Polyester film for shrinkable cigarette pack

A technology for polyester film and packaging, applied in the field of polyester film, can solve problems such as dull color, whitening and fogging, and easy to be scratched, and achieve high expansion, good fragrance retention, and high glass transition temperature Effect

Active Publication Date: 2010-08-18

WEIFANG FUWEI PLASTIC

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the BOPP cigarette film whose core layer is mainly composed of polypropylene material and whose surface layer is mainly composed of ternary or binary random copolymerized polypropylene copolymer, due to the limitation of the properties of the main raw material, its gas barrier performance (flavor retention) properties), the surface gloss is not ideal, and the glass transition temperature of the surface material is lower than normal temperature, which makes it easy to be scratched during transportation and circulation, and even white and foggy in serious cases, resulting in unclear cigarette label patterns , The color is dull, this phenomenon is called grinding phenomenon

Especially in today's situation where tobacco products are generally not allowed to advertise and marketing restrictions are increasing, BOPP cigarette film can no longer meet the needs of cigarette packaging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

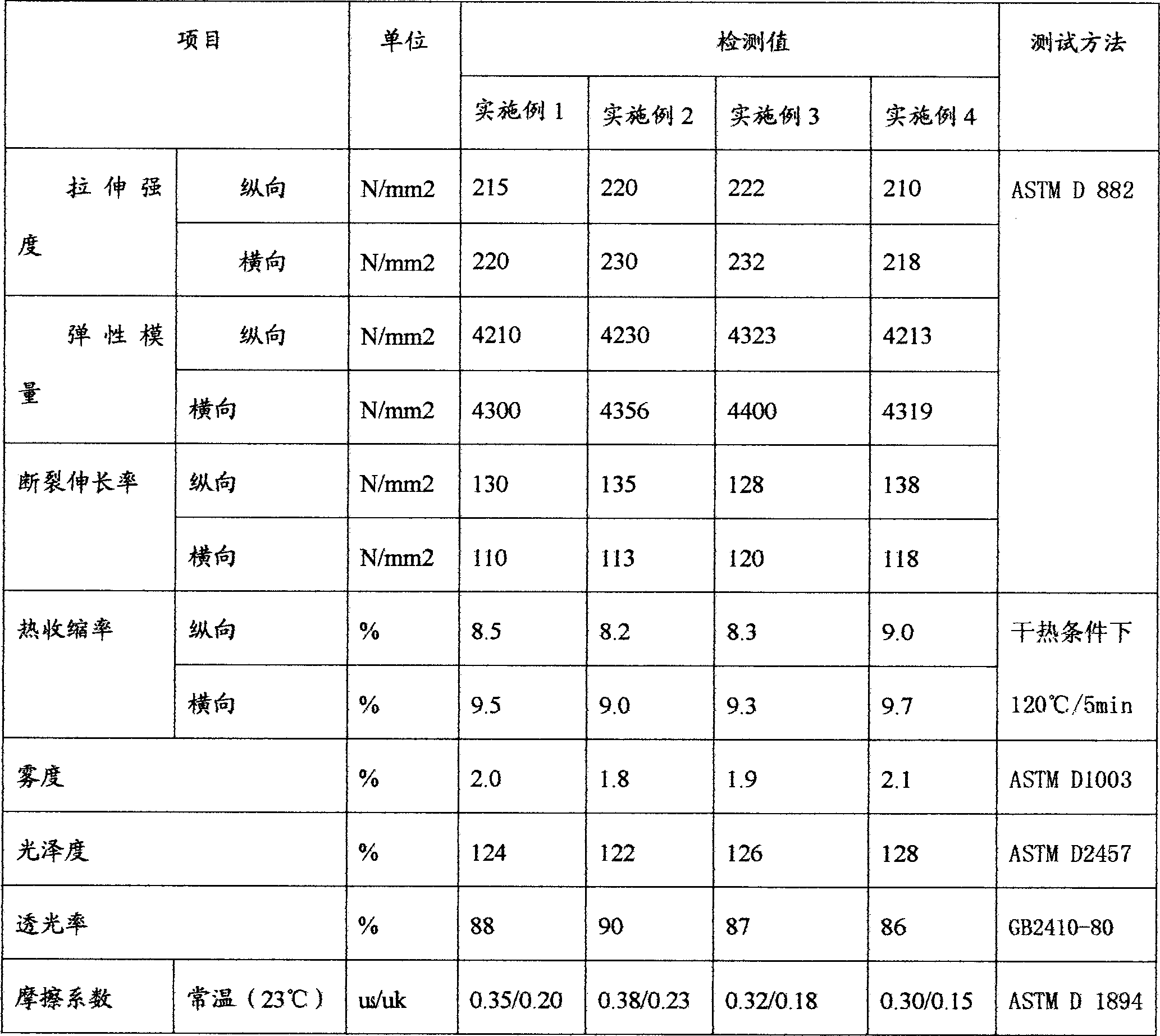

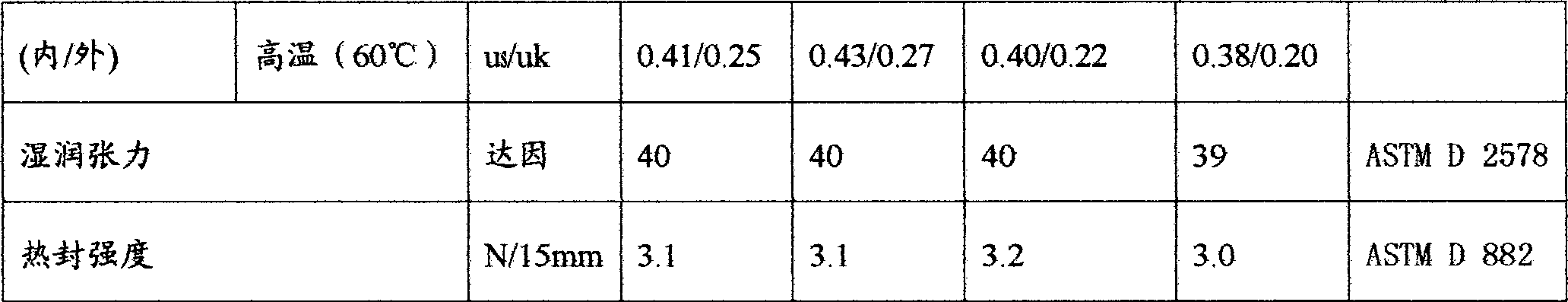

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a contracting type polyester film for packing cigarettes, which comprises three layered structures. The main composition of the upper surface layer of the layered structure is copolycondensation modified polyester; the main composition of the core layer of the layered structure is polyethylene glycol terephthalate; the main composition of the lower surface layer of the layered structure is copolycondensation