Explosion-proof permanent-magnet brushless DC motor

A DC motor, permanent magnet brushless technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of reduced output power and efficiency, inability to run at high speed, cumbersome work procedures, etc., to solve the problems of heat and loss, The effect of improving power density and flexible control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

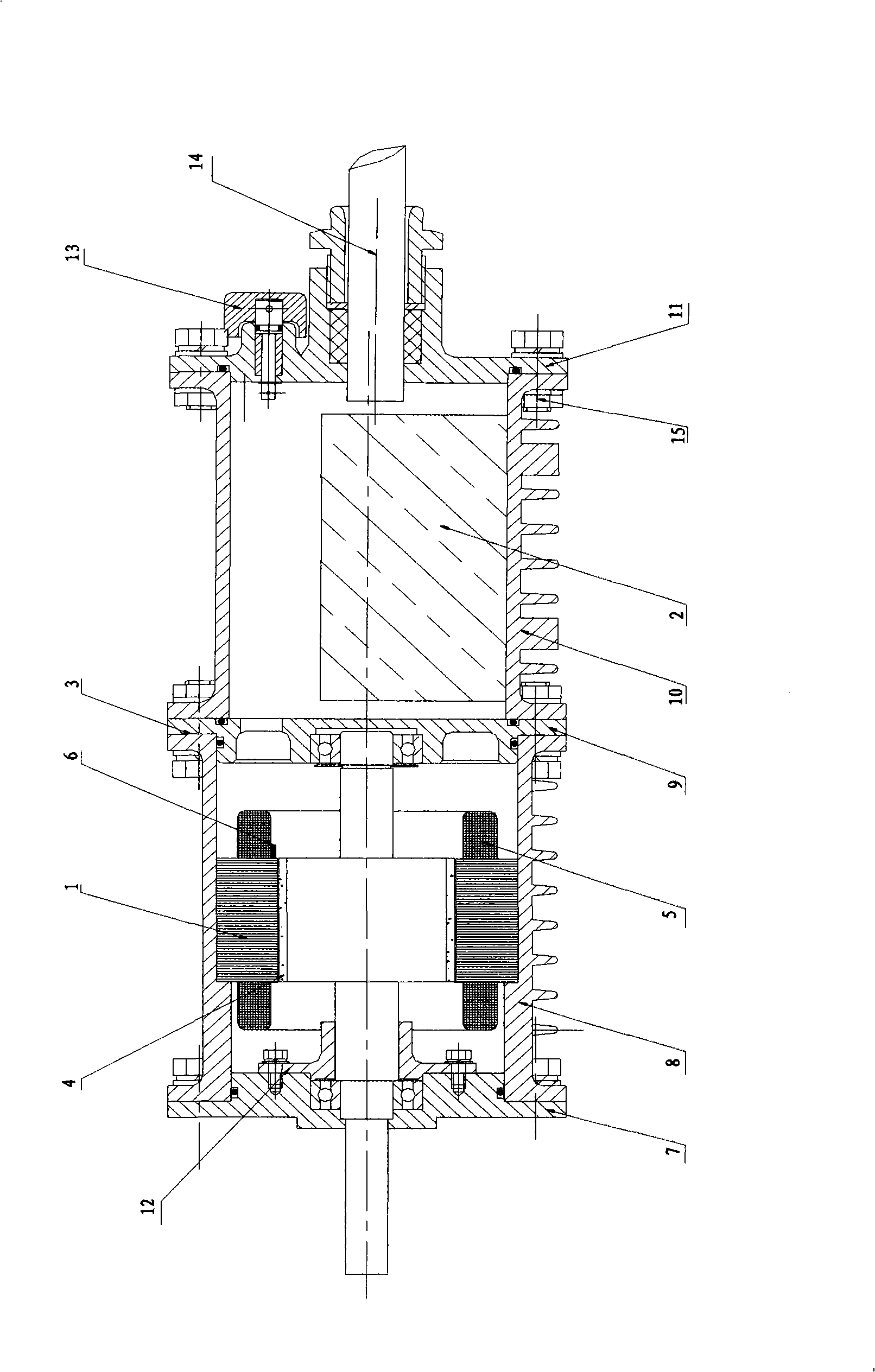

[0013] As shown in the drawings, the motor body 1 is a permanent magnet brushless DC motor, and the rotor magnet 4 of the motor body 1 is made of rare earth NdFeB permanent magnet material to generate the rotor magnetic field; the end of the stator winding 5 is equipped with three rotor magnets. The steel position sensor 6 is used to detect the position of the rotor magnet 4, the rotor magnet position sensor 6 is connected with the motor controller 2, and the commutation is realized through the motor controller 2. The motor body 1 and the motor controller 2 have an explosion-proof casing 3: the explosion-proof casing 3 includes the motor front cover 7, the motor casing 8, the motor rear cover 9, the control box 10, the control box cover 11, the rotor explosion-proof sleeve 12, and the switch operation part 13 And cable entry device 14. Motor front cover 7, motor casing 8, motor back cover 9, control box 10, control box cover 11 are connected into a whole by fastening screw 15,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap