Main power system of concrete delivery pump and concrete delivery pump

A technology of a concrete delivery pump and a main power system, applied in the field of concrete machinery, can solve the problems of wasting main oil pump resources, incapable of fully exerting the oil pumping capacity of the main oil pump, increasing the manufacturing cost of the concrete delivery pump, etc. The effect of oil discharge flow and increased displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

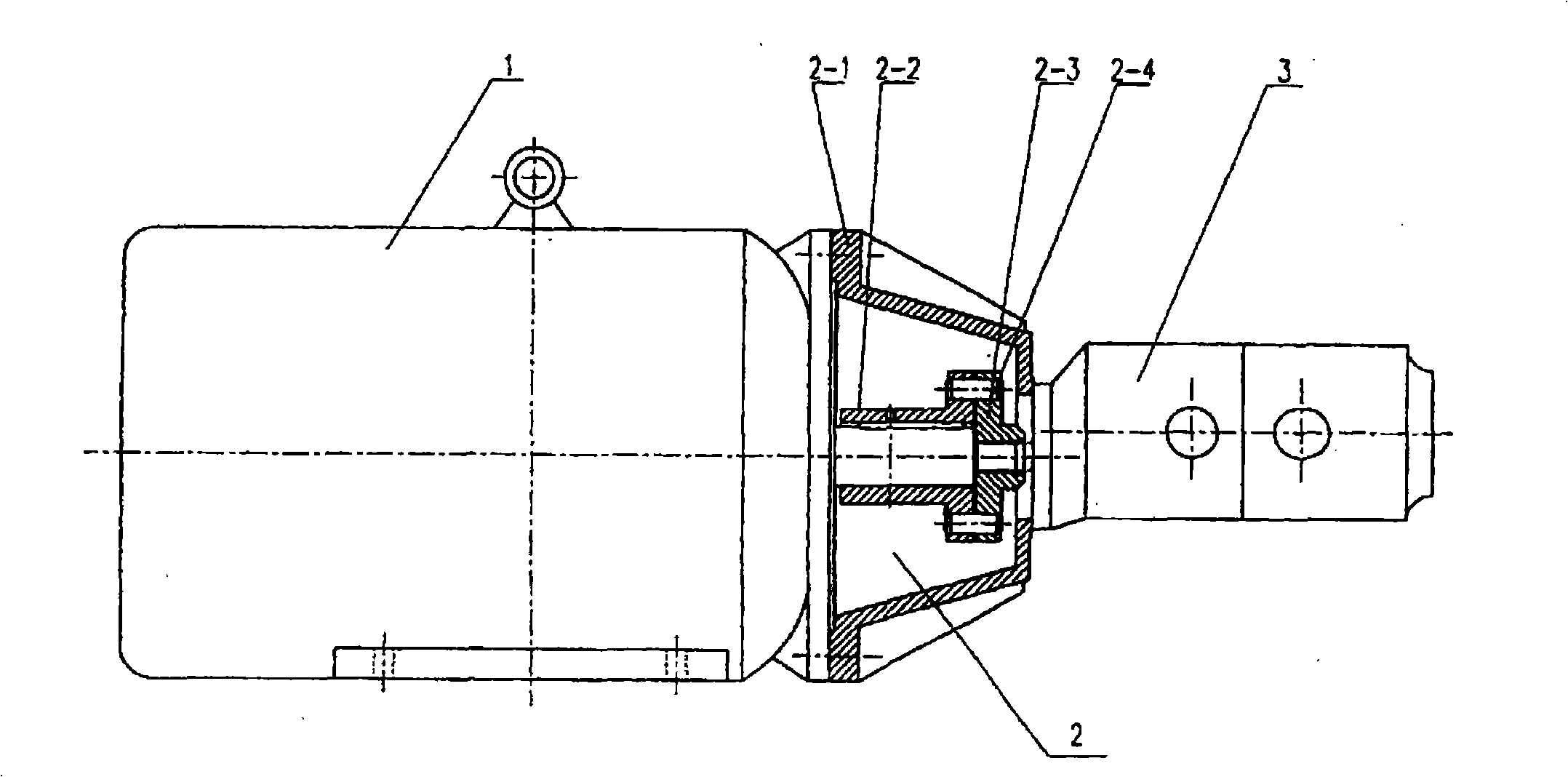

