Processing system for large moisture rouging, degreasing, recycling oil and water, and reusing the same

A treatment system and water recovery technology, applied in the field of treatment systems, can solve the problems of inability to solve oil-water emulsification, small separation effect processing capacity, and high water content in the extracted oil, and achieve the effects of avoiding oil-water emulsification, simple equipment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

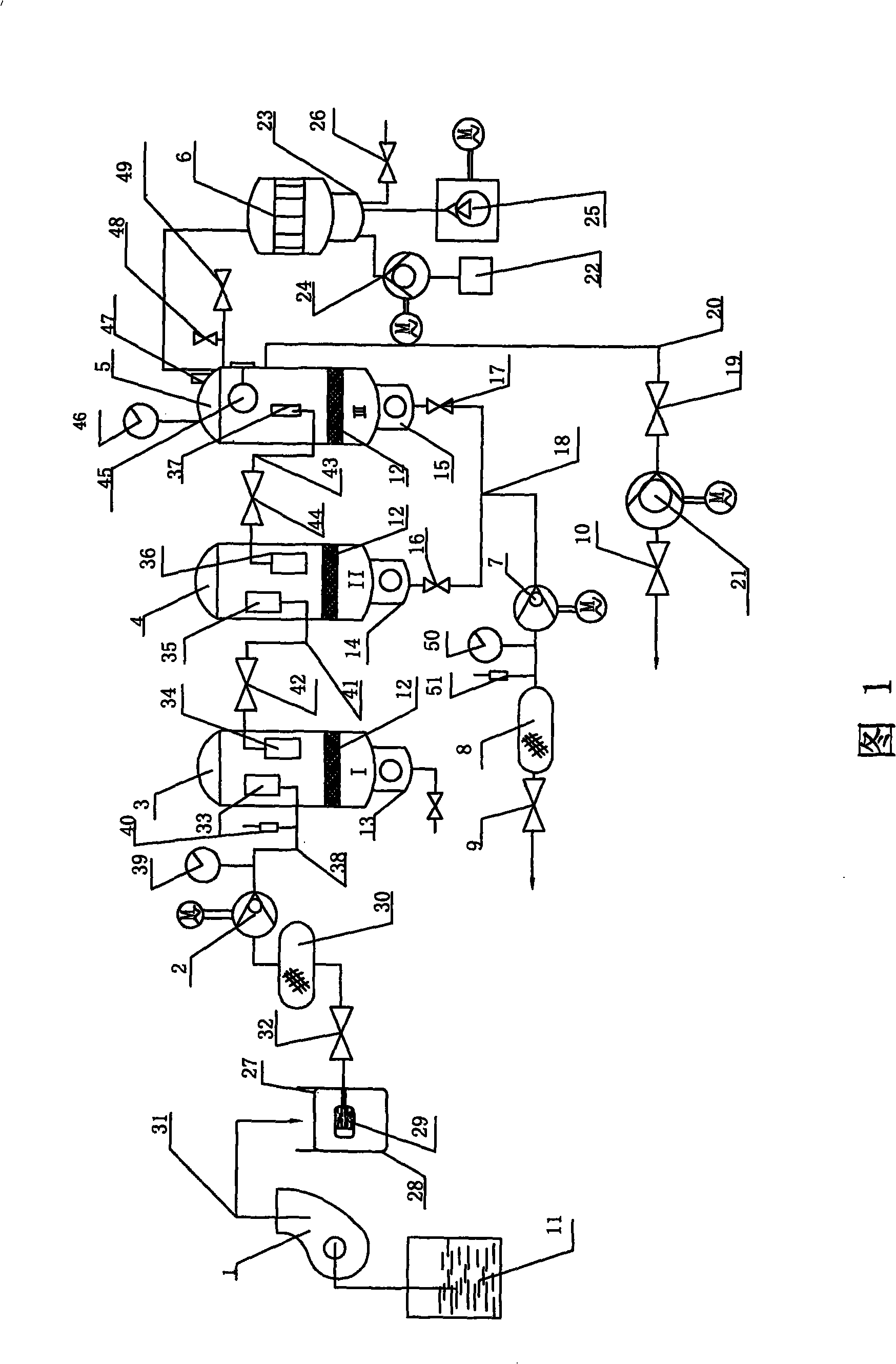

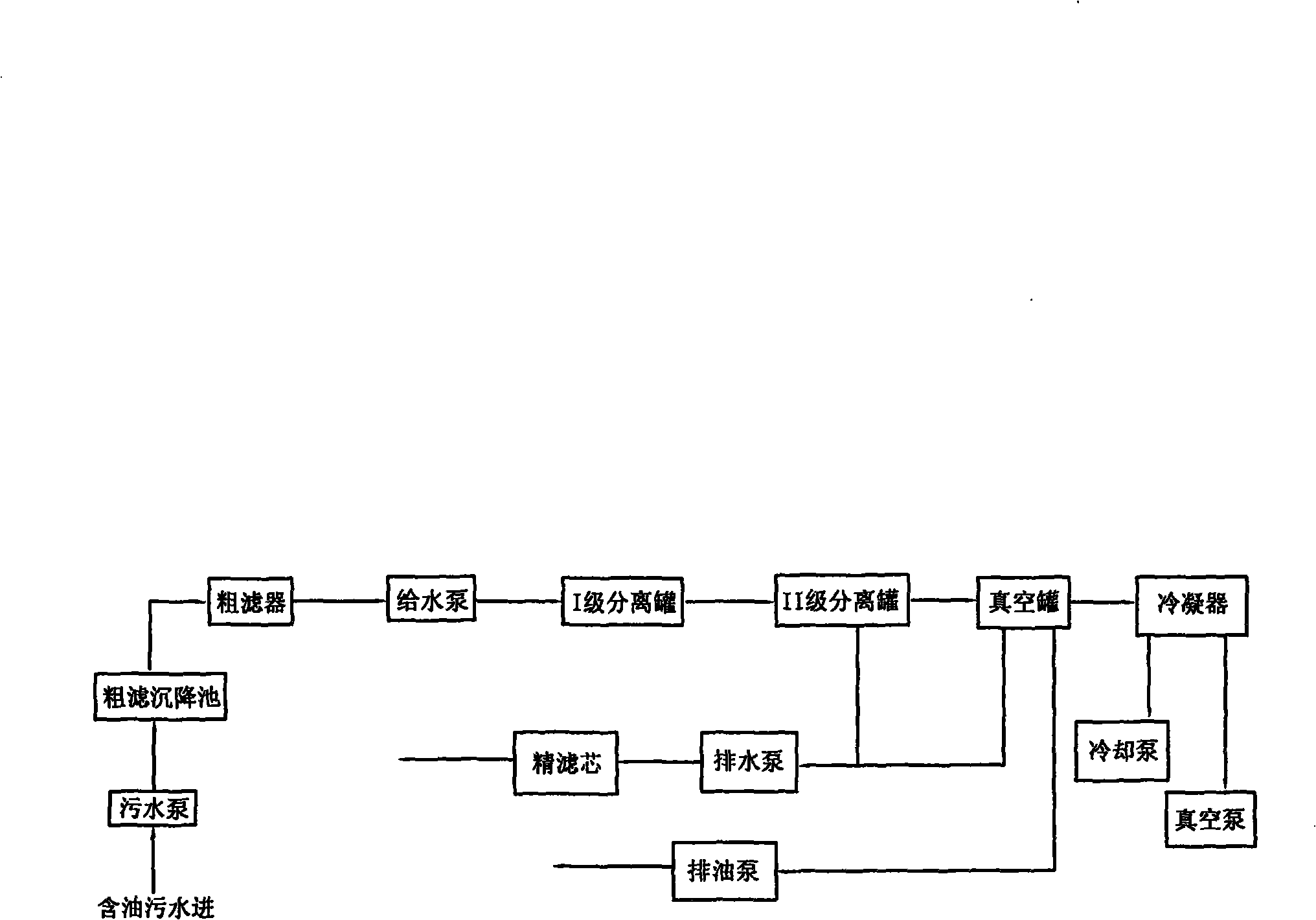

[0010] In Fig. 1, the present invention provides a treatment system for removing impurities from large amounts of water, removing oil and reusing oil and water, which includes a sewage pump 1, a pre-stage coarse filter device, a feed water pump 2, and a first-stage separation tank 3 , Class II separation tank 4, vacuum tank 5, condenser 6, drain pump 7, fine filter 8, water outlet check valve I9, oil drain pump 21, oil drain check valve 10 and oil drain ball valve 19, input of sewage pump 1 end into the sewage pool 11, the sewage pump 1 is connected with the pre-stage coarse filter device, feed water pump 2, I-level separation tank 3, II-level separation tank 4, vacuum tank 5, and condenser 6 in turn, and the I-level separation tank 3 , II-level separation tank 4, vacuum tank 5 are respectively provided with isolation filter screen 12, isolation filter screen 12 is positioned at the lower part of I-level separation tank 3, II-level separation tank 4, vacuum tank 5, and I-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com