Light source assembly high-power LED lamp and installation method thereof in lamp holder

A technology of LED lamps and LED light sources, which is applied in the direction of light sources, point light sources, semiconductor devices of light-emitting elements, etc., can solve the problems of screw or upper heat dissipation glue connection is not firm, easy to loose or even fall off the installation efficiency, to avoid the installation of screws Or the inconvenience of applying heat dissipation glue, and the effect of overcoming the weak connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment;

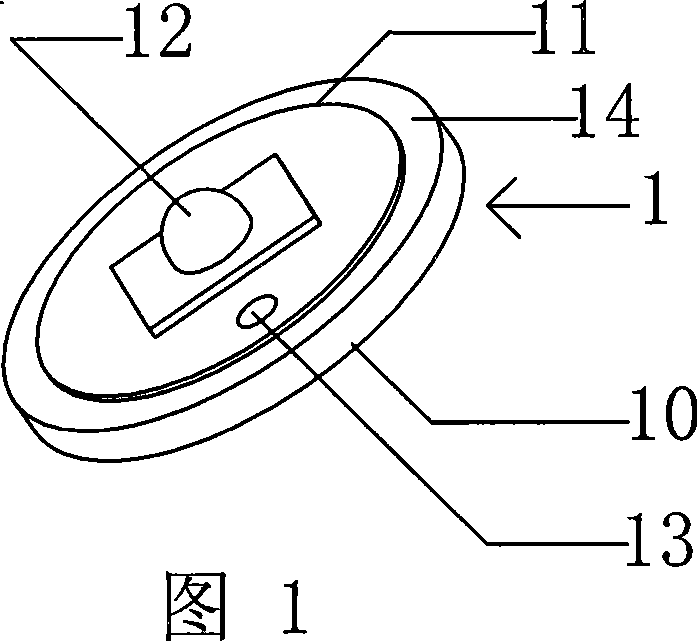

[0026] Please refer to Fig. 1; it is the high-power LED light source assembly 1 of the present invention. The light source assembly 1 uses a circular aluminum substrate with very good thermal conductivity as the heat conduction plate 10. The thickness of the heat conduction plate 10 is preferably between 5 and 10 mm. , a PCB circuit board 11 with the same shape as the aluminum-based heat-conducting plate 10 but slightly smaller than the aluminum-based heat-conducting plate 10 is packaged on the middle surface of the aluminum-based heat-conducting plate 10, so that an uncoated PCB circuit board is formed around the aluminum-based heat-conducting plate 10 11 covered aluminum base ring 14 . One or more high-power LEDs 12 are welded on the PCB circuit board 11 to form an electrical connection, and two external positive and negative power supply wires are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap