Piezoresistive transducer probe based on electric conduction high molecule sensitivity membrane and preparation method thereof

A technology of sensor probes and conductive polymers, applied in the field of force sensors, can solve the problems of no practical application, no quantitative accuracy, resolution, etc., achieve a large range, avoid membrane cracking and warping, and reduce contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

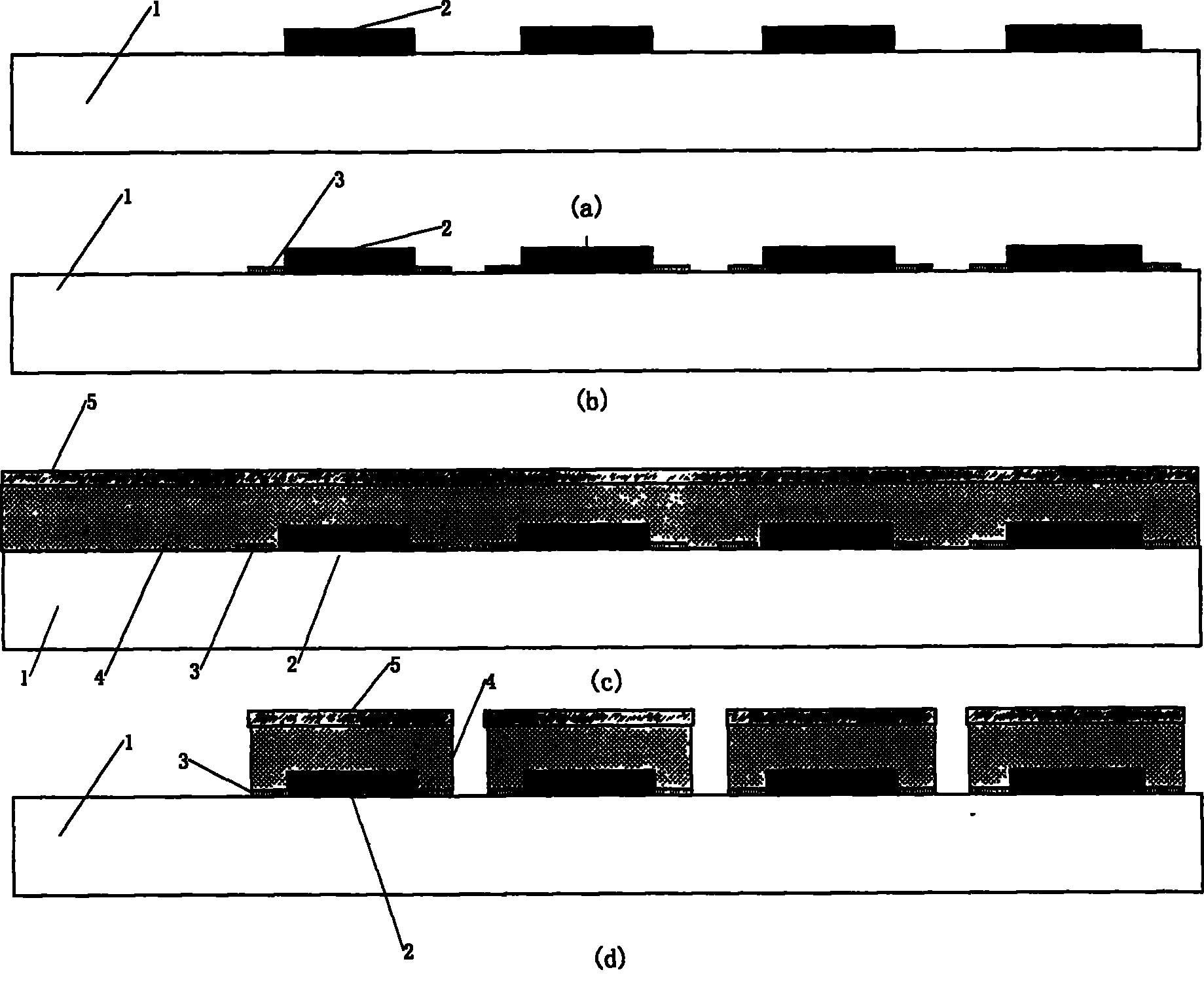

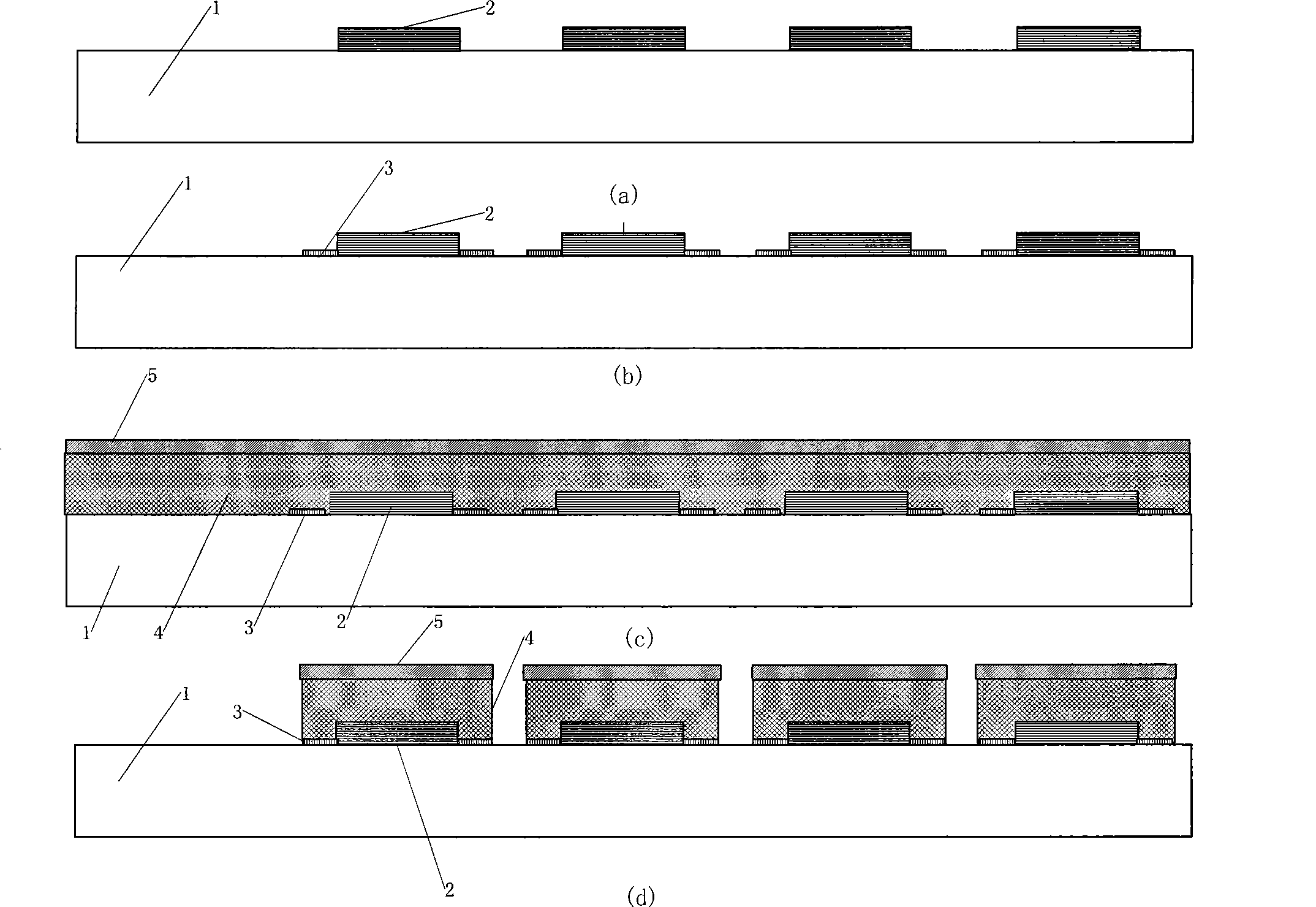

Method used

Image

Examples

Embodiment 1

[0047] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0048] b. Spray the surface treatment agent SAD-5 special surface treatment agent for silicone rubber on both sides of the electrode area, and dry for 0.5 hours for later use;

[0049] c. Mix conductive carbon black powder with an average diameter of 0.02 μm, coupling agent vinyltriethoxysilane and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: Components RTV silicone rubber: conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent = 100:1:1:300;

[0050] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 30°C, and the stirring time is 2 hours to prepare a suspension of carbon black and room temperature...

Embodiment 2

[0057] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0058] b. Spray the surface treatment agent on both sides of the electrode area and let it dry for 2 hours before use;

[0059] c. Mix conductive carbon black powder with an average diameter of 0.04 μm, coupling agent vinyltriethoxysilane and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: Components RTV silicone rubber: conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent = 100:5:2:400;

[0060] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 40°C, and the stirring time is 3 hours to prepare a suspension of carbon black and room temperature vulcanized silicone rubber, and ensure that the suspensi...

Embodiment 3

[0067] a. Rinse the substrate printed with interdigitated electrodes successively in 95% methanol solution and deionized water to remove organic pollutants, and blow dry in dry air or nitrogen;

[0068] b. Spray the surface treatment agent on both sides of the electrode area and let it dry for 1 hour for later use;

[0069] c. Mix conductive carbon black powder with an average diameter of 0.1 μm, coupling agent and liquid one-component room temperature vulcanized silicone rubber in n-hexane organic solvent; wherein, the mass ratio of each component is: one component room temperature vulcanized silicone rubber: Conductive carbon black powder: coupling agent vinyltriethoxysilane: n-hexane organic solvent = 100:15:2:500;

[0070] d. Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 60 ° C, and the stirring time is 4 hours to prepare a suspension of carbon black and room temperature vulcanized silicone rubber, and ensure that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com