Column crane special for movable arm type group tower

A technology of tower crane and tower grouping, which is applied to cranes and other directions, can solve the problems of reduced construction efficiency, low safety factor, low construction efficiency, etc., and achieve the effects of improving construction efficiency, high safety factor and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

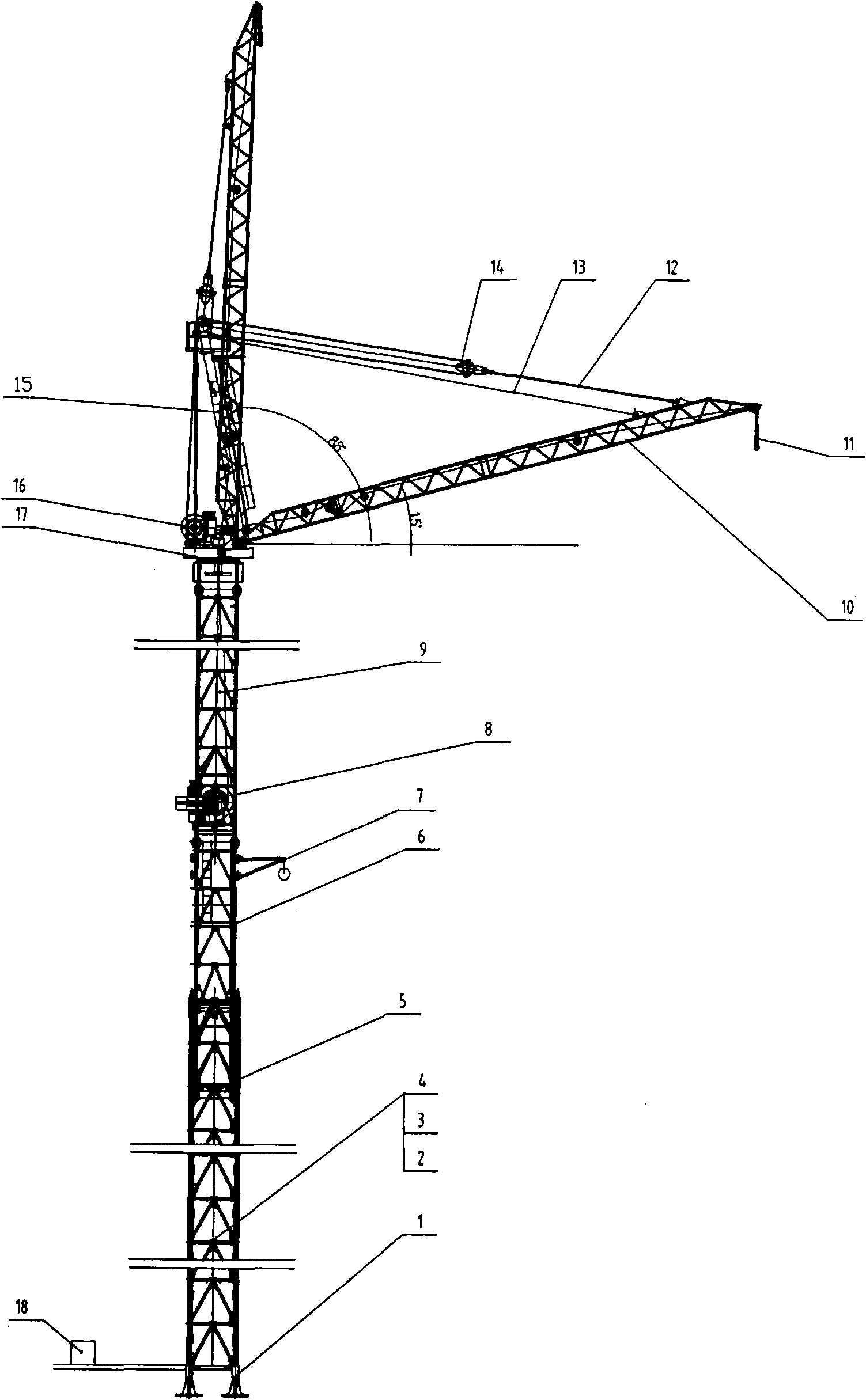

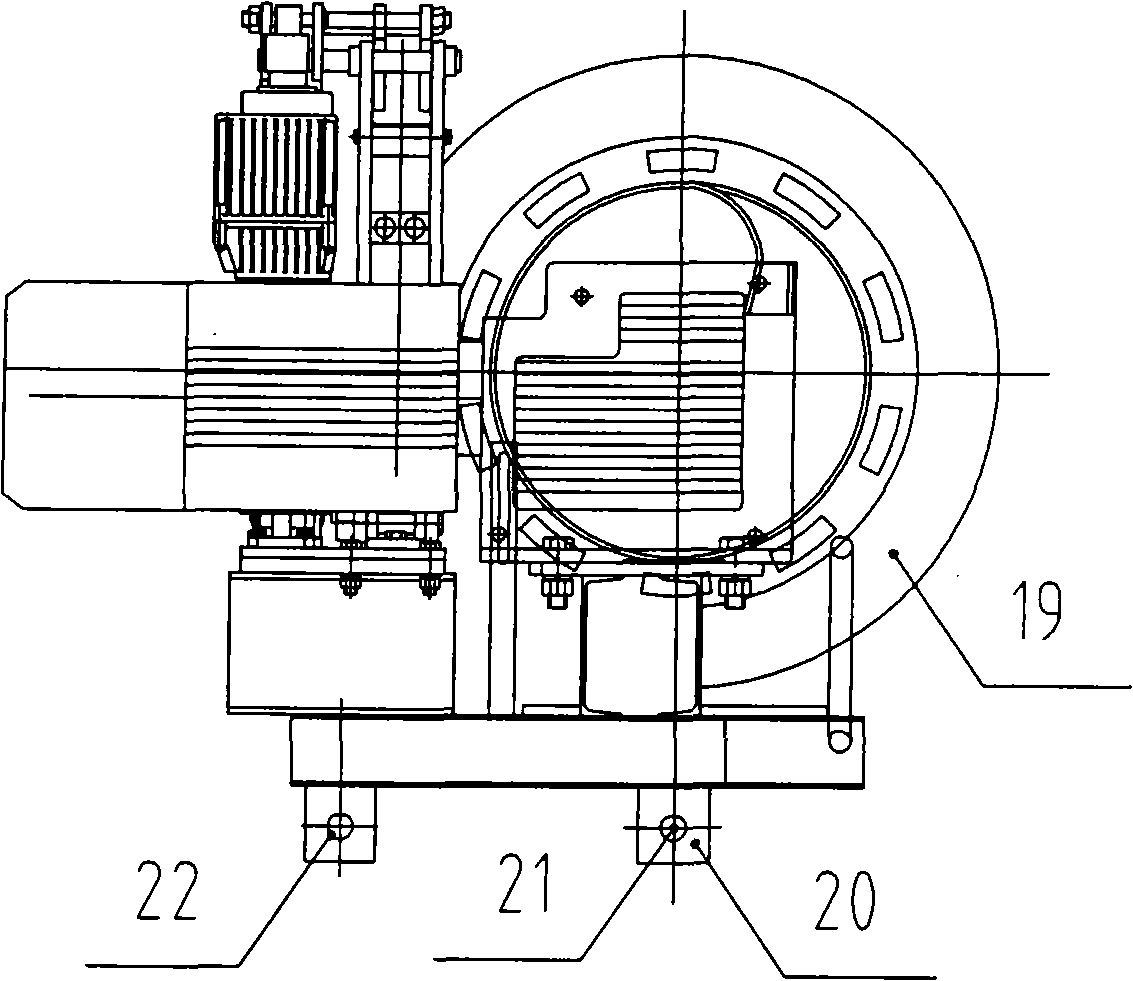

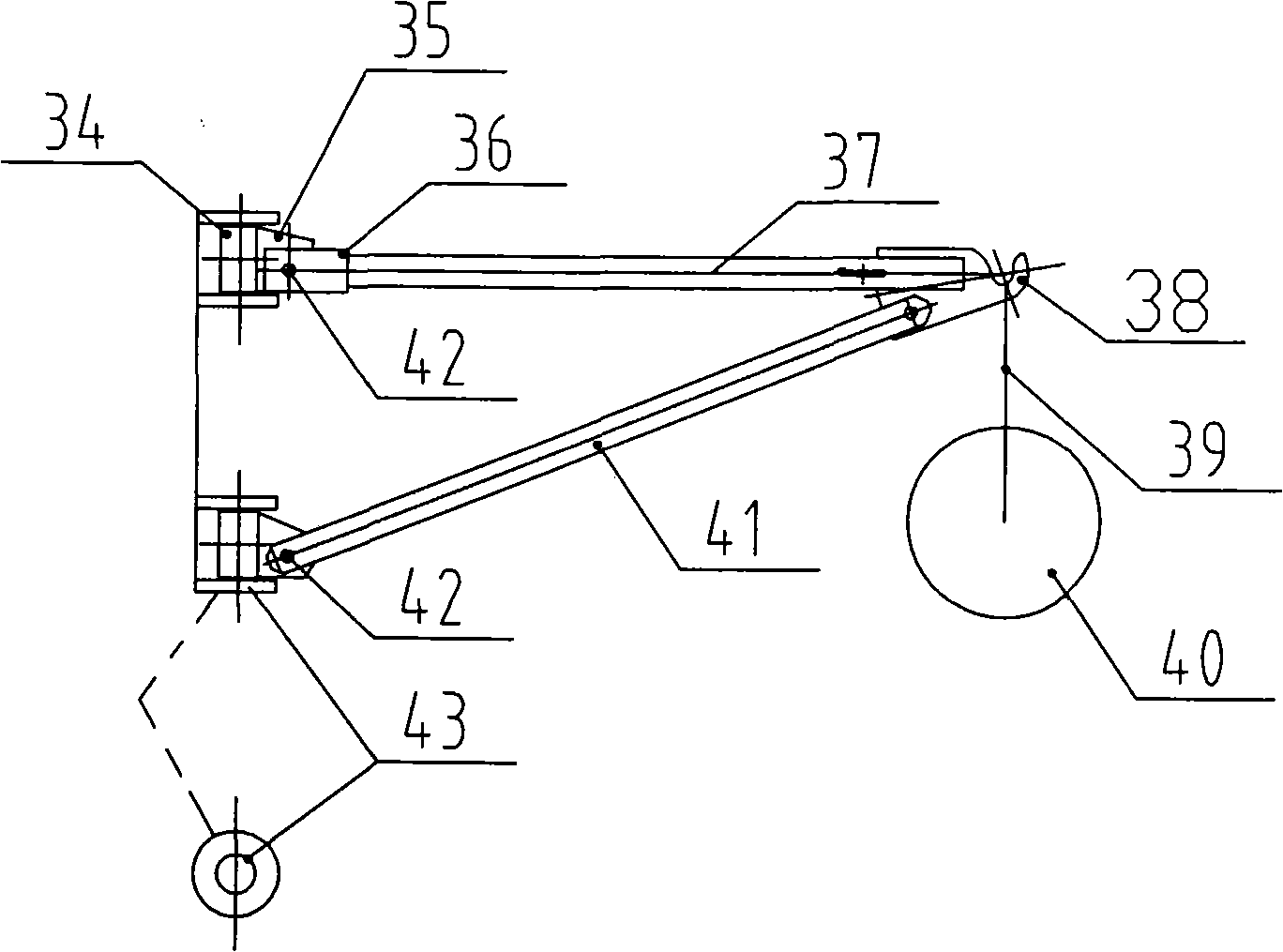

[0023] See figure 1 Shown: A special tower crane for luffing jib tower assembly. The boom can be raised up to 89° in the vertical plane. It includes fixed feet 1, standard section 2, rest platform 3, standard channel 4, and lifting device 5. Inner tower section for lifting 6. Hanger for demolition of tower 7. Lifting mechanism 8. Inner tower section for lifting 9. Boom assembly 10, hook pulley group 11, luffing rope 12, safety rope 13. The luffing pulley group 14, the tower top strut 15, the luffing mechanism 16, the turning assembly 17, and the driver's cab 18. The crane has no balance boom.

[0024] The upper end of the standard section is connected to the inner tower section for jacking through the existing connecting mechanism; the jacking device is installed at the lower end of the inner tower section for jacking, which is a prior art, the upper end of the inner tower section for jacking The inner tower section for lifting is fixedly connected by the existing fishplate and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com