Electrical machine, in particular synchronous motor, with redundant stator windings

A stator winding and stator technology, applied in the direction of AC motor control, shape/style/structure of winding conductors, electric components, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

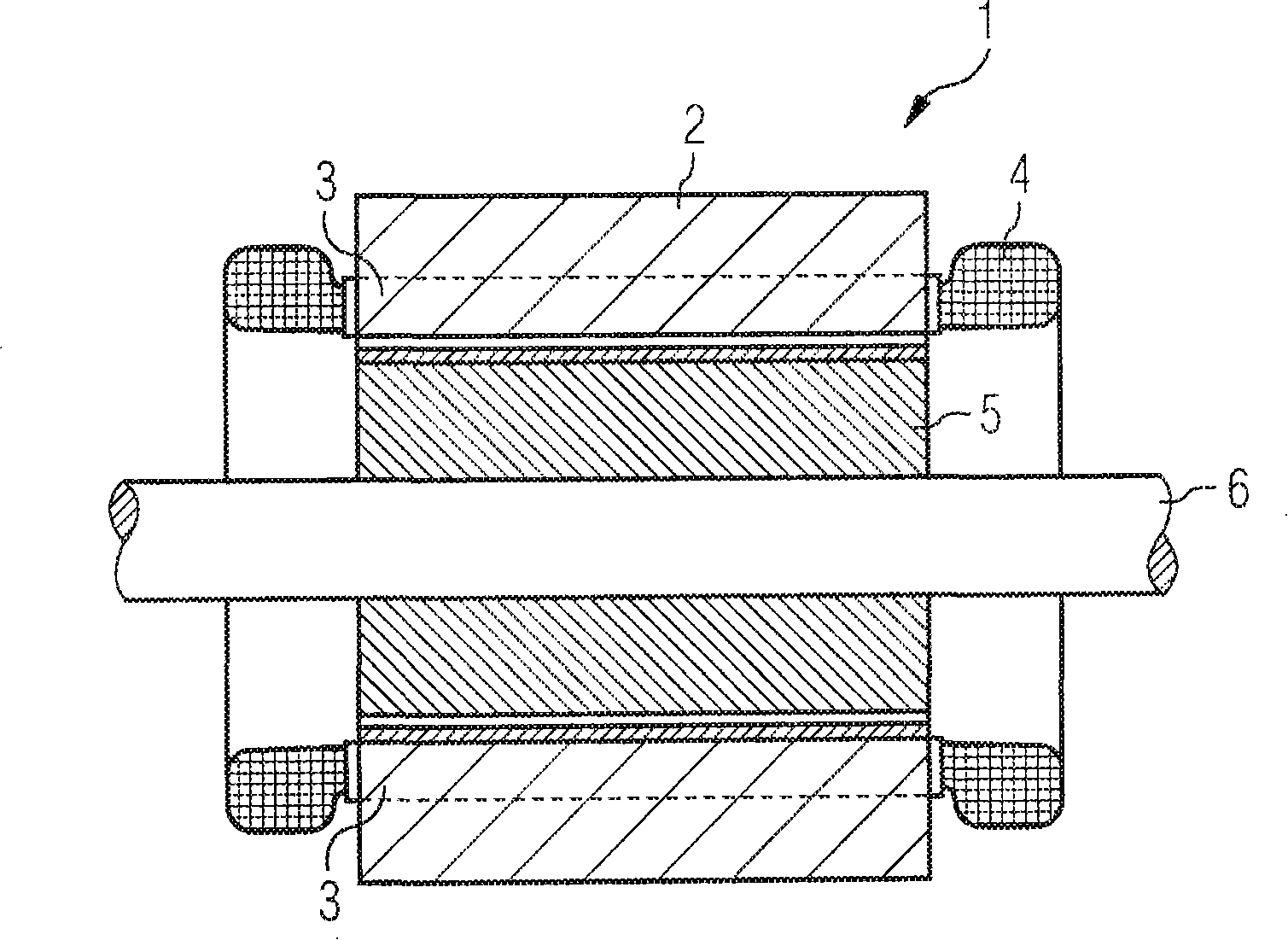

[0042] figure 1Shown is a longitudinal section of a prior art electric machine 1 taken along its axis of rotation. The motor 1 has a stator 2 and a rotor 5 mounted around a rotating shaft. The stator 2 has a stator core 3 with a stator winding 4 for generating a rotating magnetic field. The stator winding 4 has a plurality of multi-phase (in particular three-phase) winding