Preparation method for oil solution containing black jack pigment

A caramel coloring, oil solution technology, applied in food preparation, application, food science and other directions, can solve the problems of inaccurate explanation of caramel reaction, unpredictable complexity, and can only be used as a water-soluble food additive, etc. The effect of saving food, saving energy and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

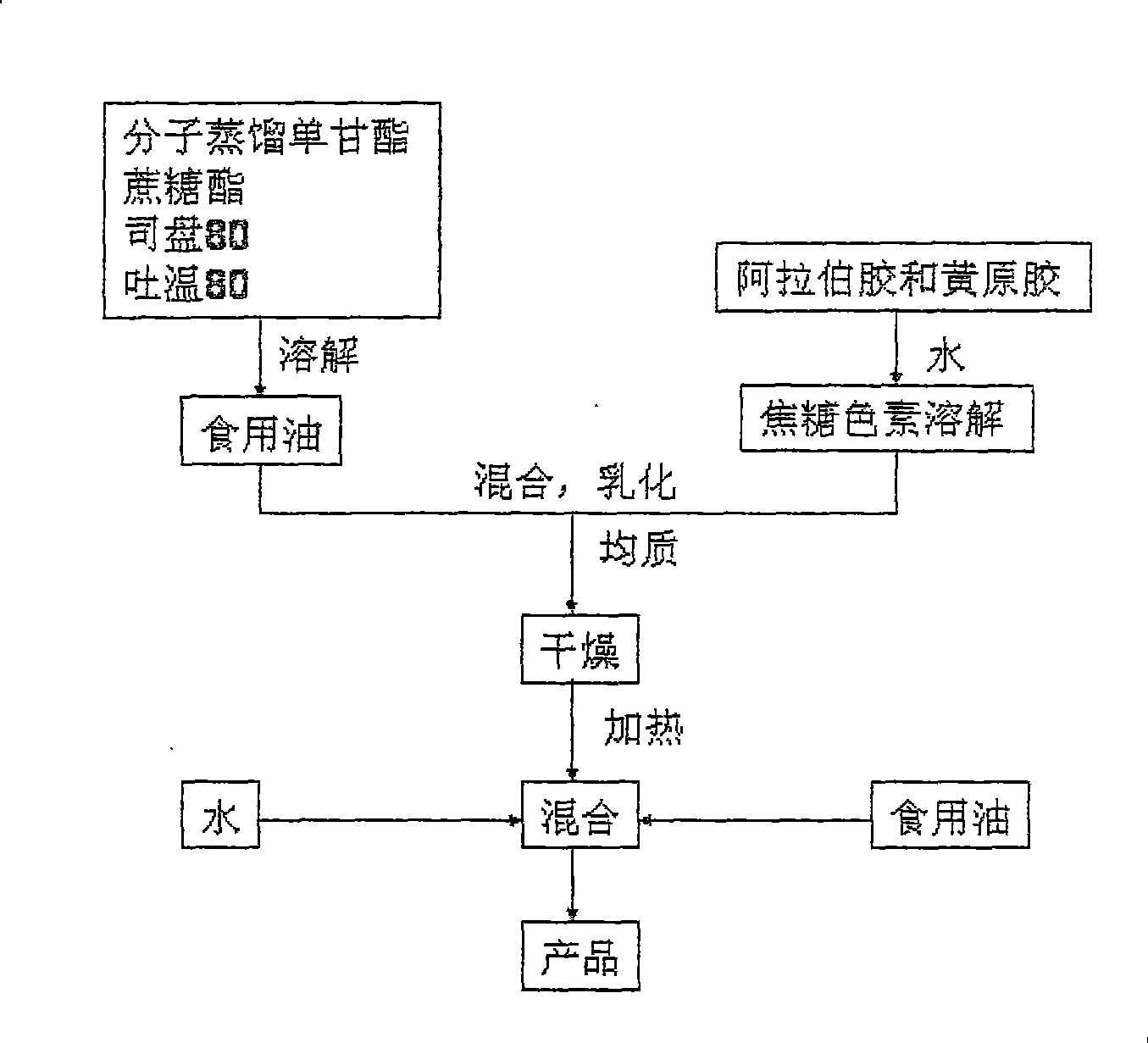

[0034] The first step is to prepare oil-soluble powder containing caramel coloring

[0035] Weighing according to weight percentage: caramel pigment 18%, unsaturated molecular distillation monoglyceride 23%, sucrose ester 8%, Span 80: 8%, Tween 80: 8%, soybean oil 18%, gum arabic 8% , xanthan gum 9%, a total of 300 grams.

[0036] Swell the Arabic gum and xanthan gum with double the weight of cold water, heat to 80°C the next day, dissolve the weighed caramel pigment in the colloid solution, keep the temperature of 65°C for 50 minutes, and filter to remove the insoluble Keep the temperature of 55°C for later use.

[0037] Then prepare the emulsifier oil solution: weigh the unsaturated molecule distilled monoglyceride, sucrose ester, Span 80, and Tween 80, dissolve it in edible oil, and heat it to 78°C until the emulsifier is completely dissolved.

[0038] Keep the temperature of the upper oil and water, add the emulsifier oil solution to the caramel pigment colloid solution,...

Embodiment 2

[0042] The first step is to prepare oil-soluble powder containing caramel coloring

[0043] Weighing according to weight percentage: caramel pigment 10%, unsaturated molecular distillation monoglyceride 10%, sucrose ester 12%, Span 80: 9%, Tween 80: 9%, peanut oil 30%, gum arabic 10%, Xanthan Gum 10%, total 300g.

[0044] Swell Arabic gum and xanthan gum with twice the weight of cold water, heat to 70°C the next day, dissolve the weighed caramel pigment in the colloid solution, keep the temperature of 65°C for 30 minutes, filter to remove insoluble Keep the temperature at 50°C for later use.

[0045] Then prepare the emulsifier oil solution: weigh the unsaturated molecule distilled monoglyceride, sucrose ester, Span 80, and Tween 80, dissolve it in peanut oil, and heat it to 70°C until the emulsifier is completely dissolved.

[0046]Keep the temperature of the upper oil and water, add the emulsifier oil solution to the caramel pigment colloid solution, stir, emulsify, 30 min...

Embodiment 3

[0050] The first step is to prepare oil-soluble powder containing caramel coloring

[0051] Weighing according to weight percentage: caramel pigment 12%, unsaturated molecular distillation monoglyceride 27%, sucrose ester 7%, Span 80: 8%, Tween 80: 8%, peanut oil 25%, gum arabic 6%, Xanthan gum 7%, total 300g.

[0052] Swell Arabic gum and xanthan gum with twice the weight of cold water, heat to 70°C the next day, dissolve the weighed caramel pigment in the colloid solution, keep the temperature of 65°C for 30 minutes, filter to remove insoluble Keep the temperature at 50°C for later use.

[0053] Then prepare the emulsifier oil solution: weigh the unsaturated molecule distilled monoglyceride, sucrose ester, Span 80, and Tween 80, dissolve it in peanut oil, and heat it to 70°C until the emulsifier is completely dissolved.

[0054] Keep the temperature of the upper oil and water, add the emulsifier oil solution to the caramel pigment colloid solution, stir, emulsify, 30 minut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap