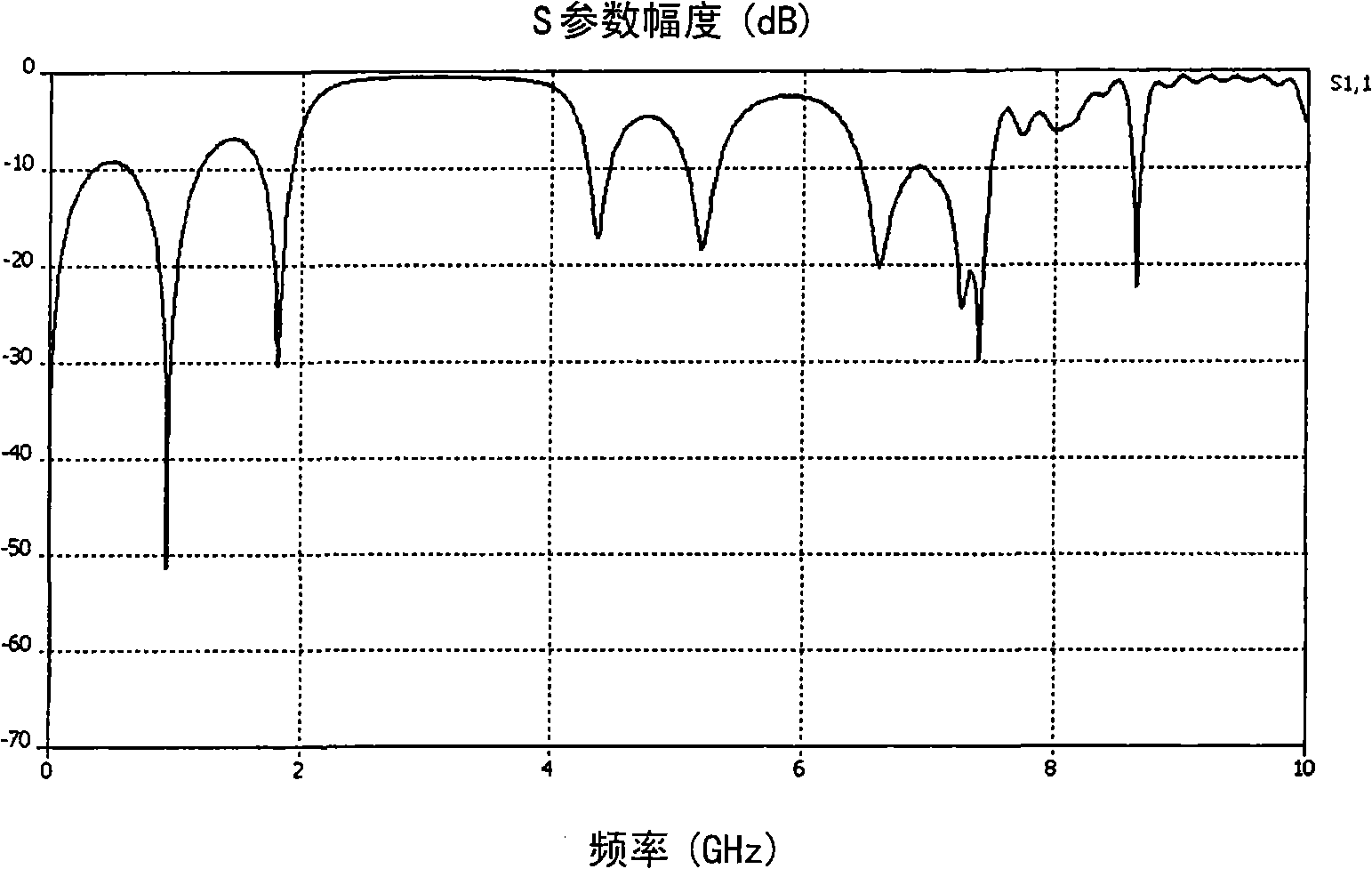

Multiband antenna using photonic band gap material

A technology of photonic bandgap materials and multi-band antennas, which is applied to antennas, antenna parts, waveguide devices, etc., can solve the problems of large basic size and limit the application of PBG, and achieve the effect of simple structure and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