systems which are not shown in detail. The stator core 3 and the rotor core are usually implemented as laminations in order to achieve the purpose of reducing eddy current losses. Reference sign 6 denotes a rotor shaft which is a part of rotor 5 .

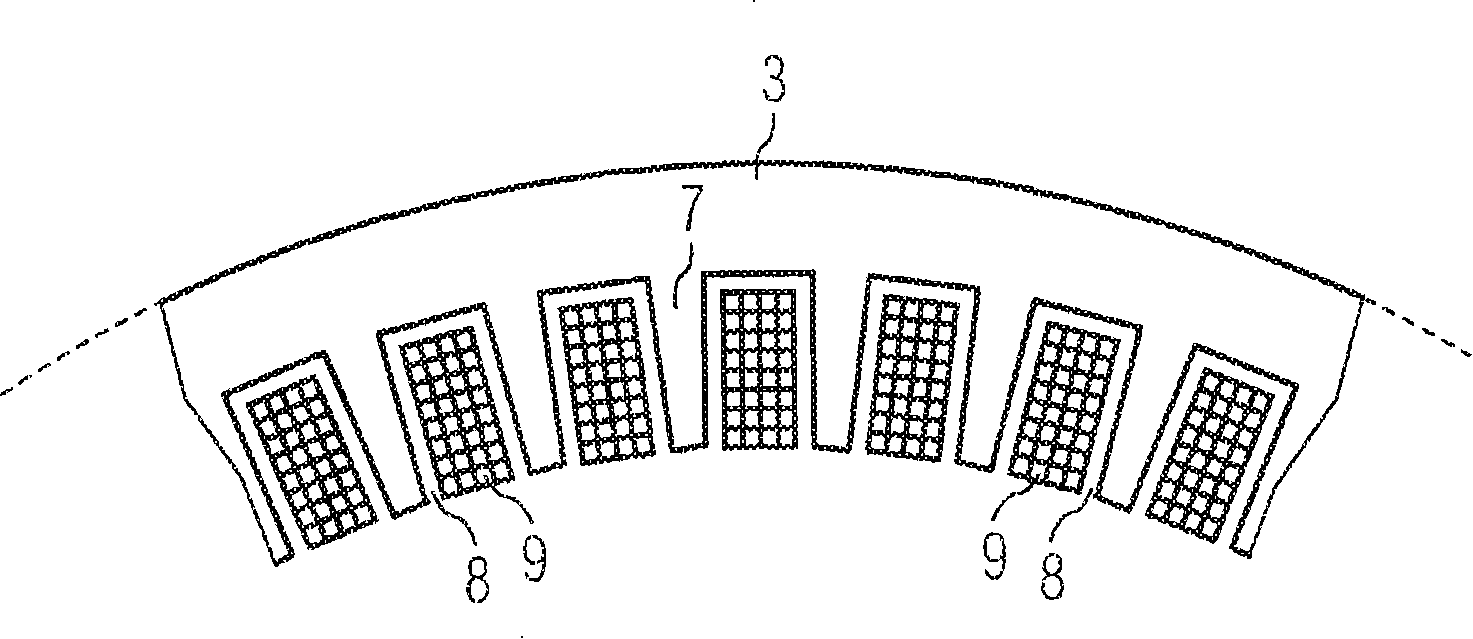

[0043] figure 2 Shown is a partial view of the laminations of the stator core 3 of the motor of the present invention. The electrical machine may be an electric motor or a generator. The motor can be a synchronous motor or an asynchronous motor. The electric machine is in particular a large electric machine with a rated power of at least 10 kW, especially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com