Apparatus for preparing nanometer metal powder

A metal powder, nano-scale technology, applied in the direction of cells, etc., can solve the problems of unfavorable production process control, affecting collectors, unfavorable copper powder coalescence, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

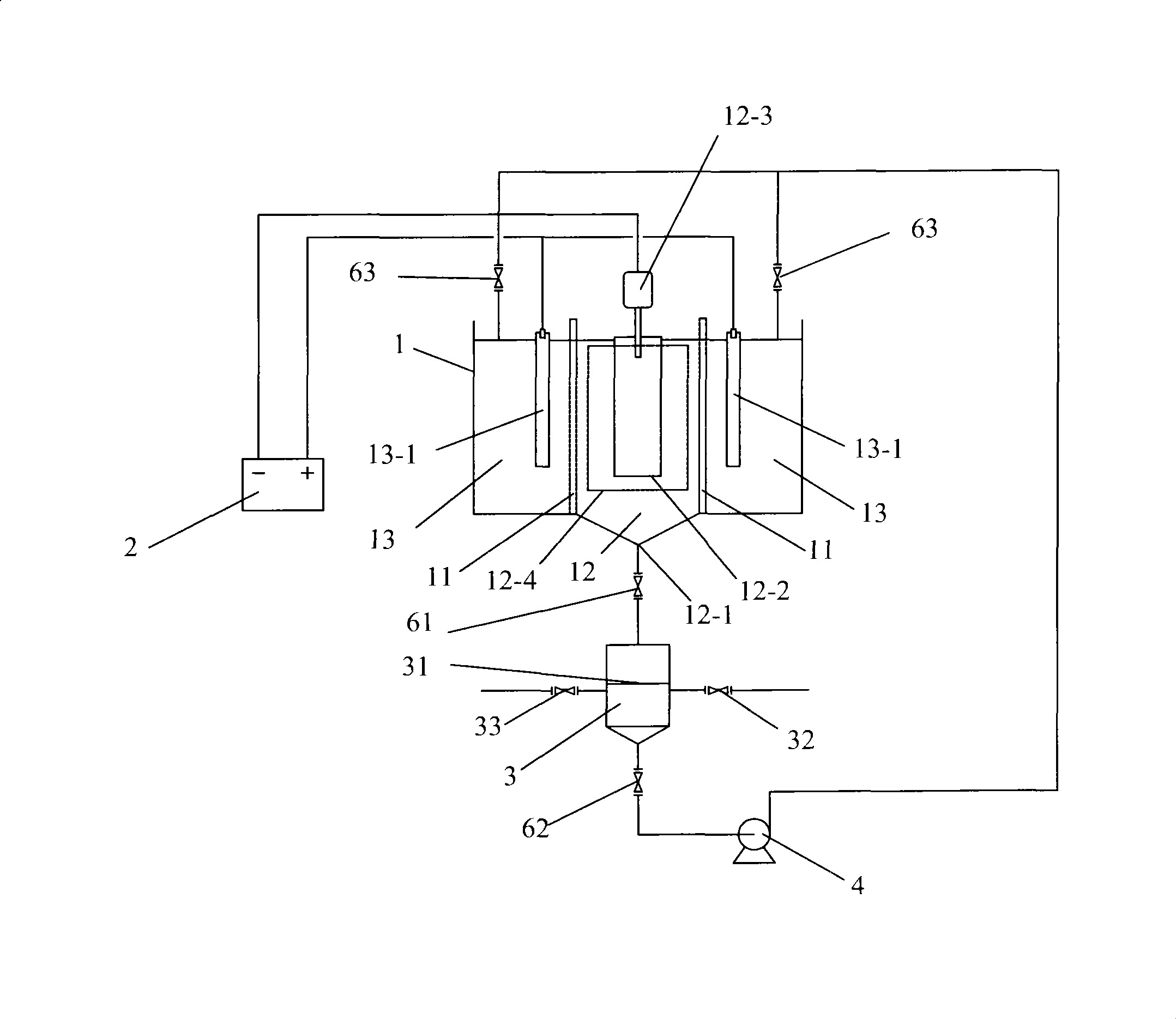

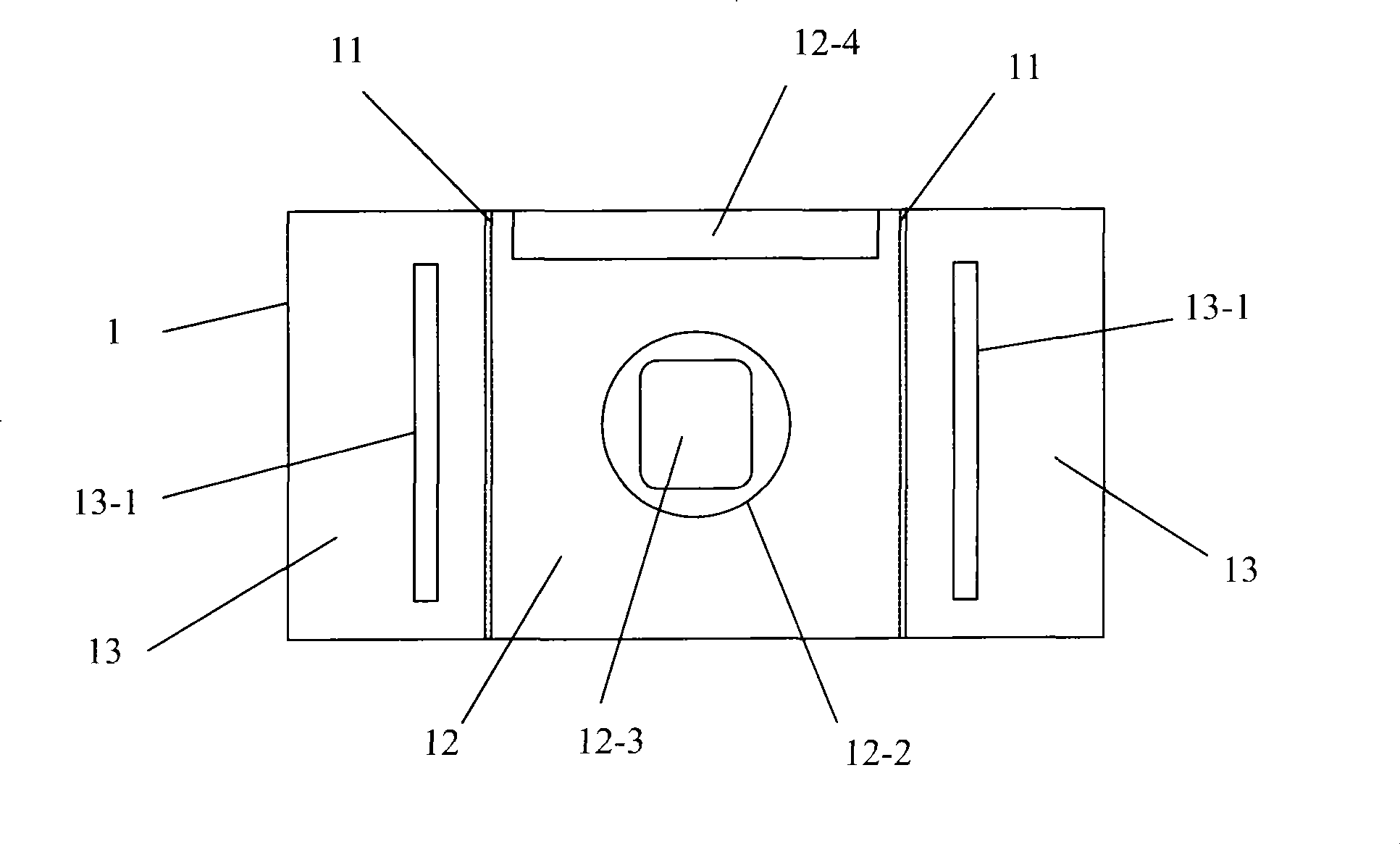

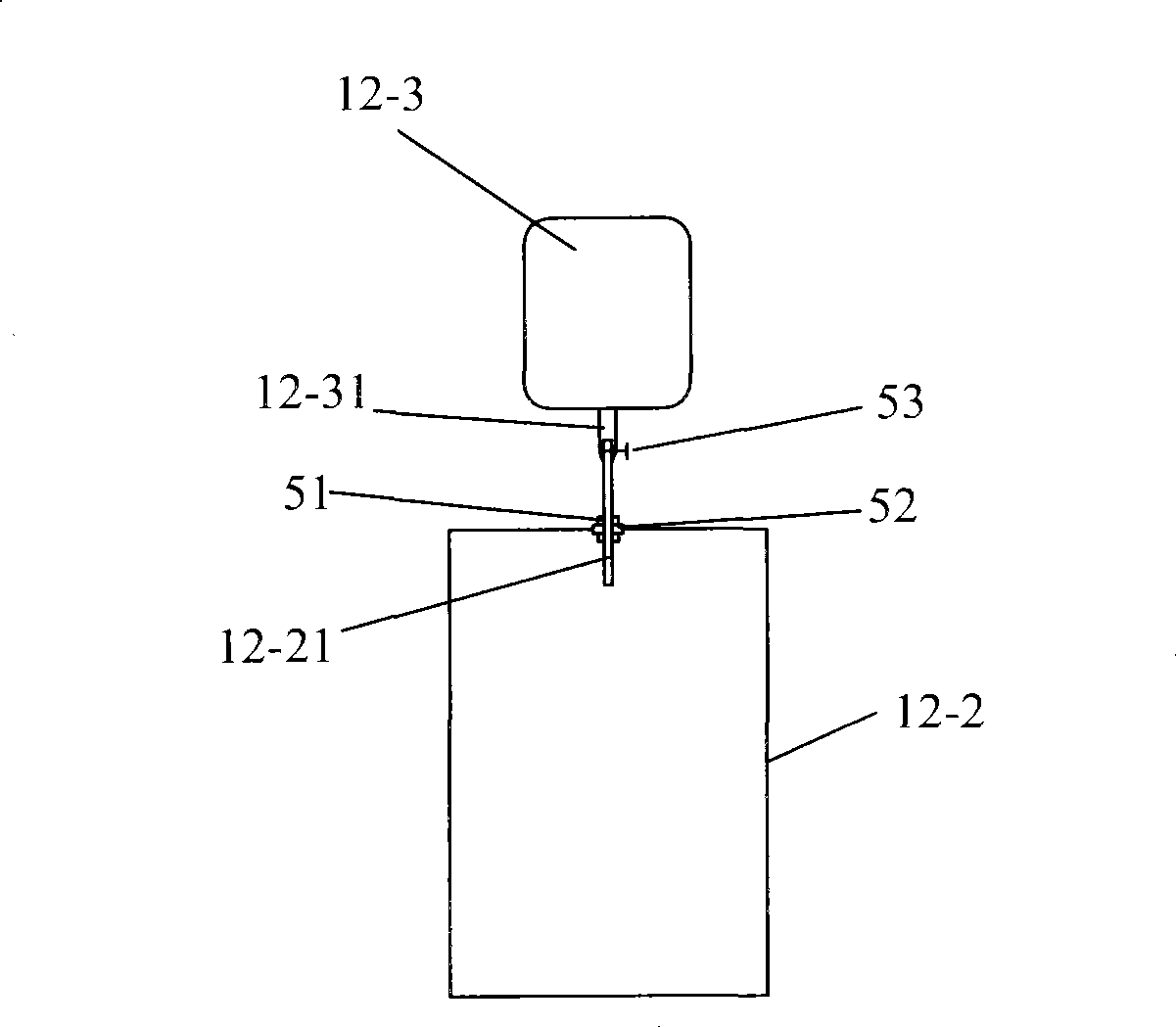

[0015] The device for continuously preparing nanoscale metal powder of the present invention includes an electrolytic tank 1 , a power supply 2 , a vacuum filter 3 and a circulation pump 4 .

[0016] The electrolytic cell 1 is divided into a cathode chamber 12 and two anode chambers 13 by two diaphragms 11 , and an anode 13 - 1 connected to the positive pole of the power supply 2 is arranged in the two anode chambers 13 . The anode 13-1 is a target metal or an anode basket containing target metals such as block or powder.

[0017] The bottom of the cathode chamber 12 is funnel-shaped, and is provided with a discharge hole 12 - 1 , and the discharge hole 12 - 1 is connected to the vacuum filter 3 through a pipeline provided with a discharge valve 61 . The lower end of the vacuum filter 3 is connected to the circulation pump 4 through a pipeline provided with a drain valve 62 . The circulation pump 4 is respectively connected to the two anode chambers 13 of the electrolytic cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com