Superheated steam drain valve of lever guide type invert barrel

A technology of superheated steam and inverted buckets, applied in steam traps, mechanical equipment, etc., can solve problems such as affecting the performance of traps, unstable sealing, poor contact, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

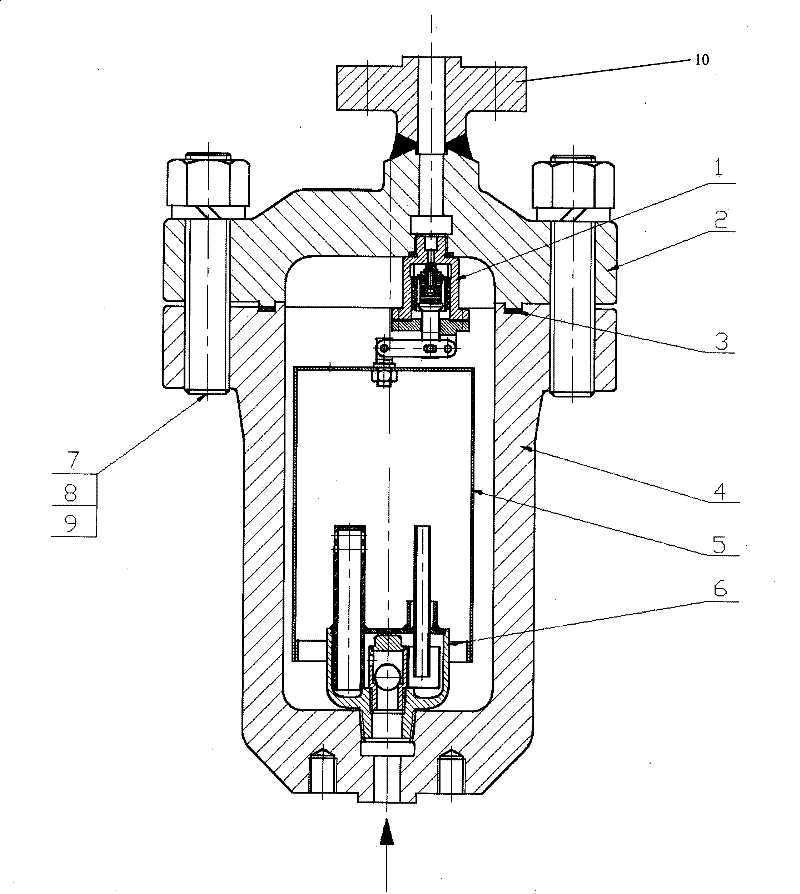

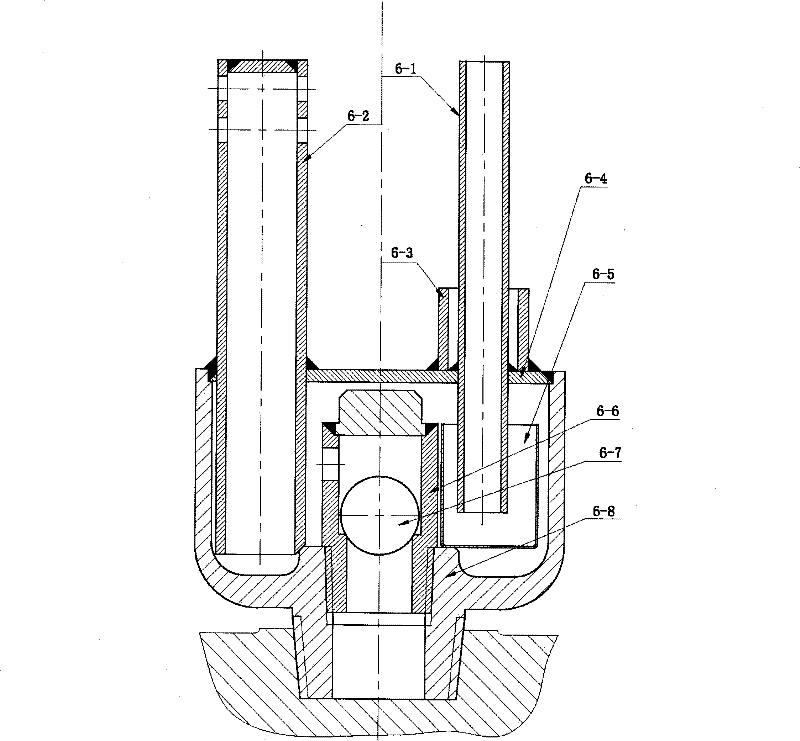

[0026] see Figure 1~3 , The present invention is provided with a lever pilot valve 1, a valve cover 2, a gasket 3, a valve body 4, an inverted bucket 5, a sump part 6, a stud 7, a nut 8 and a washer 9. The lever pilot valve 1 is set at the lower end of the outlet of the valve cover 2, the sump part 6 is set at the entrance of the lower end of the valve body 4, the gasket 3 is set in the sealing groove of the valve body 4, the valve cover 2 is covered on the valve body 4 and The external flange 10 and the inverted bucket 5 are set on the sump part 6 .

[0027] The bonnet 2 and the valve body 4 can be fastened and installed with stud bolts 7 , lock washers 9 and nuts 8 .

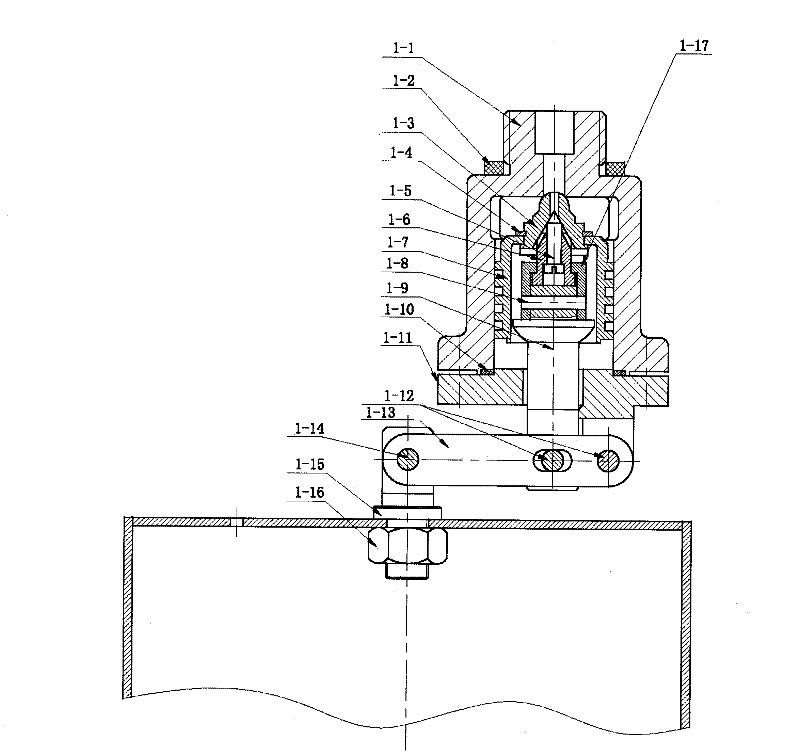

[0028]The lever pilot valve 1 is equipped with a valve seat body 1-1, a gasket 1-2, a main valve core 1-3, a circlip ring 1-4, a pilot valve core 1-5, a valve guide 1-6, and a piston 1- 7. Cylindrical pin 1-8, lower valve core 1-9, gasket 1-10, valve seat cover 1-11, connecting pin 1-12, lever 1-13, connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com