Rotor cutting processing method using running balance indicating machine and special device thereof

A dynamic balancing machine and cutting processing technology, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of inability to restore the original state, enlargement of the fastening hole of the compressor impeller, scrapping of the compressor impeller, etc. The process of removing and assembling the impeller and the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

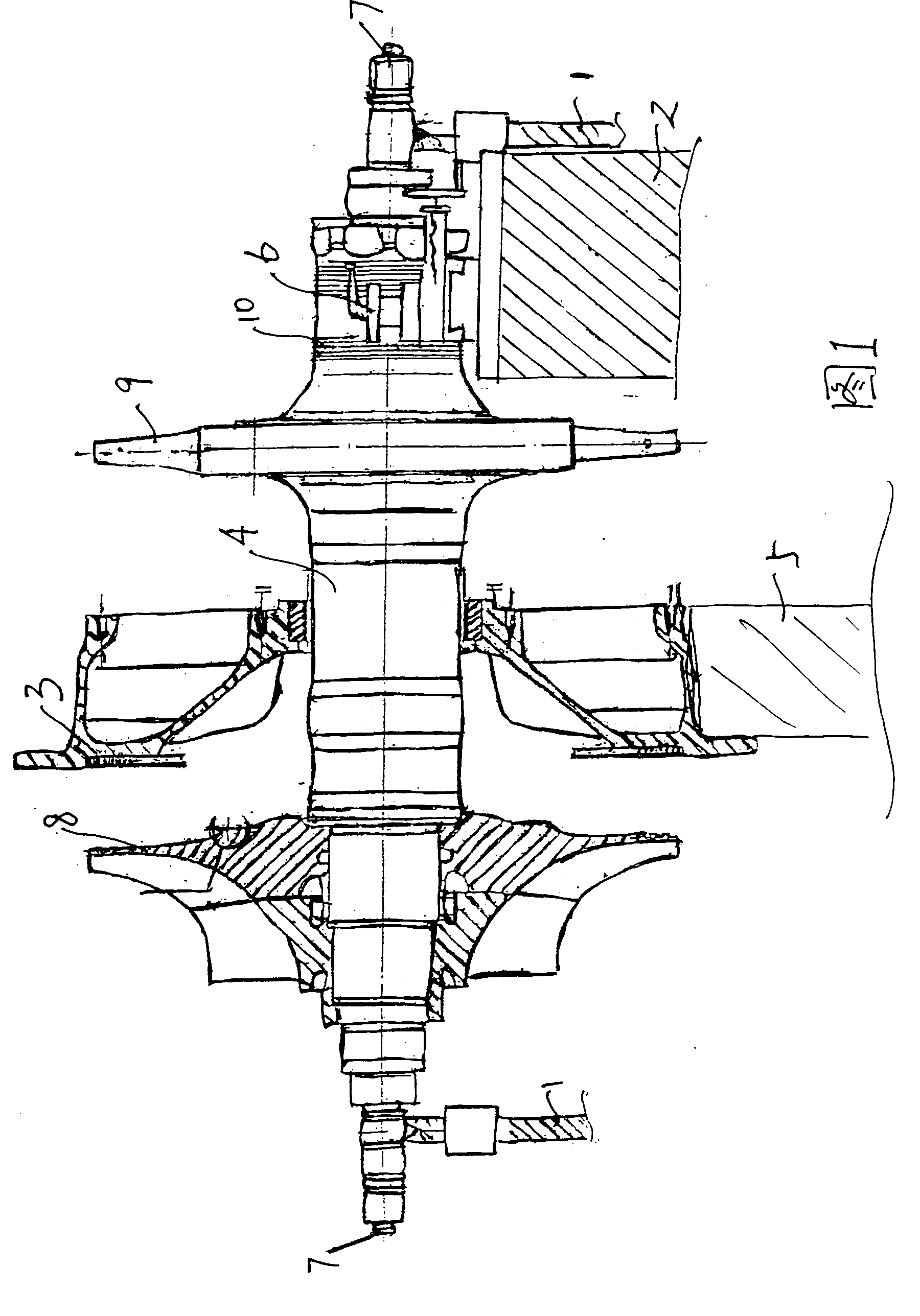

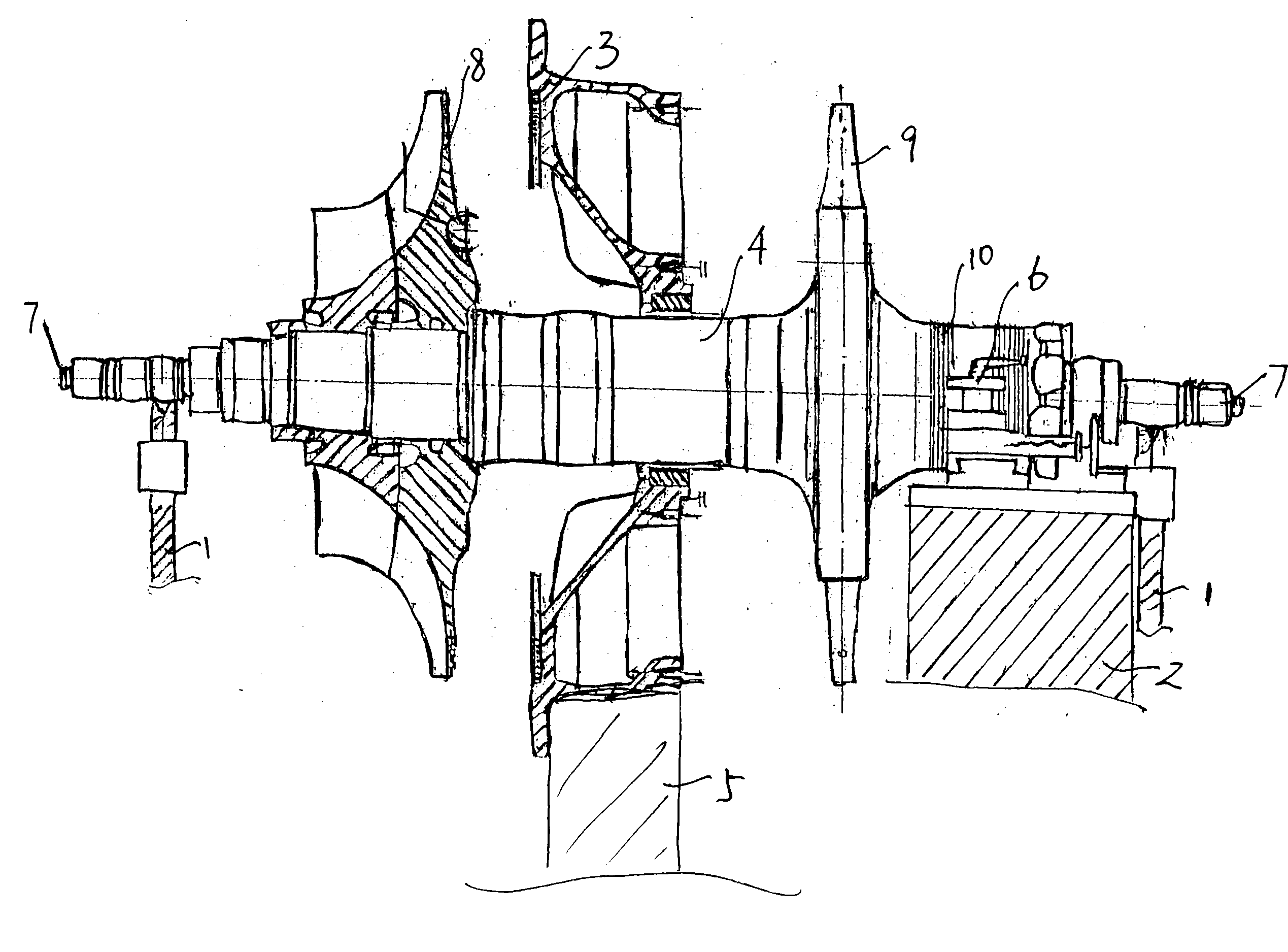

[0033] A method for cutting and processing rotors by using a dynamic balancing machine is a method for cutting and repairing diesel engine supercharger rotors, at least including processing one of the air seal, the shaft head, and the renewed exhaust gas vane; The processing of the seal includes the following steps:

[0034] (1) Adjust the roller frames of the two supporting points on the dynamic balancing machine to the same height, place the rotor of the diesel engine supercharger on the roller frames of the two supporting points of the dynamic balancing machine, and use the top frames at both ends of the rotor for the center holes at both ends of the dynamic balancing machine Hold it, and press the rotor tightly with the compression frame of the dynamic balancing machine, and use the ring belt of the dynamic balancing machine as a device to drive the rotor to rotate;

[0035] (2) At the exhaust gas end of the rotor shaft, between the exhaust gas impeller of the turbocharger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com