modified polyester; the upper surface layer, the core layer and the lower surface layer are directly co-extruded and compounded. The polyester film has good fragrance protectiveness, and solves the problem that the BOPP cigarette film is not wear-resistant. Simultaneously, due to the high stiffness of the polyester film, a plurality of C5 or C9 petroresins is not required to be added as the stiffening agent in the core layer as the high contracting type cigarette film, therefore, the cost of the polyester film is nearly identical to that of the BOPP cigarette film, and the polyester film is particularly suitable for packing the cigarettes with stiff casement.

Description

Technical field The invention relates to the technical field of polyester film, in particular to a polyester film suitable for hard pack cigarettes. Background technique Cigarette packaging film is referred to as cigarette film. At present, small packs of hard box cigarettes on the market mainly use high-shrinkage biaxially oriented polypropylene film (BOPP cigarette film) with a thickness of 20-22um. It has low heat sealing temperature, uniform shrinkage, and Excellent smoothness, good optical properties, etc. meet the good machine performance and appearance requirements required in the cigarette packaging process. However, the BOPP smoke film whose core layer is made of polypropylene material and the surface layer is made of ternary or binary random copolymer polypropylene copolymer as the main body, due to the nature of the main raw material, its gas barrier performance (scent preservation) The surface gloss is not ideal, and the surface material is lower than the glass tra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D85/10B65D65/40B32B27/36B32B27/20C08L67/00C08L67/02C08K3/36C08K5/19C08L83/04C08L71/08

Inventor 吴德松孙文训靳钊彭宜海刘志强滕岩

Owner WEIFANG FUWEI PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com