Method for forming orifice in a secondary shell of pressurized water reactor steam generator

A technology of steam generator and pressurized water reactor, which is applied in steam generation method, steam generation method using heat carrier, steam generation, etc., can solve difficult problems, can not be used to inspect or clean steam generator tube bundles, limited inspection area, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

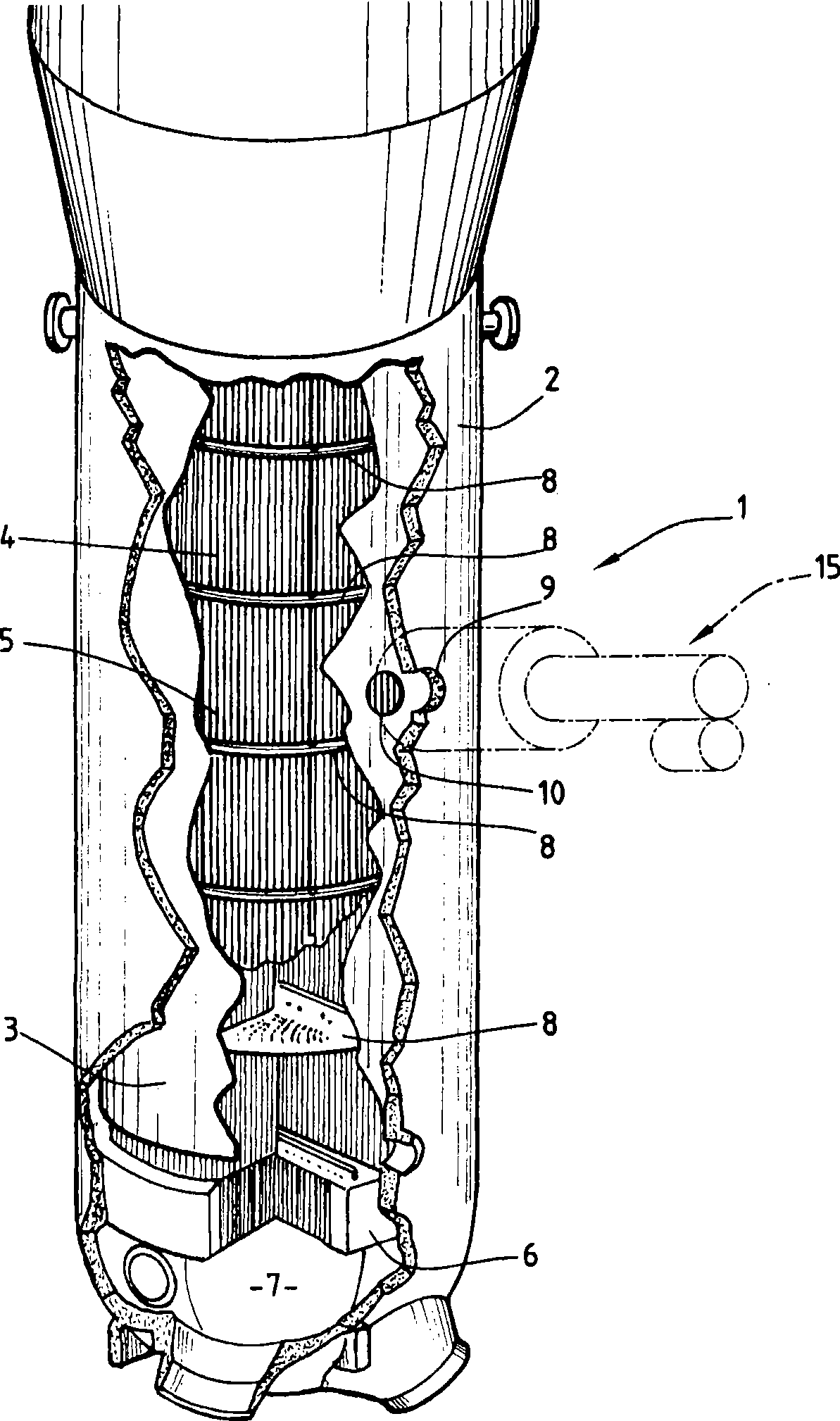

[0047] figure 1 The lower part of the pressurized water reactor steam generator, generally designated by reference numeral 1, is shown.

