Flexible type display panel and manufacturing method thereof, photo-electric device and manufacture method thereof

A technology for a display panel and a manufacturing method, which is applied in the directions of identification devices, optics, nonlinear optics, etc., can solve the problems of easy cracking, insufficient compressive strength of glass substrates, affecting the popularity of displays, etc., and achieves deformation tolerance, light and thin appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

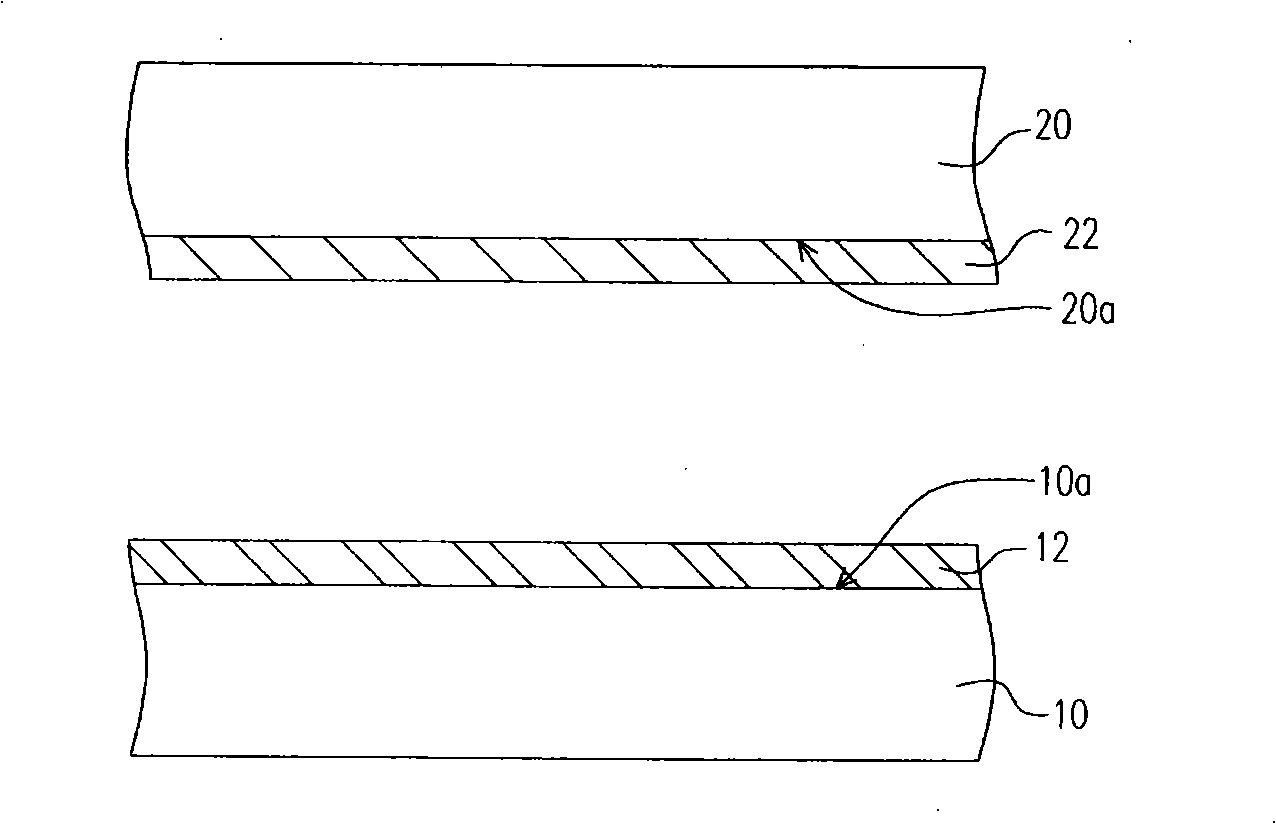

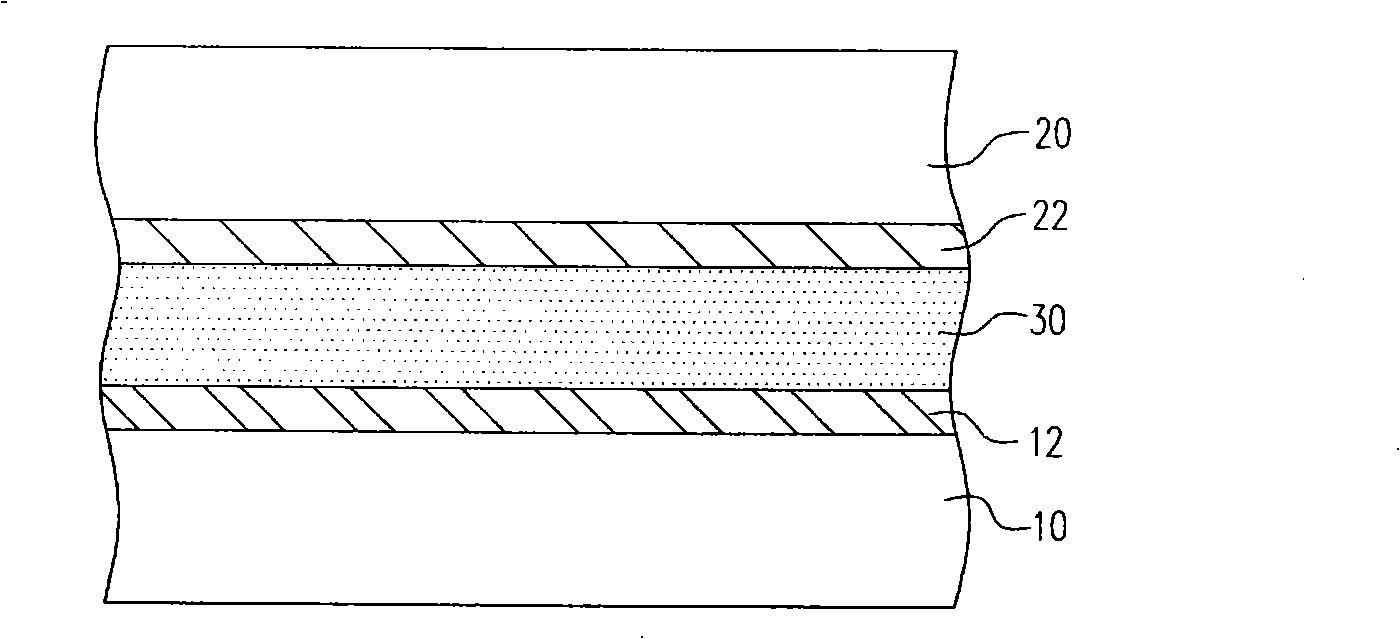

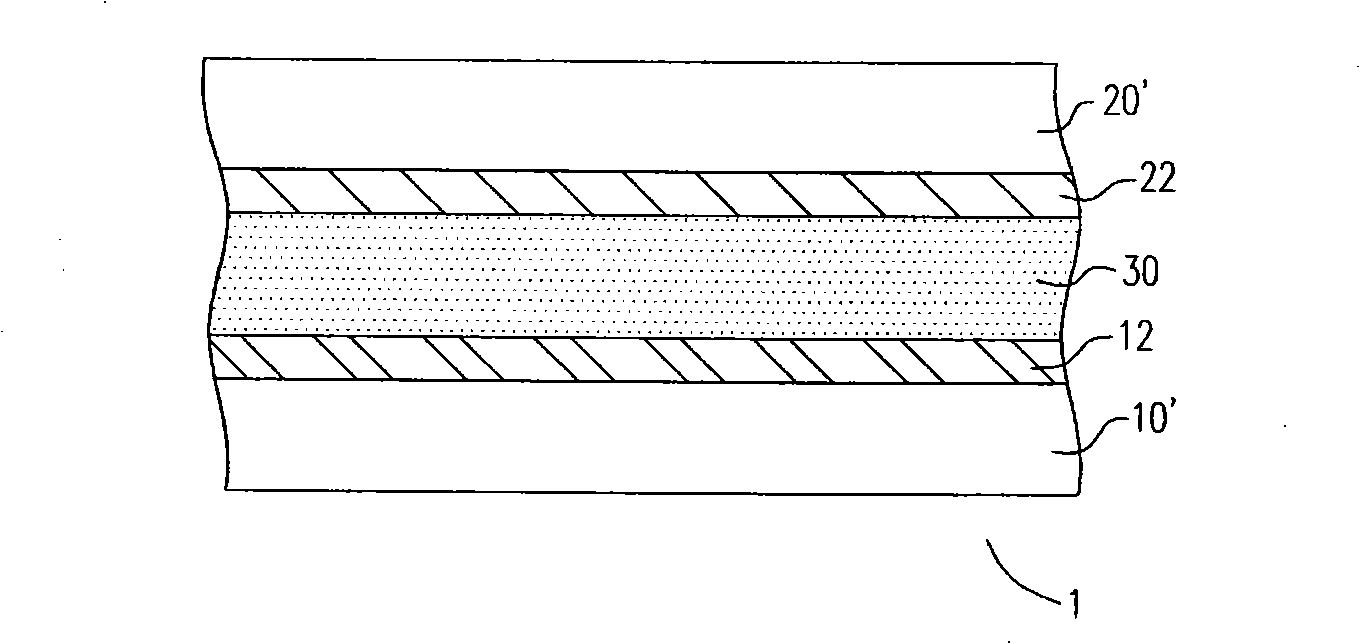

[0049] figure 2 It is a schematic cross-sectional view of a flexible display panel according to an embodiment of the present invention. Please refer to figure 2 , in this embodiment, the flexible display panel 100 includes a first flexible substrate 110, a second flexible substrate 120 and a display medium 130, wherein the display medium 130 is located on the first flexible substrate between the material 110 and the second flexible substrate 120 .

[0050] In detail, a first etch stop layer 112 and an active layer 114 are disposed on the first flexible substrate 110 . A second etch stop layer 122 and a cover layer 124 are disposed on the second flexible substrate 120 . In particular, the first etch stop layer 112 is located between the active layer 114 and the first flexible substrate 110 , and the second etch stop layer 122 is located between the cover layer 124 and the second flexible substrate 120 . In addition, the display medium 130 is located between the active lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com