High Mn steel sheet for high corrosion resistance and method of manufacturing galvanizing the steel sheet

A high-corrosion-resistant steel plate technology, applied in chemical instruments and methods, hot-dip plating process, coating, etc., can solve research problems and achieve excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0089] Hereinafter, the present invention is described in detail with reference to examples.

Embodiment

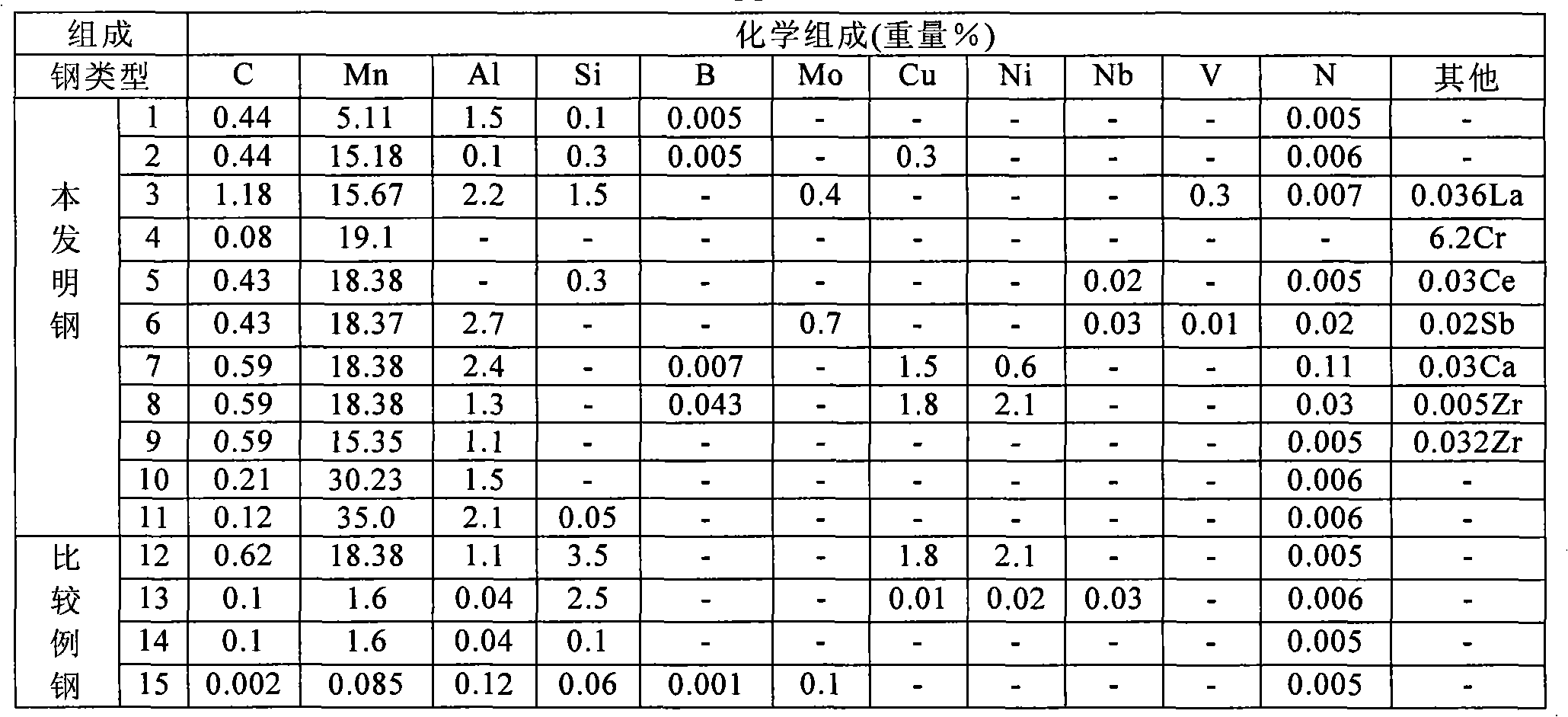

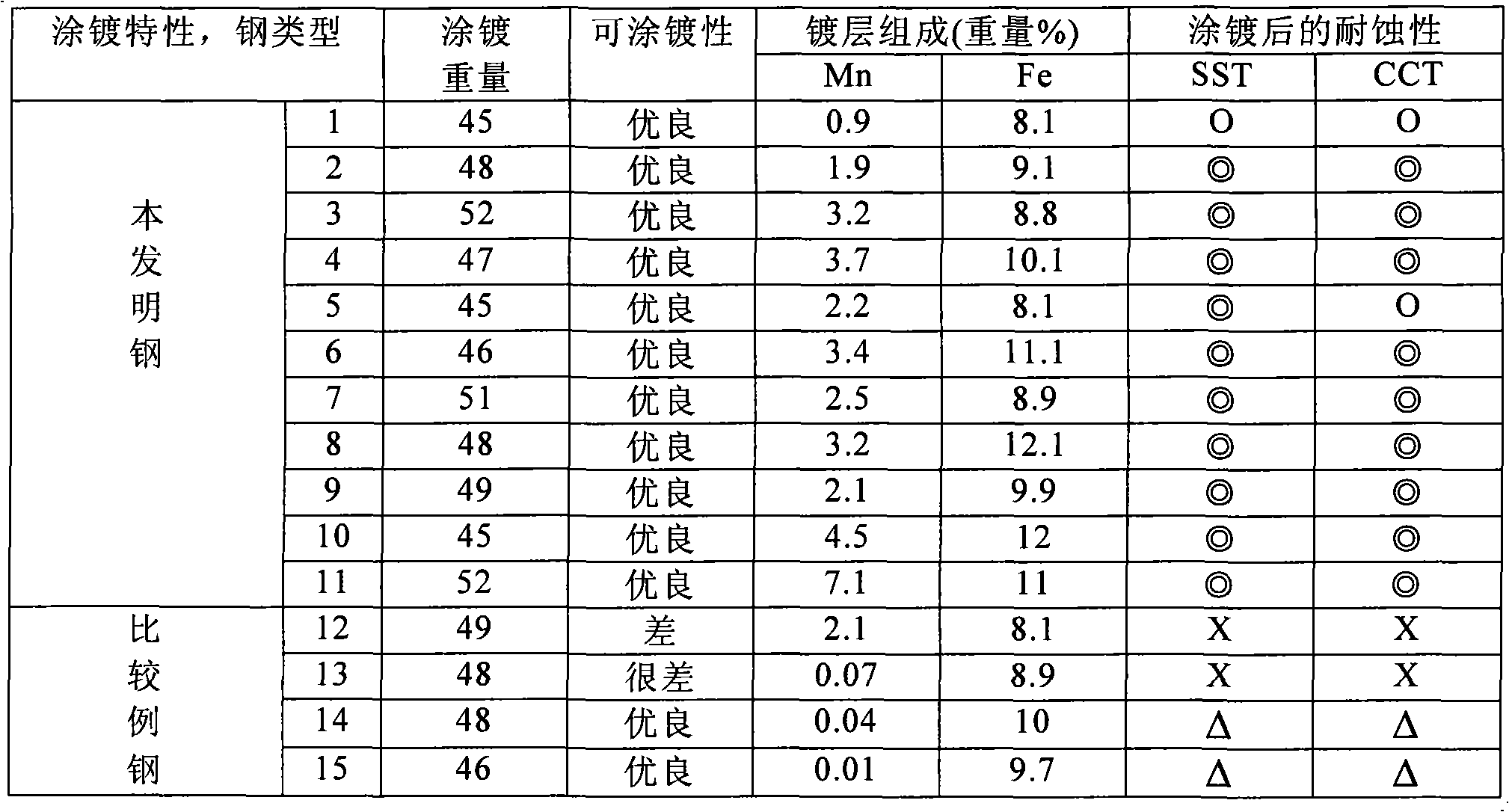

[0091] A plurality of billets having the compositions shown in Table 1 below were produced.

[0092] In Table 1, No. 1 to No. 11 steels are steels of the present invention, and have the element content ranges according to the present invention, while No. 12 to No. 15 steels are comparative steels, and do not have the element content ranges according to the present invention .

[0093]The billet is heated to a temperature of 1200° C., enabling hot rolling of the billet. Hot finish rolling of billet. The billets were coiled at 620°C and air cooled. HCl solution was used to remove oxides on the surface of each steel plate. The steel sheets were cold rolled at a reduction ratio of 70%. As a result, a cold-rolled steel sheet was obtained.

[0094] Subsequently, at N 2 -10%H 2 In the atmosphere, the cold-rolled steel sheet was annealed at 620-880°C for 90 seconds, and placed in a Zn-0.013% Al bath maintained at 460°C. As a result, a hot-dip galvanized layer was formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com