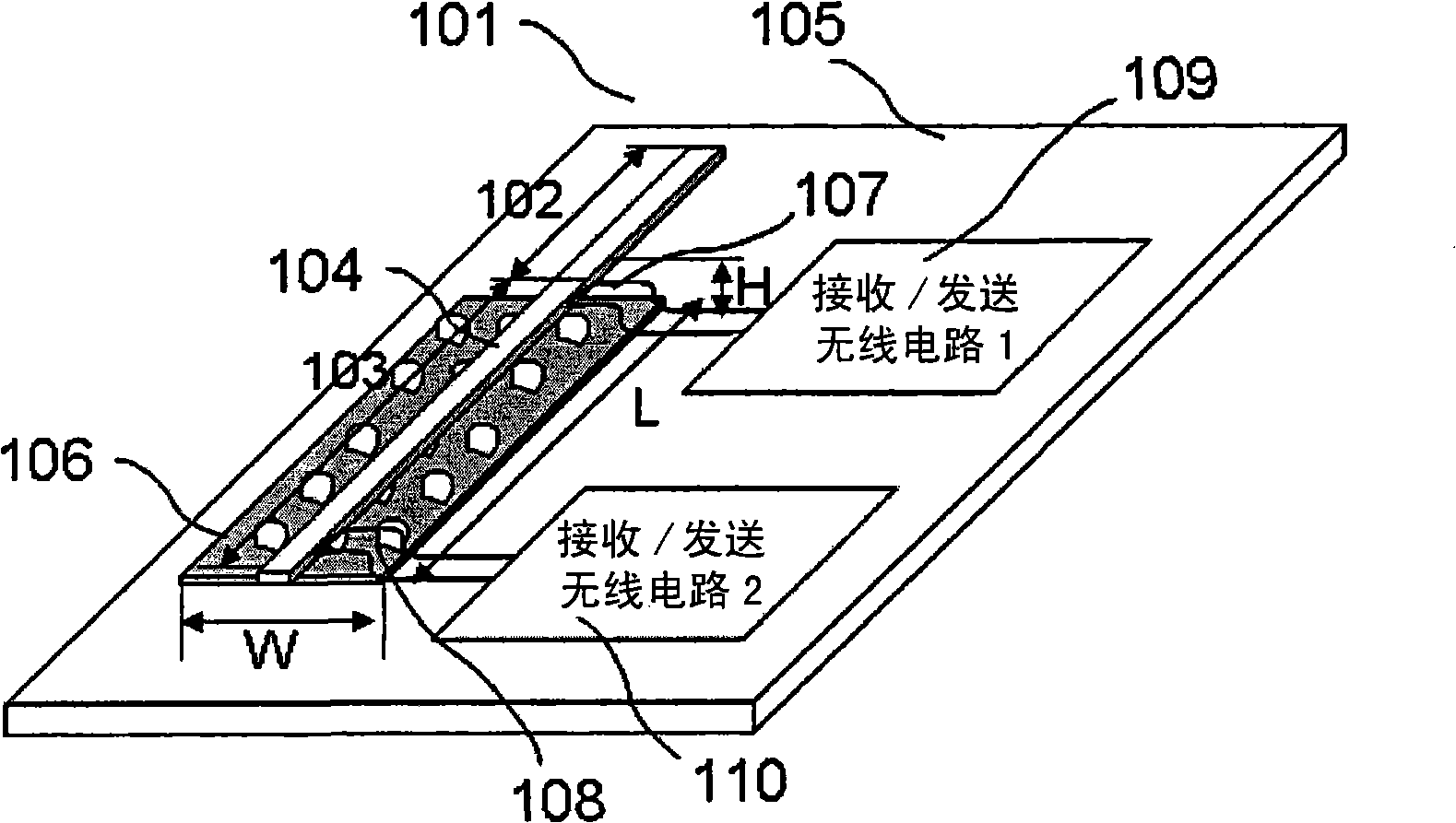

[0022] Refer below figure 2 A first embodiment of the structure of a multiband antenna using a photonic bandgap material is described. Such as figure 2 As shown, the antenna device according to this embodiment includes a microstrip antenna 104, a substrate 105, a photonic bandgap material plate 106, a first feed line 107, a second feed line 108, a first receiving / transmitting wireless circuit 109, a second electric circuit Receive / transmit wireless circuit 110.

