Vibrating full-automatic production chain finishing machine

A finishing machine and assembly line technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

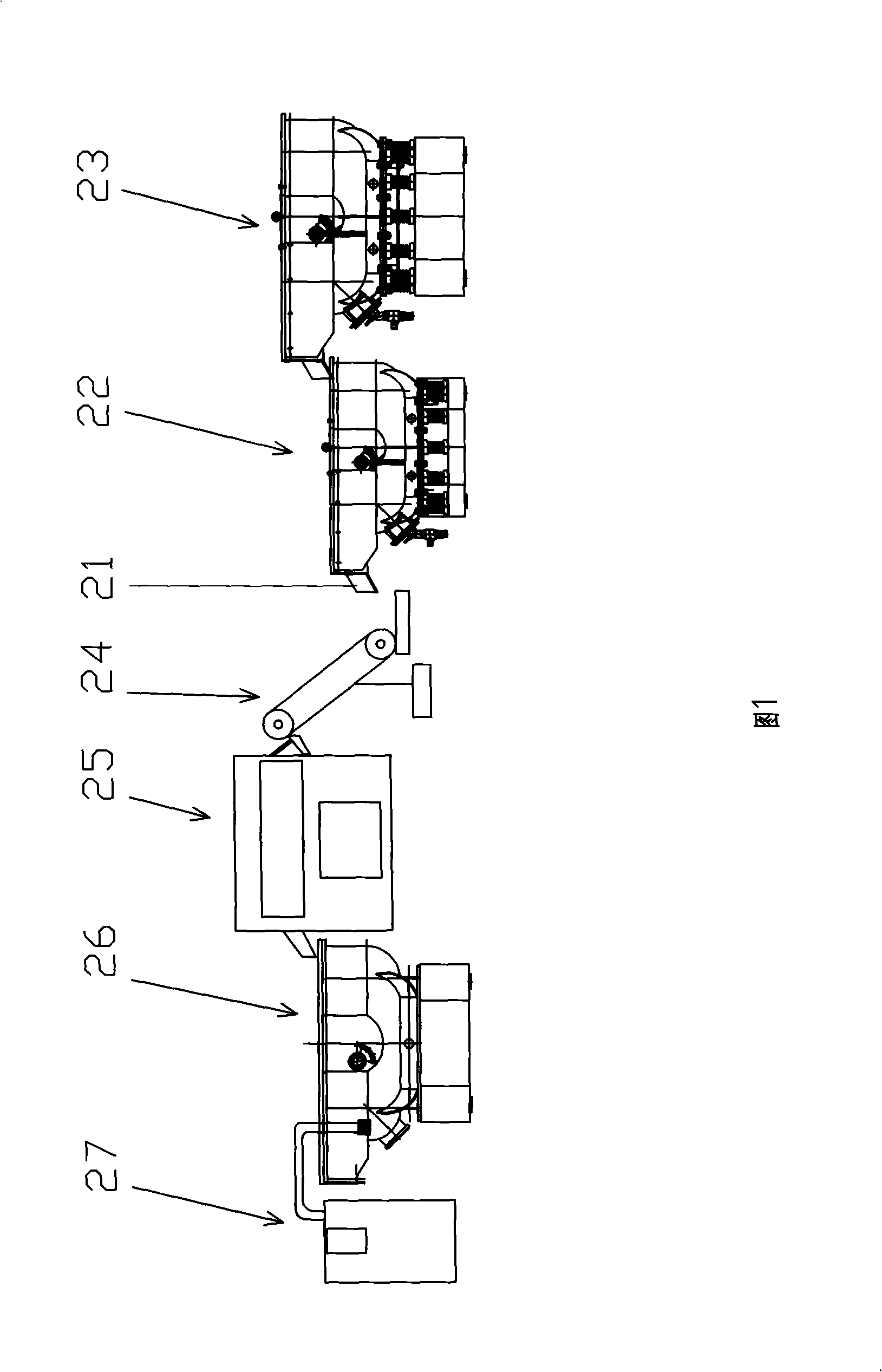

[0014] As shown in Figure 1: the first vibrating finishing machine 22 is an existing vibrating finishing machine, and the discharge chute 21 place of the first vibrating finishing machine 22 is connected with feeding machine 24, cleaning and dehydrating machine 25, corn Core drier 26, dehumidification dust collector 27, above-mentioned each equipment is all fixedly installed on the same support, makes it become the finishing processing production line of parts. Wherein vibrating finishing machine 22, feeder 24, corn cob dryer 26, dehumidification dust collector 27 are all existing equipments, can be purchased according to needs. Also can be provided with a second vibrating finishing machine 23 at the front end of the first vibrating finishing machine 22, first rough grinding by the second vibrating finishing machine 23 during work, then fine grinding by the first vibrating finishing machine 22.

