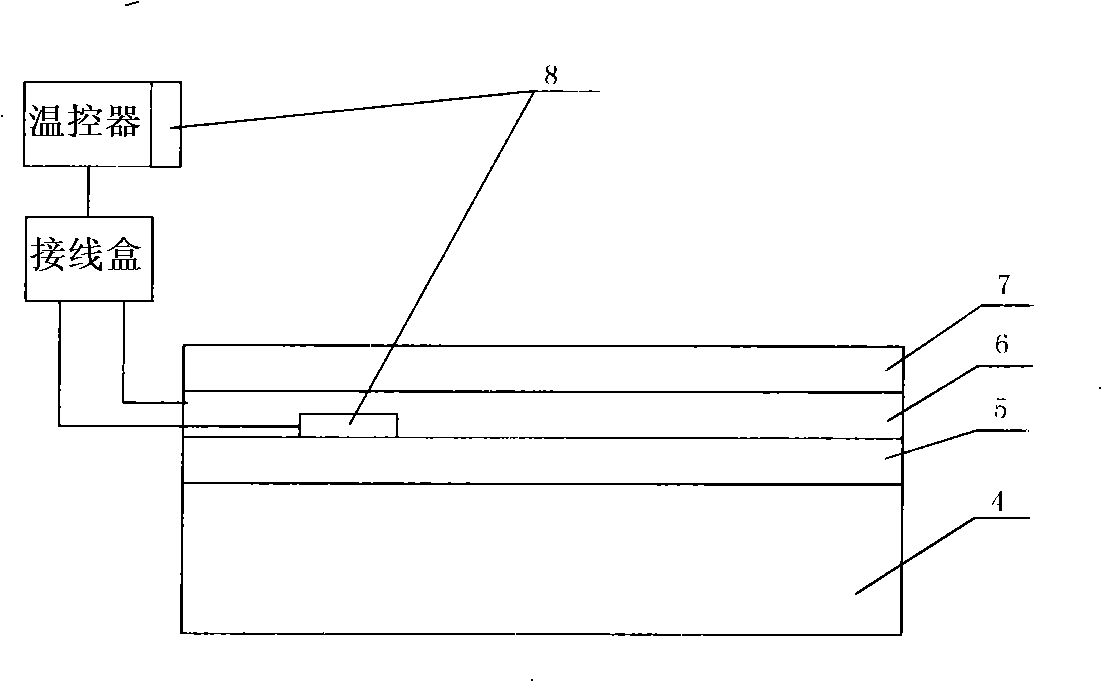

[0035] like Figure 5 , Image 6 As shown, when performing heating treatment, first lay a layer of 20mm thick extruded polystyrene board as the insulation layer on the floor; then lay the polymer electric heating film of the present invention; then lay the concrete structure layer or composite floor.

[0036] When heating the ground above the second floor and above, the thickness of the insulation layer can be slightly thinner than that of the first floor.

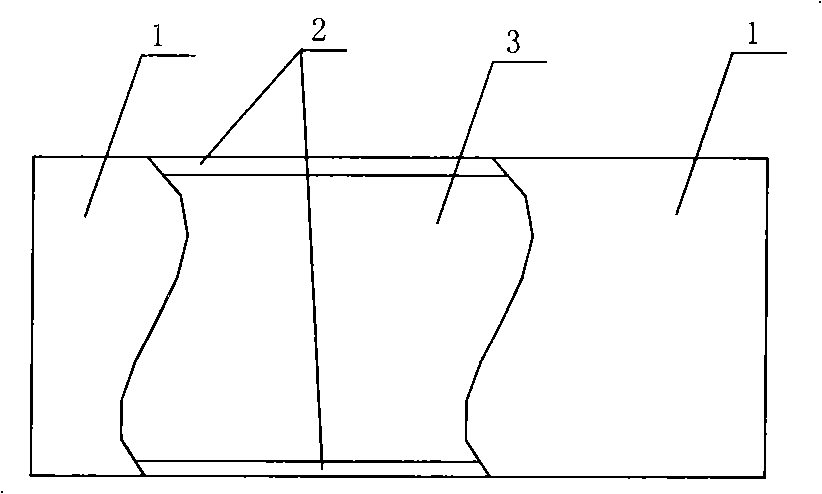

[0037] The polymer electric heating film of the present invention is formed by uniformly coating the polymer conductive paint synthesized by bridging and selective grafting technology on the base material provided with electrodes in advance, and undergoing insulation treatment. It has "arbitrary width and shape" and "arbitrary work The characteristics of "voltage (AC, DC)" and "arbitrary power per unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com