Probe for measuring pipe wall thickness

A technology of wall thickness measurement and pipe wall, which is applied in the field of special probes, can solve the problems of wasting materials, prolonging the detection time, and long construction period, so as to save time, reduce operation steps, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

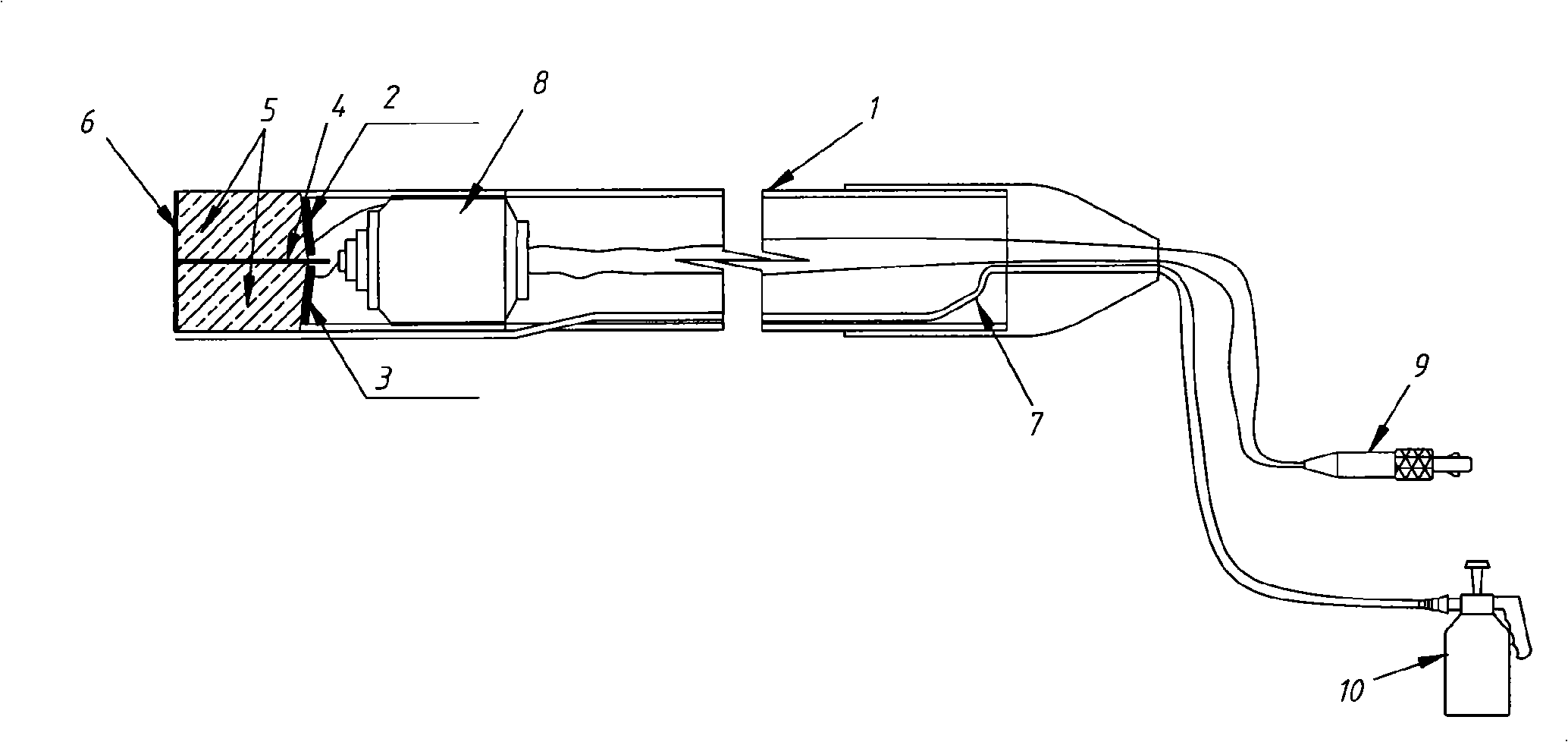

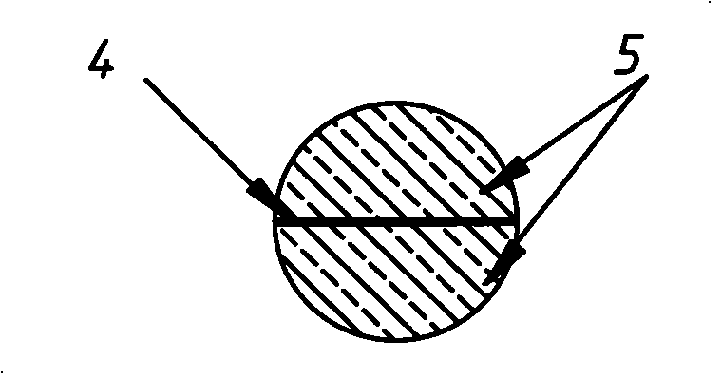

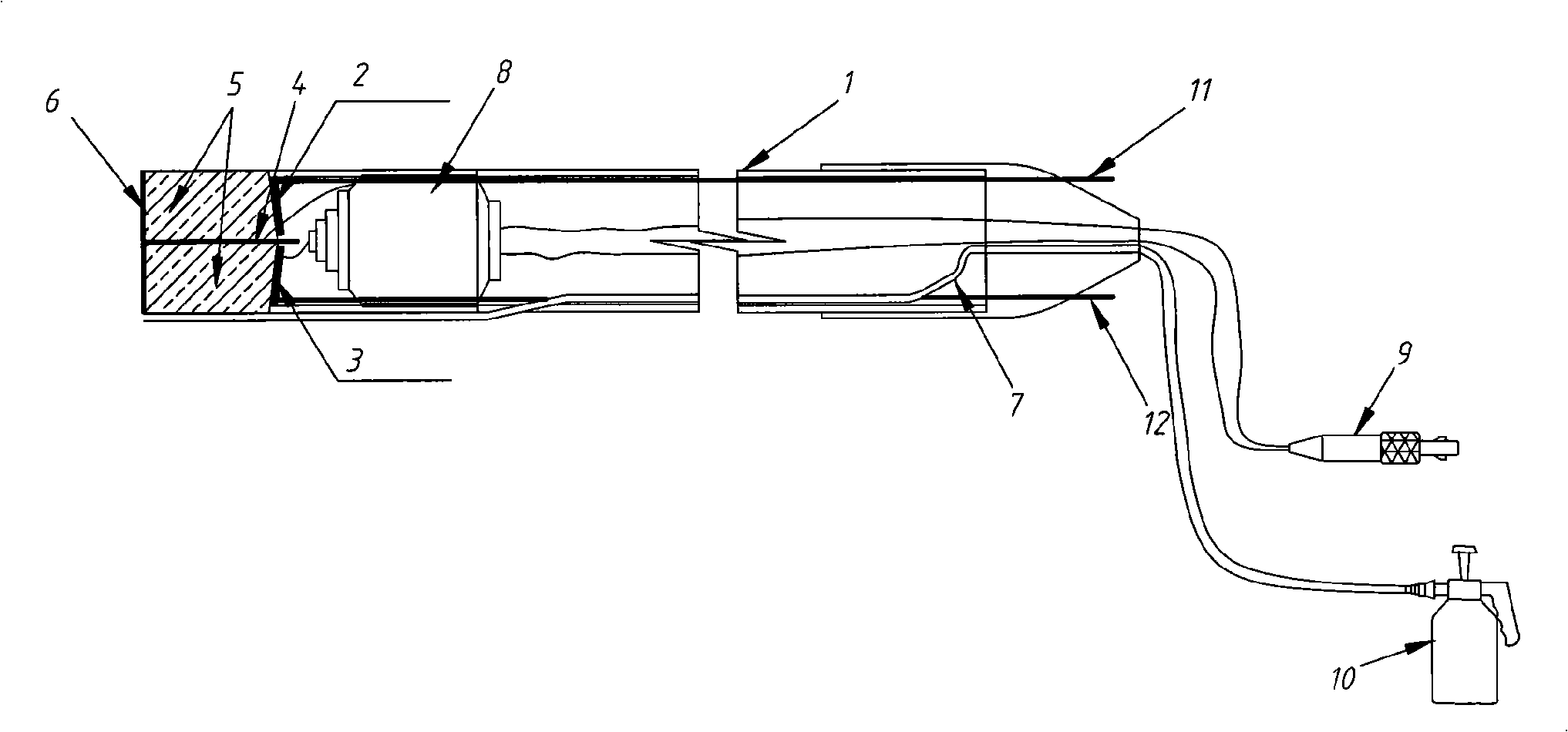

[0012] figure 1 It is a structural schematic diagram of a specific embodiment of the present invention, such as figure 1 As shown, the pipe wall thickness measuring probe includes a casing 1, an ultrasonic emitting crystal 2, an ultrasonic receiving crystal 3, a separation layer 4, a damping block 5, a protective film 6, and a couplant delivery tube 7. The crystal 2 and the ultrasonic receiving crystal 3 are located in the front part of the shell 1. The ultrasonic emitting crystal 2 and the ultrasonic receiving crystal 3 are connected to a joint 8 through a signal connection line, and then connected to an external connection joint 9 by a signal connection line, and finally connected to the ultrasonic measuring device. On the thickness meter, a damping block 5 is also respectively provided in front of the ultrasonic transmitting crystal 2 and the ultrasonic receiving crystal 3, combined with figure 2 As shown, the separation layer 4 separates the ultrasonic transmitting cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com