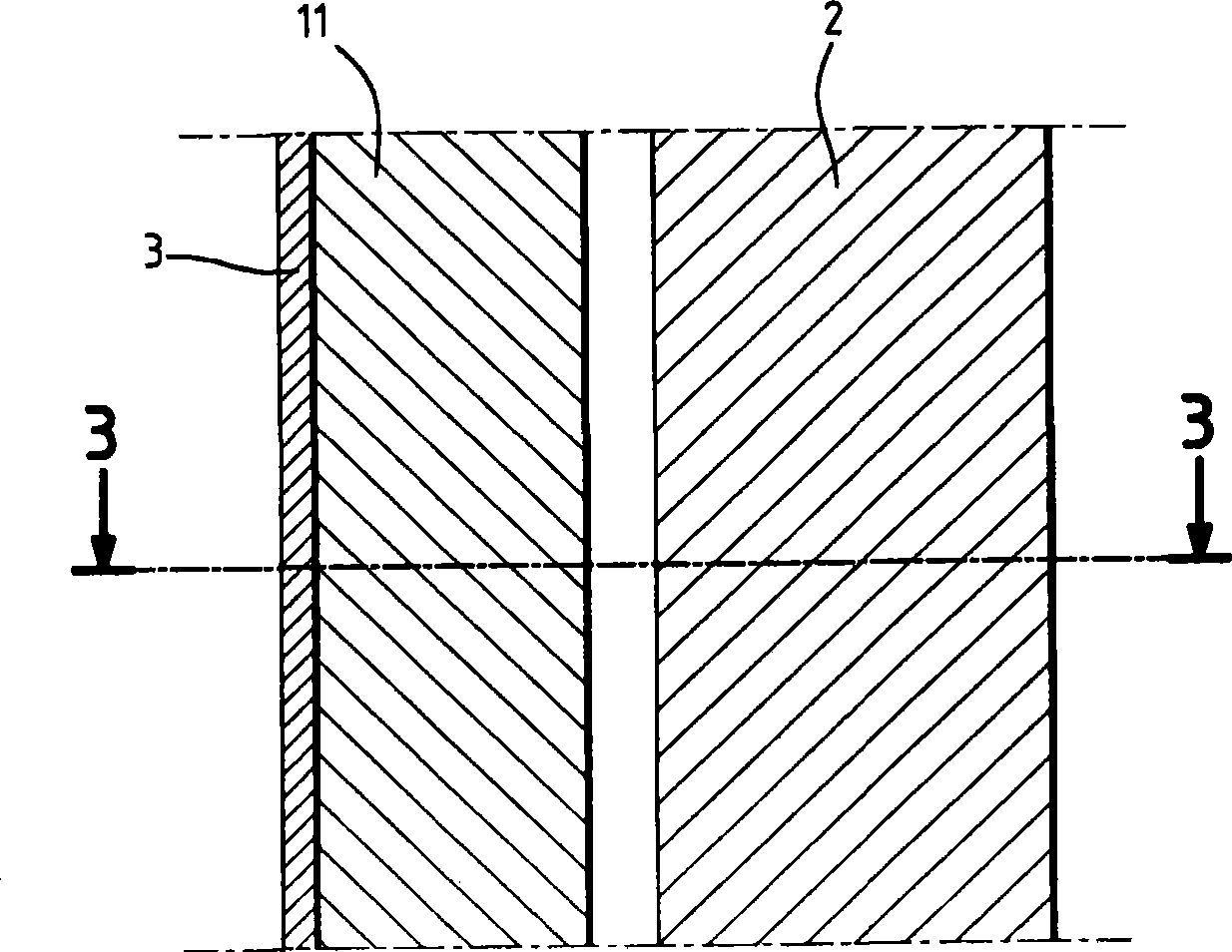

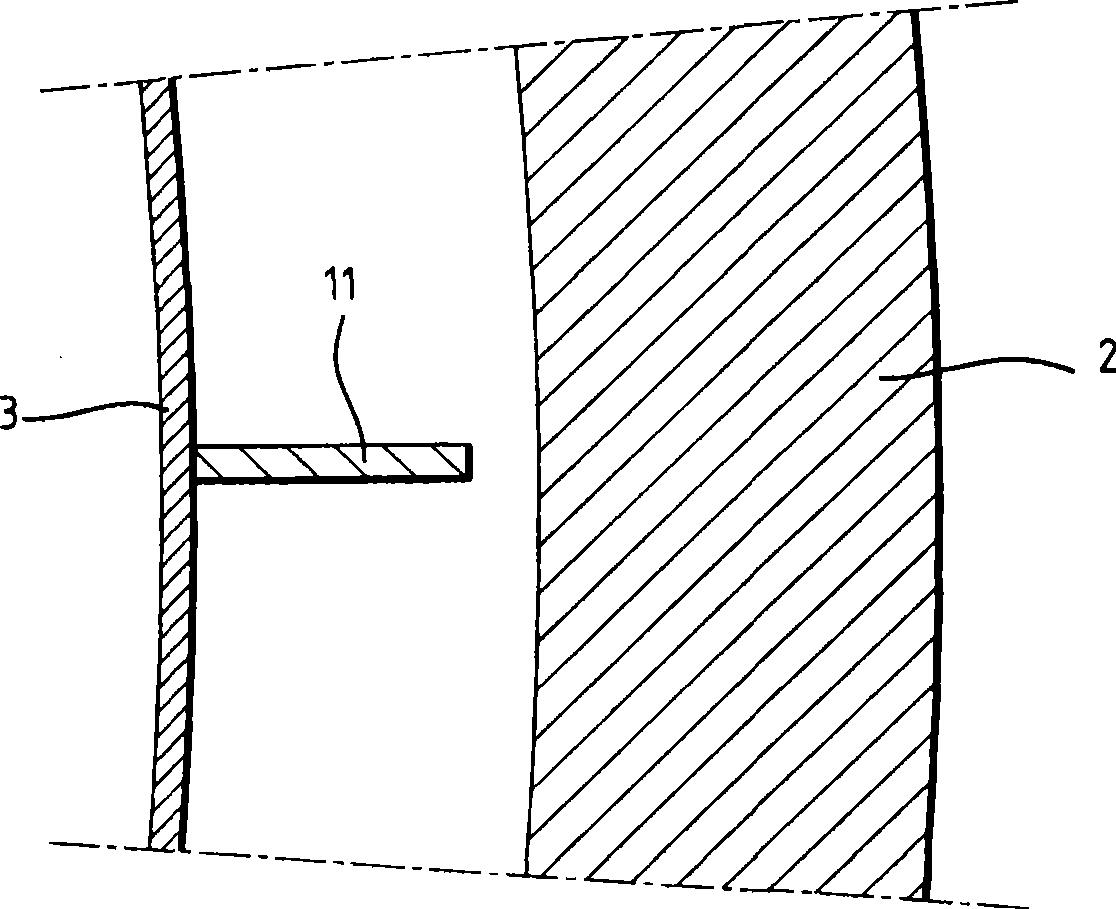

[0048] The steam generator 1 comprises, in a conventional manner, an essentially cylindrical pressure boundary 2 , inside which is coaxially positioned a tube bundle envelope 3 containing the tube bundles 4 of the steam generator 1 .

[0049] The tube bundle 4 consists of a large number of tubes 5 bent into a U-shape, each tube 5 comprising two straight branches which at their ends are connected to a tube sheet fixed to the lower part of the pressure boundary 2 of the steam generator 1 6 is engaged and fixed therein. The pressure boundary 2 is connected to a hemispherical end defining a tank 7 in two parts.

[0050] Inside the tube bundle envelope 3, at continuous positions along the height of the tube bundle, tube support plates 8 are fixed, and the tube support plates 8 are used to fix the branches of the tubes 5 in the bundle 4 in place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com