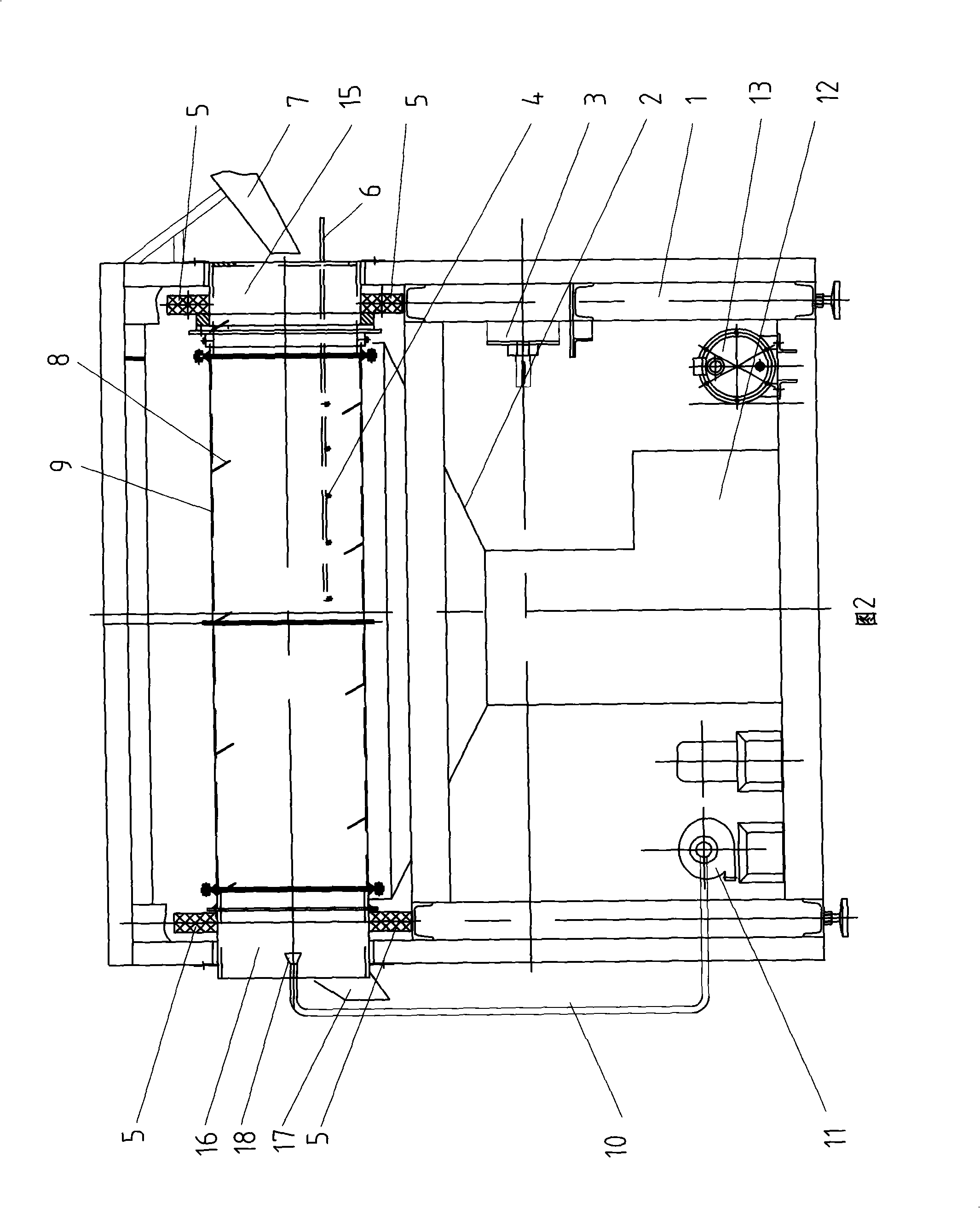

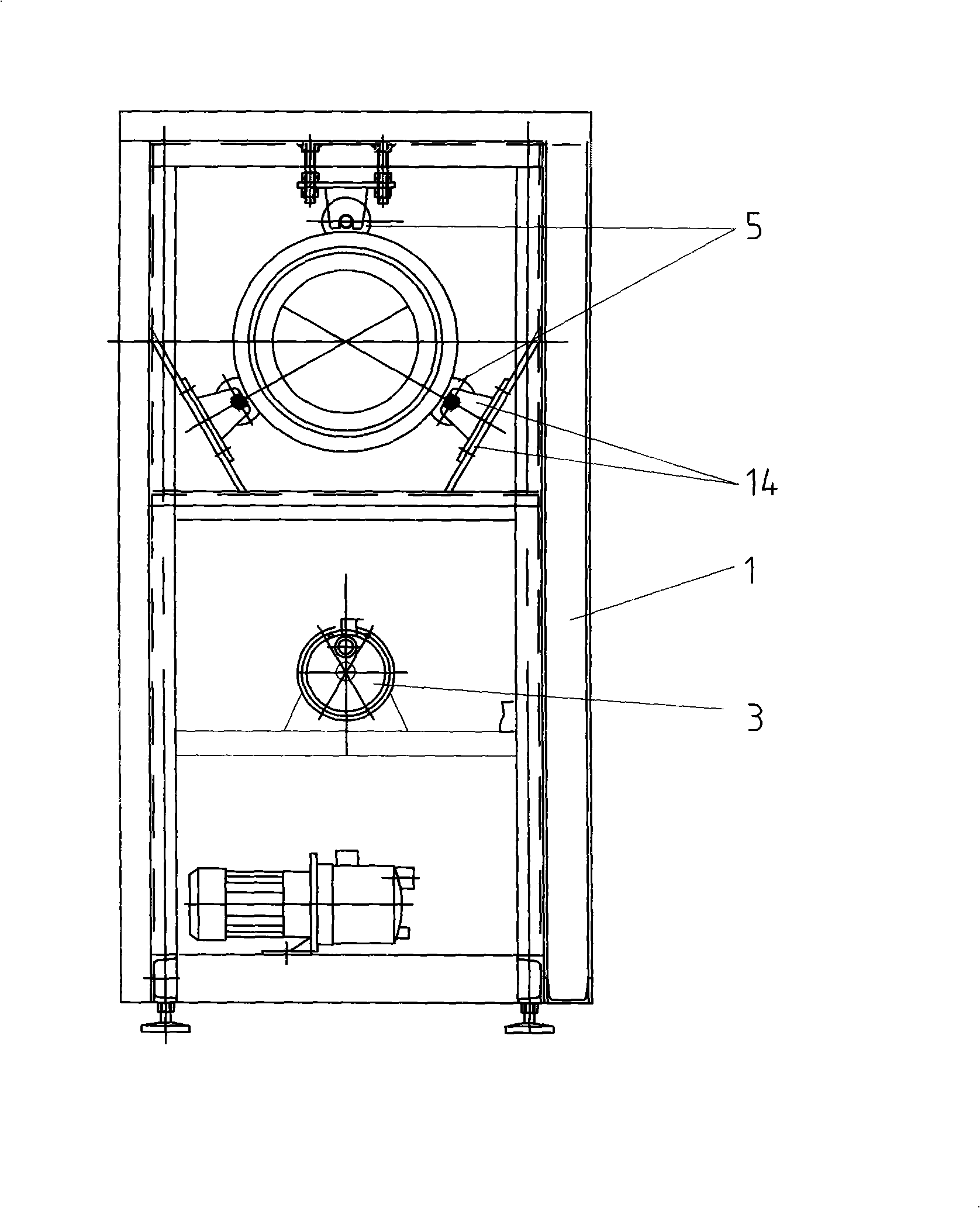

[0015] As shown in Figures 2 and 3: the structure of the cleaning dehydrator 25 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap