New multifunctional organic micropowder synthesis method

A synthetic method and multi-functional technology, applied in the field of preparation of functional polymer materials, can solve the problems of pulverization and organic solvent application dispersion difficulties, research literature reports have not been found, and the extinction effect has no obvious advantages, etc., to achieve excellent extinction effect , excellent adhesion, high weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

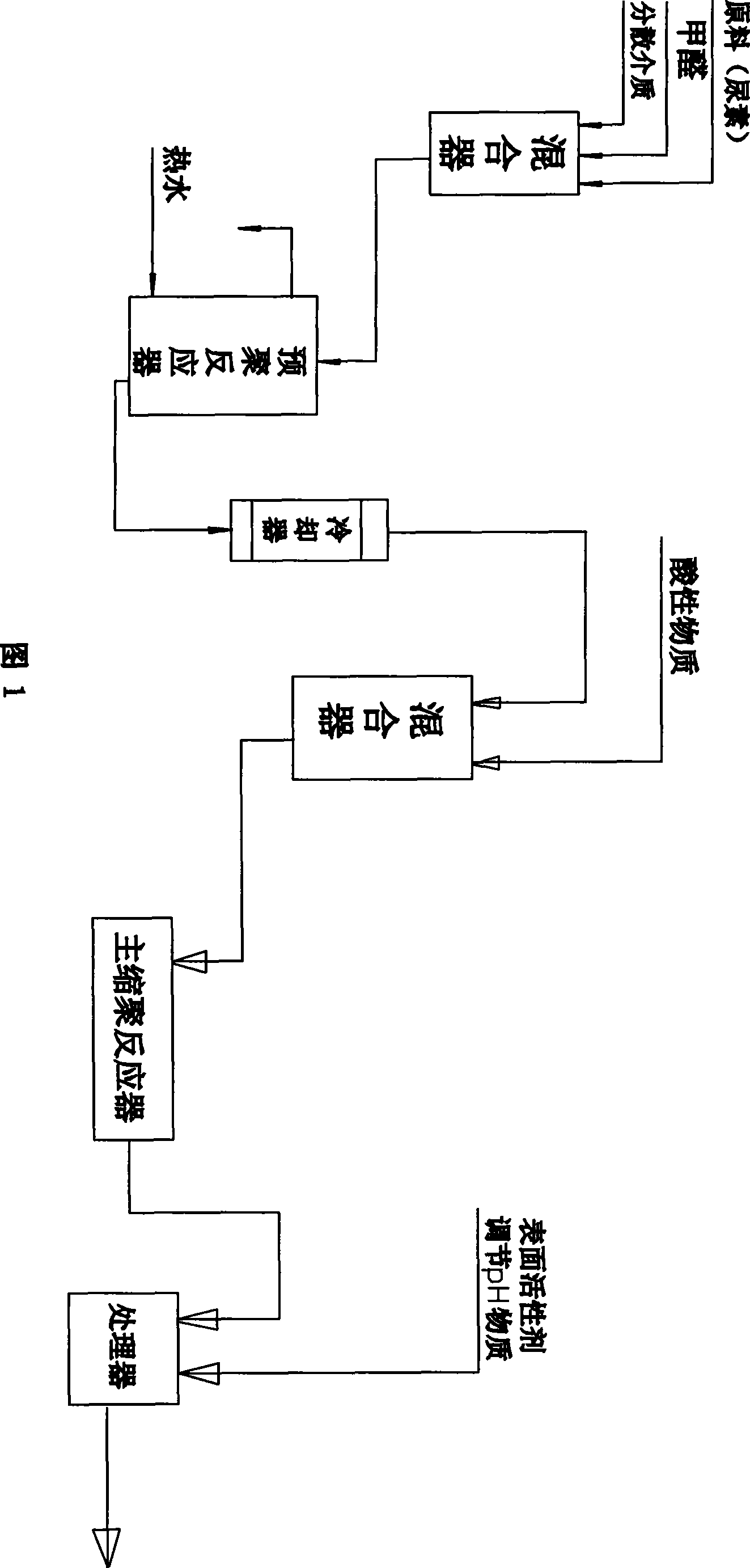

Method used

Image

Examples

Embodiment 1

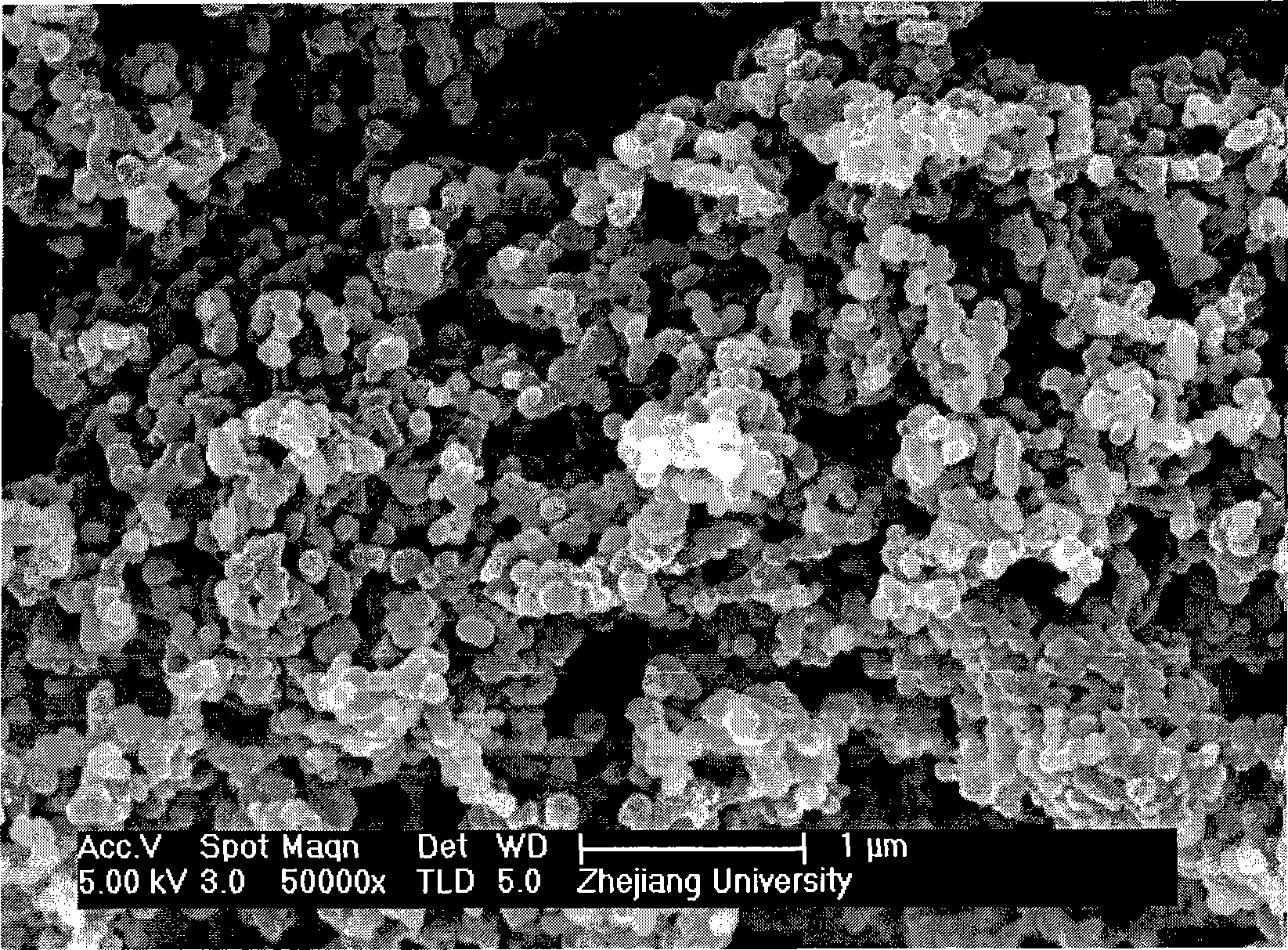

[0036] Embodiment 1: 9 parts (weight) carboxymethyl cellulose is dissolved in 600 parts of water, add mixer, start to stir, then add 180 parts of urea, 90 parts of solid formaldehyde, adjust pH value to 7.0 with sodium carbonate; Mix well Finally, transfer the material to the prepolymerization reactor, start stirring, start to heat up to 70°C, and maintain the temperature for 2 hours; the prepolymer is cooled to 40°C through the cooler, enters another mixer, and adds Sulfuric acid adjusts the PH of the prepolymer to 1.5, then the prepolymer enters the main polycondensation reactor, heats up to 75°C, maintains the temperature for 1 hour, transfers the product to a neutralization mixer, adds 1200 parts of water, 0.27 parts Span40, disperse and wash, adjust its pH value to 7.0 with sodium carbonate, filter, vacuum dry, and pulverize to obtain the product. The average particle size of the fine powder is 3.7 microns, and the specific surface area is 14m 2 / g, the porosity is 1.183...

