Cleaning of electrostatic chucks using ultrasonic agitation and applied electric fields

An electrostatic chuck, ultrasonic technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increased separation time, separation failure, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] The cleaning processes provided below, which may be used to clean new and used ESCs, are illustrative and not limiting. To establish a baseline for determining the effectiveness of the cleaning process, two silicon wafers were electrostatically clamped on the ESC prior to cleaning without etching the wafers. This ESC was previously used to clamp the wafer during dielectric etch. Since the ESC is used, the ceramic surface of the ESC has been exposed to plasma. Consequently, the ceramic surface of the ESC is highly contaminated with contaminant particles that have to be removed by cleaning.

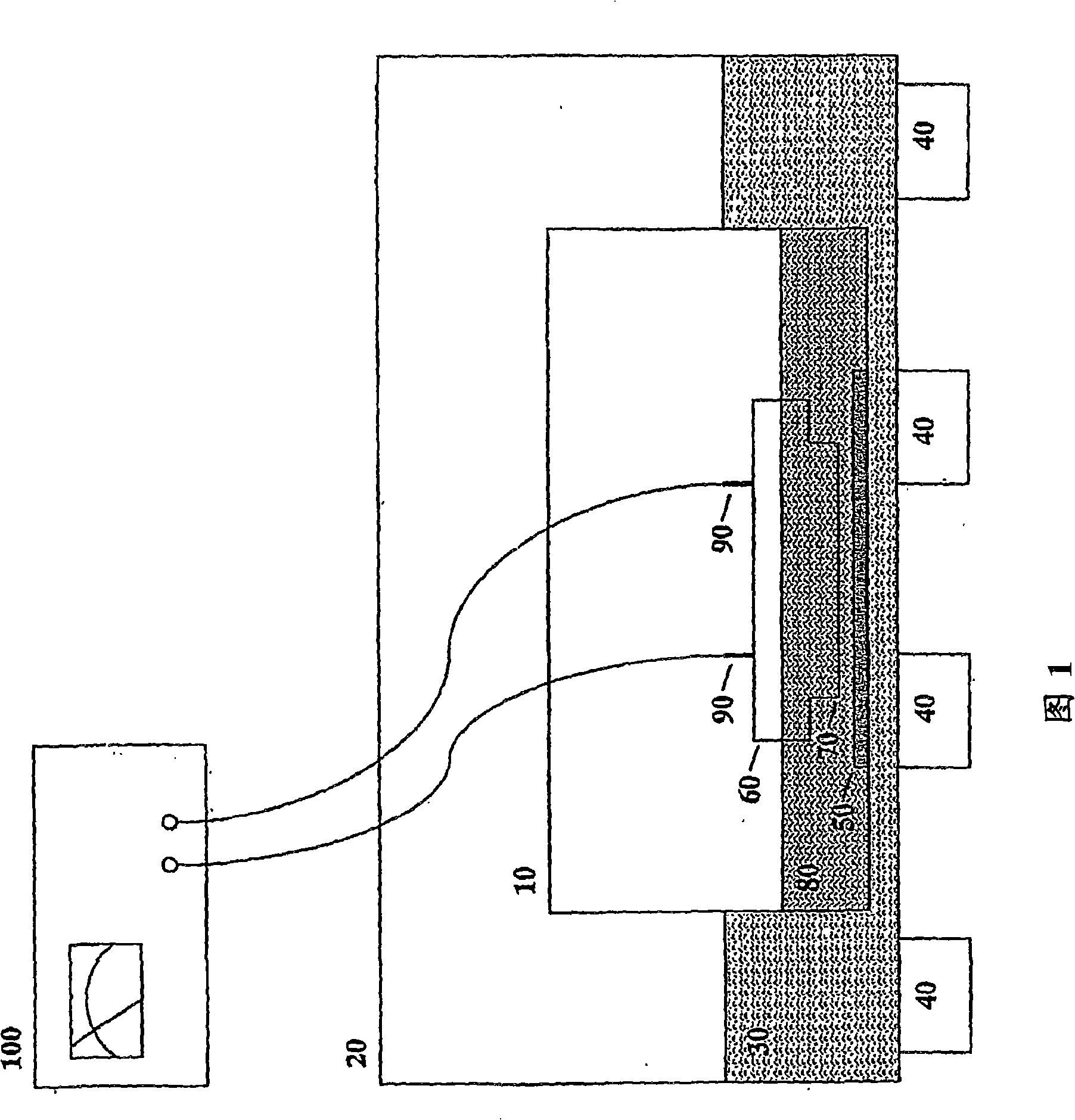

[0014] According to the figures, in order to reduce the amount of dielectric fluid used in the cleaning process, a plastic tank 10 may be placed within an ultrasonic tank 20 containing approximately 4.7 gallons of deionized water 30 so that there is Deionized water. The ultrasound box 20 is typically stainless steel and has an ultrasound transmitter 40 (its power supply not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com