Welding repair method of iron casting

A technology of iron castings and welding methods, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of small fracture block area, thick workpiece thickness, and inability to carry out welding repairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Attached below Figure 1-7 The preferred embodiments of the present invention are given to describe the technical solution of the present invention in detail.

[0018] The welding repair method for iron castings mainly includes two steps of processing fracture blocks and welding repair.

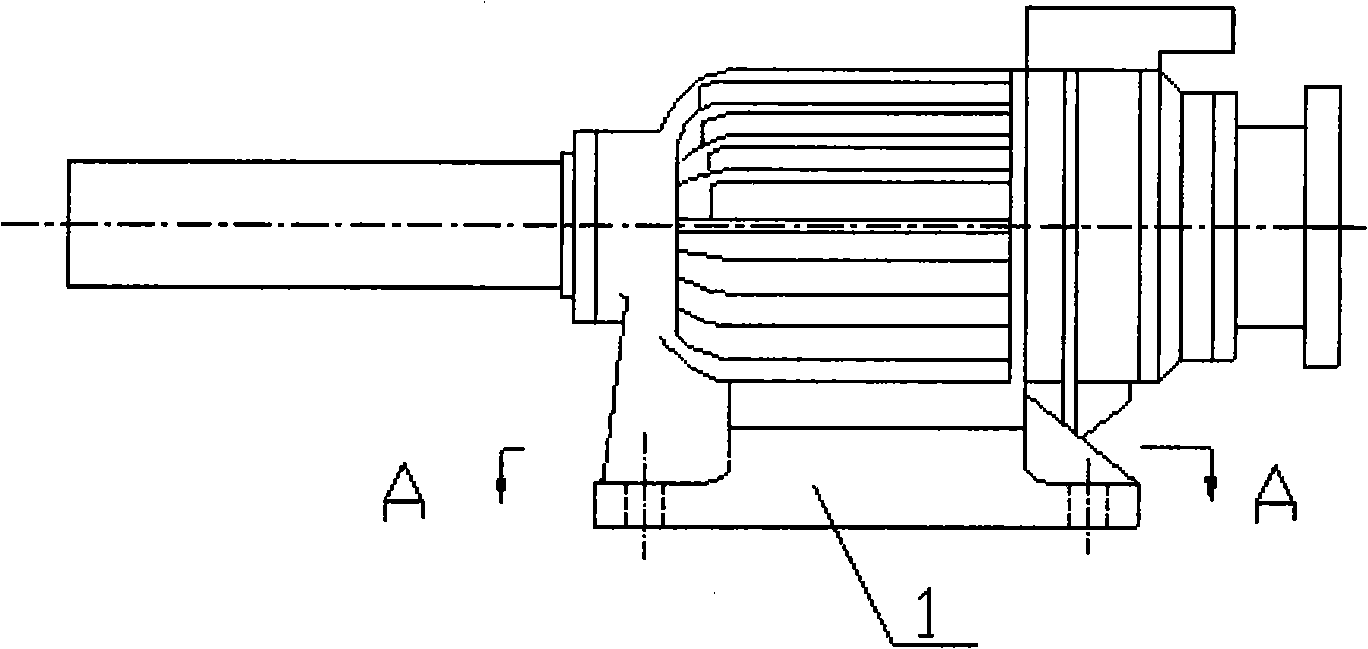

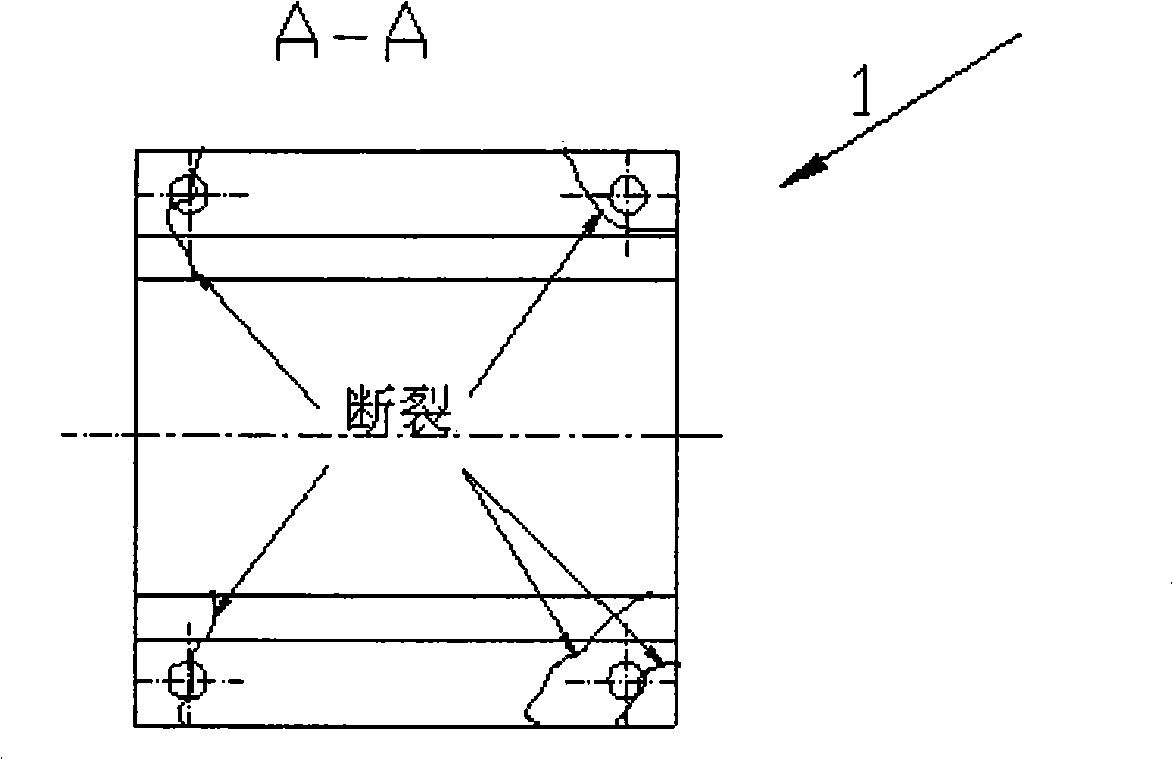

[0019] 1. Deal with the broken block of the cast iron base