[0023] In the antenna device 101 of this embodiment, the photonic bandgap material plate 106 is disposed on the substrate 105 and is in close contact with the substrate 105 . The microstrip antenna 104 is disposed on the photonic bandgap material plate 106 along the length direction of the photonic bandgap material plate 106 , that is, the length direction of the microstrip antenna 104 is the same as that of the photonic bandgap material plate 106 . The length of the microstrip antenna 104 is longer than the leng...

no. 2 example

[0036] In the first embodiment, the PBG material is used to be in close contact with the second antenna unit 103 to realize reception / transmission of multi-band signals.

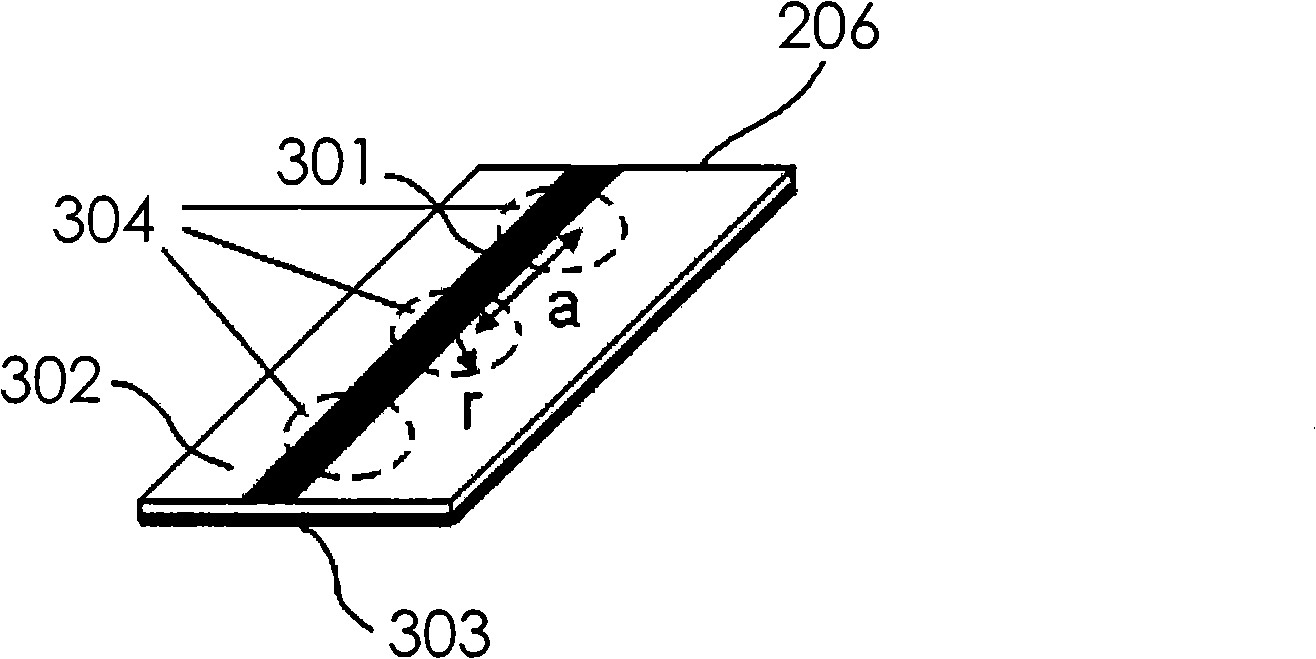

[0037] Since the use of PBG materials will increase the cost of the antenna, sometimes PBG materials cannot be used to realize the multi-band antenna due to cost considerations. A second embodiment of the present invention provides a multi-band antenna device obtained by processing a printed circuit board to realize a PBG configuration. The cost of the multi-band antenna device according to the second embodiment is very low, even negligible.

[0038] In the prior art, it is proposed to process a periodic structure on a printed circuit board to realize a PBG structure. image 3 A schematic structural diagram of a PBG structure according to the second embodiment of the present invention is shown. Such as image 3 As shown, the PBG structure used in the second embodiment includes a microstrip antenna 204 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com