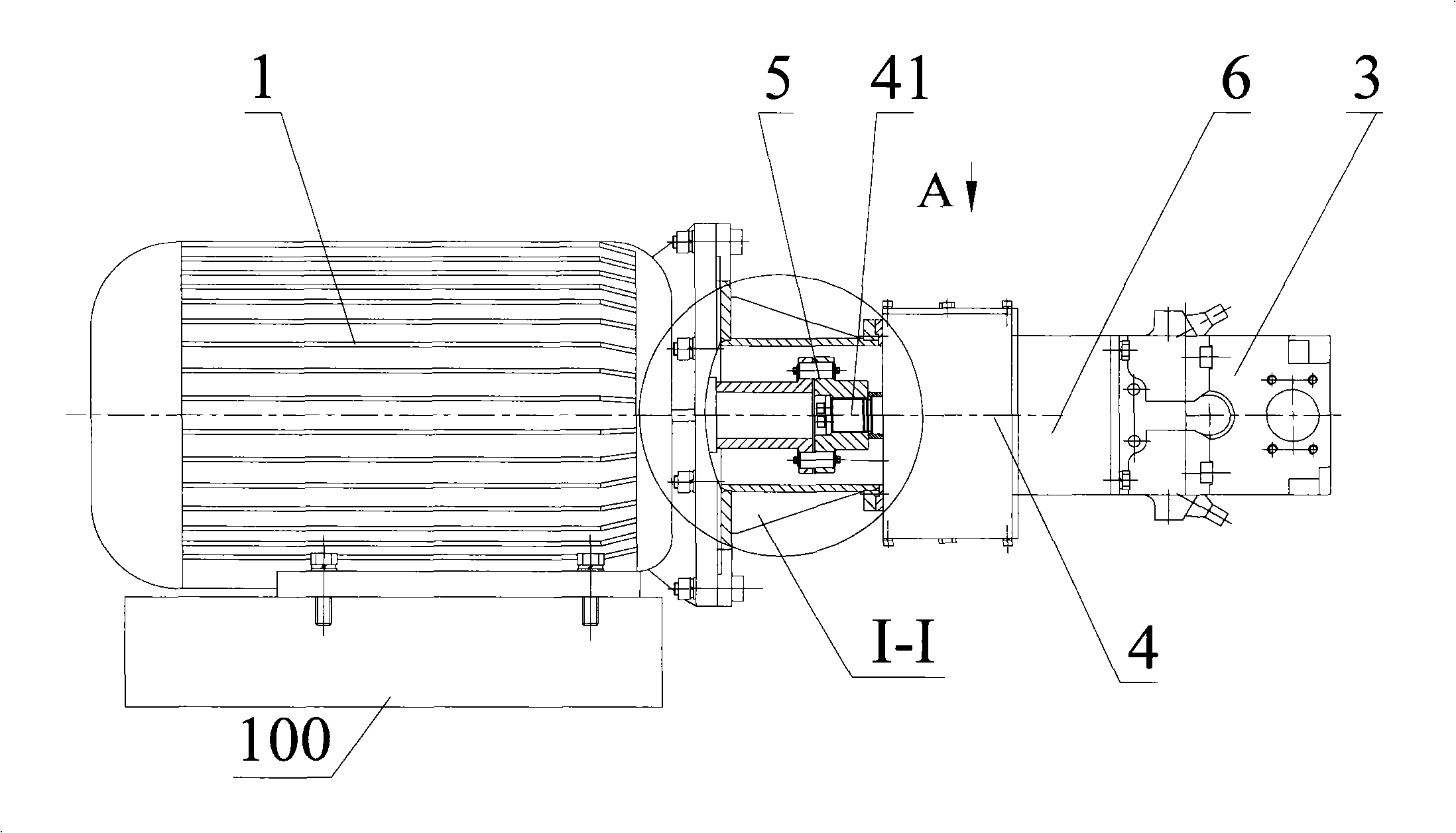

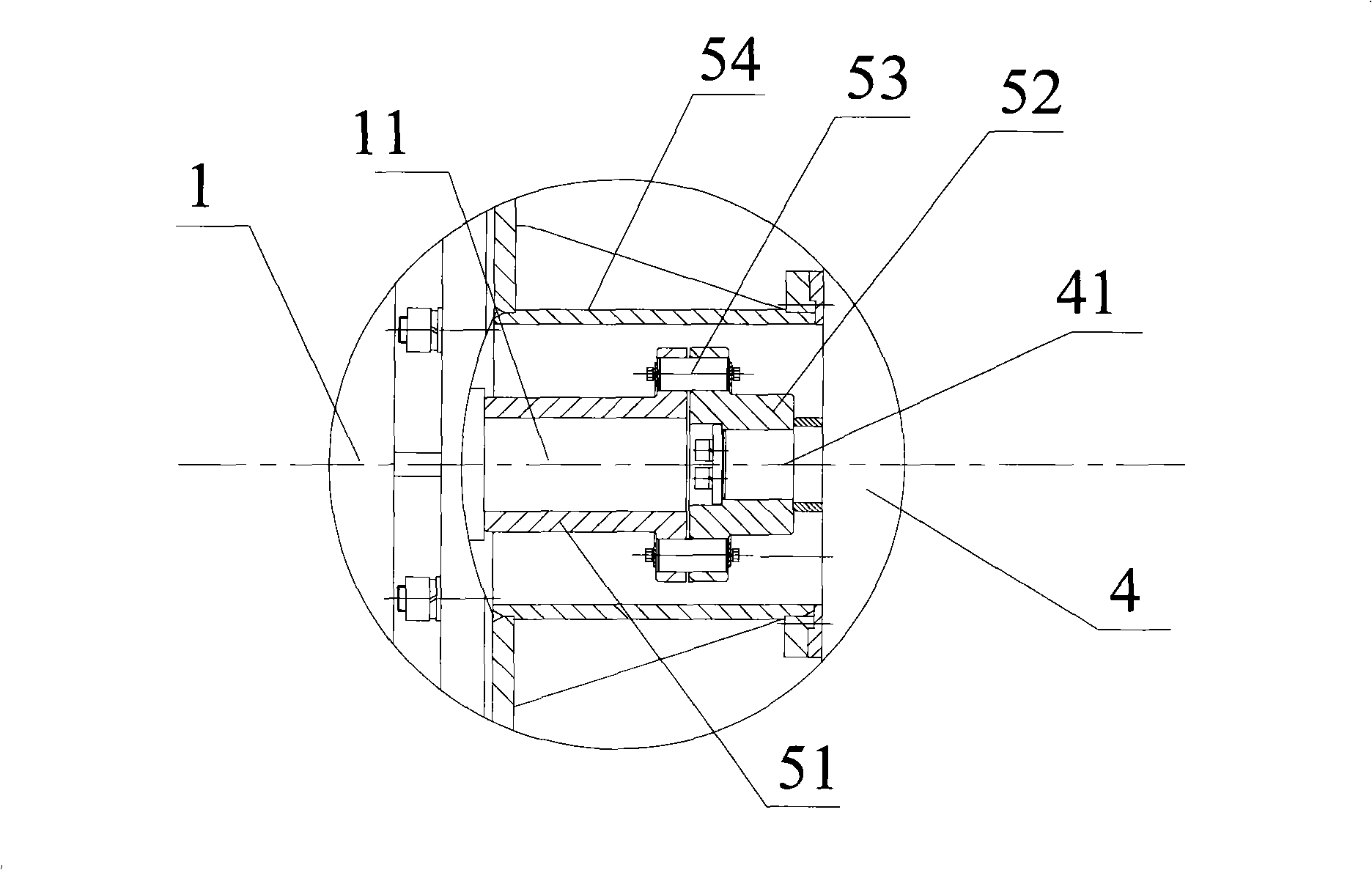

[0044] Embodiment 1 provides an active power system of a concrete delivery pump that uses gear transmission to increase speed, such as figure 2 As shown, the main power system of the concrete delivery pump provided in this example includes the motor 1, the first hydraulic pump 3, the couplings 5, 6, and the speed increaser 4. For the sake of clarity, the figure also shows the base 100, so The main power system of the concrete delivery pump described above is fixed on the base 100. Generally, the main power system of the concrete delivery pump includes a main oil pump and an auxiliary oil pump. In this example, the main oil pump includes the first hydraulic pump 3, and the first hydraulic pump 3 includes the first pump axis (not shown). In this example, in order to reduce the cost of the main power system of the concrete delivery pump, the first hydraulic pump 3 is a single hydraulic pump. The structure of the shaft coupling 5 or 6 and the speed increaser 4 will be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com