[0020] (1) The fracture blocks 2 of the cast iron base 1 are grouped correspondingly.

[0021] (2) Perform groove grinding on the end faces 21 of the corresponding fracture blocks 2 to grind out a groove with an included angle of 60 degrees.

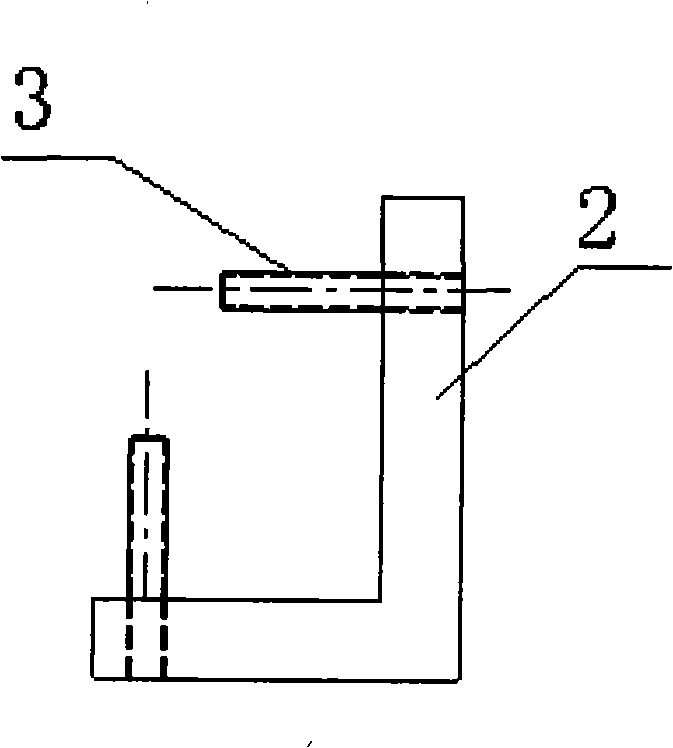

[0022] (3) Drill holes on the end faces of the corresponding fracture blocks 2 and thread them. According to the stress and size of the fracture blocks, install stainless steel bolts 3 ranging from φ6 to φ10mm on each fracture block, and then connect the two The block break blocks are inlaid together so that the stainless steel bolts 3 are arranged in a vertical and horizontal networ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com