Embodiment 2

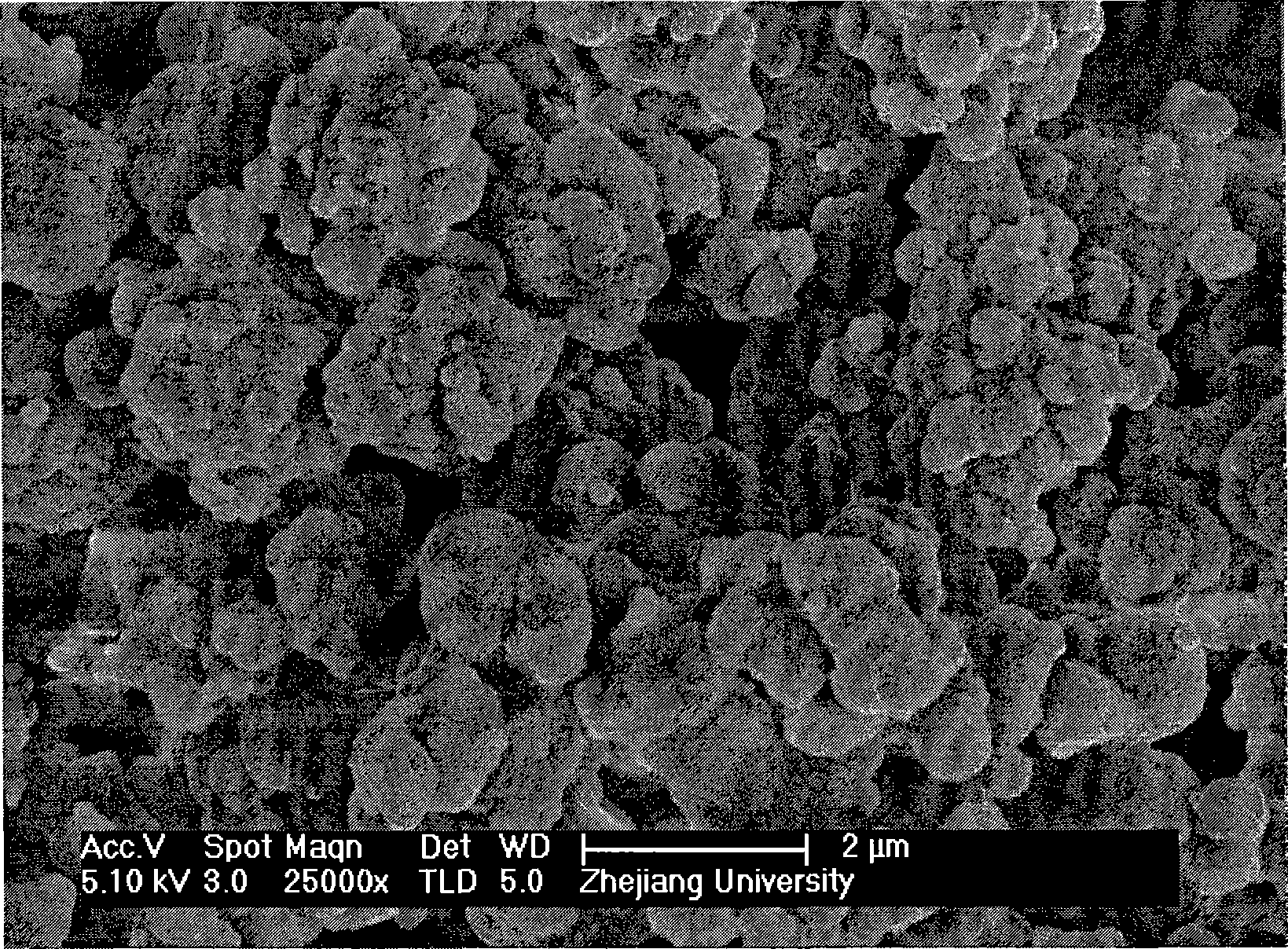

[0037] Example 2: Dissolve 6 parts of PVP in 900 parts of ethanol, add to the mixer, start stirring, then add 100 parts of urea, 42 parts of solid formaldehyde, adjust the pH value to 7.5 with ethanolamine; after mixing evenly, transfer the material to In the prepolymerization reactor, start stirring, start to heat up to 70°C, and maintain the temperature for 1.5 hours; the prepolymer is cooled to 50°C through the cooler, and then enters another mixer, and citric acid is added to it to adjust the pH of the prepolymer 1.0, then let the prepolymer enter the main polycondensation reactor, heat up to 75 ° C, maintain the temperature for 1 hour, transfer the product to a neutralization mixer, add 1000 parts of ethanol, 0.3 parts of organosilane, disperse and wash, Adjust the pH value to 7.3 with triethanolamine, filter, vacuum dry, and pulverize to obtain the product. The average particle size of the fine powder is 2.5 microns, and the specific surface area is 16m 2 / g, the porosi...

Embodiment 3

[0038] Example 3: Dissolve 12 parts of PVA1788 in 600 parts of water, add to the mixer, start stirring, then add 120 parts of urea, 42 parts of melamine, 100 parts of solid formaldehyde, adjust the pH value to 7.0 with sodium carbonate; after mixing evenly, then Transfer the material into the prepolymerization reactor, start the stirring, start to heat up to 70°C, and maintain the temperature for 2 hours; the prepolymer is cooled to 40°C through the cooler, enters another mixer, and adds sulfamic acid to it Adjust the prepolymer PH to 1.5, then let the prepolymer enter the main polycondensation reactor, heat up to 80°C, maintain the temperature for 1.5 hours, transfer the product to the neutralization mixer, add 800 parts of water, 0.27 parts of Span40 , disperse and wash, adjust the pH value to 7.0 with sodium carbonate, filter, vacuum dry, and pulverize to obtain the product. The average particle size of the fine powder is 3.2 microns, and the specific surface area is 18m 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com