Diffusion welding method of TiAl/Nb based alloy and Ni based high-temperature alloy

A high-temperature alloy and diffusion welding technology, which is applied in the direction of welding/welding/cutting items, welding equipment, metal processing equipment, etc., can solve the problems of high cost, complicated process and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

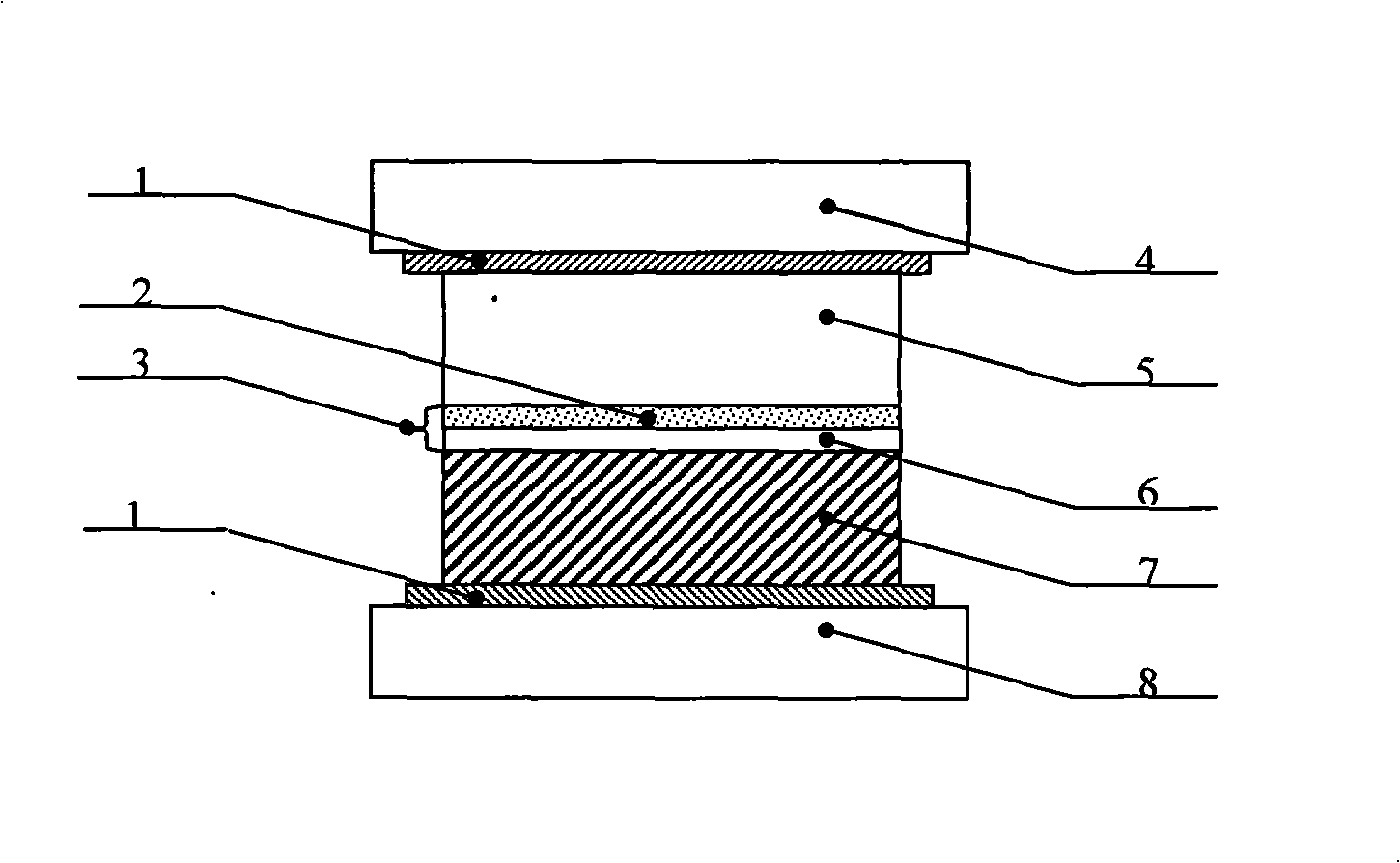

[0016] Example 1: Diffusion welding of TiAl / Nb alloy TiAl and Ni-based superalloy GH710.

[0017] Take a Nb foil with a thickness of 10 μm and a purity of 99.9wt.% and a Ni foil with a thickness of 10 μm and a purity of 99.9wt.%, put them in acetone, clean them ultrasonically for 10 seconds, and dry them in air. Use 1500 # SiC sandpaper is used to grind the surface of TiAl alloy and GH710 superalloy to be welded so that the surface roughness Ra value is less than 1.6. Then put the TiAl alloy and GH710 superalloy into acetone solution, ultrasonically clean them for 5 minutes, and dry them in air. The above-mentioned materials are clamped: the intermediate layer 3 composed of Nb foil 2 and Ni foil 6 is placed between the TiAl / Nb alloy 5-TiAl and the Ni-based superalloy 7-GH710, wherein the Nb foil 2 is in contact with TiAl, Ni foil 6 is in contact with GH710 to build the workpiece to be welded. Put the workpiece to be welded into a vacuum furnace, and place it between the upp...

Embodiment 2

[0019] Example 2: TiAl / Nb alloy Ti 3 Diffusion welding of Al and Ni-based superalloy GH4133.

[0020] Take a Nb foil with a thickness of 15 μm and a purity of 99.9wt.% and a Ni foil with a thickness of 15 μm and a purity of 99.9wt.%, put them in acetone, clean them ultrasonically for 15 seconds, and dry them in air. Use 1500 # SiC sandpaper on Ti 3 The surface of Al alloy and GH710 superalloy to be welded is ground to make the surface roughness Ra value less than 1.6. Then Ti 3 Al alloy and GH710 superalloy were put into acetone solution, ultrasonically cleaned for 7 minutes, and dried in air. Install the above materials: place the intermediate layer 3 composed of Nb foil 2 and Ni foil 6 on TiAl / Nb alloy 5-Ti 3 Between Al and Ni-based superalloy 7-GH710, where Nb foil 2 and Ti 3 Al contact, Ni foil 6 and GH710 contact, construct the workpiece to be welded. Put the workpiece to be welded into the vacuum furnace, and place it between the upper pressure head 4 and the lowe...

Embodiment 3

[0022] Example 3: TiAl / Nb alloy Ti 2 Diffusion welding of AlNb and Ni-based superalloy GH4169.

[0023] Take a Nb foil with a thickness of 20 μm and a purity of 99.9wt.% and a Ni foil with a thickness of 15 μm and a purity of 99.9wt.%, put them in acetone, clean them ultrasonically for 15 seconds, and dry them in air. Use 1500 # SiC sandpaper on Ti 3 The surface of Al alloy and GH710 superalloy to be welded is ground to make the surface roughness Ra value less than 1.6. Then Ti 3 Al alloy and GH710 superalloy were put into acetone solution, ultrasonically cleaned for 9 minutes, and dried in air. Install the above materials: place the intermediate layer 3 composed of Nb foil 2 and Ni foil 6 on TiAl / Nb alloy 5-Ti 3 Between Al and Ni-based superalloy 7-GH710, where Nb foil 2 and Ti 3 Al contact, Ni foil 6 and GH710 contact, construct the workpiece to be welded. Put the workpiece to be welded into the vacuum furnace, and place it between the upper pressure head 4 and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com