Preparation method for low poly-cationic surfactant

A technology of surfactants and polycations, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of cumbersome steps, long reaction cycle, low yield, etc., and achieve good application prospects, high viscosity, The effect of overcoming the chromatographic separation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

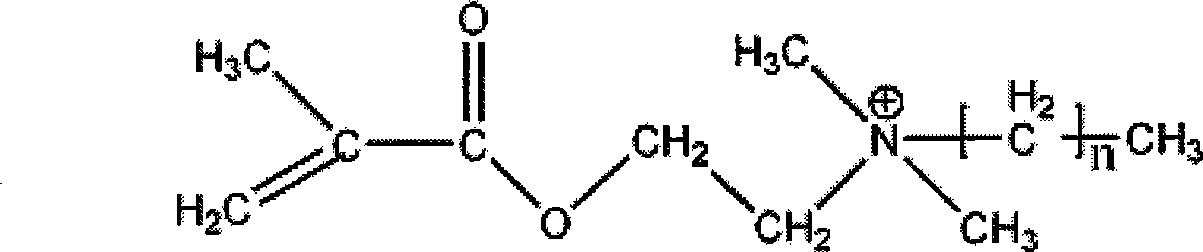

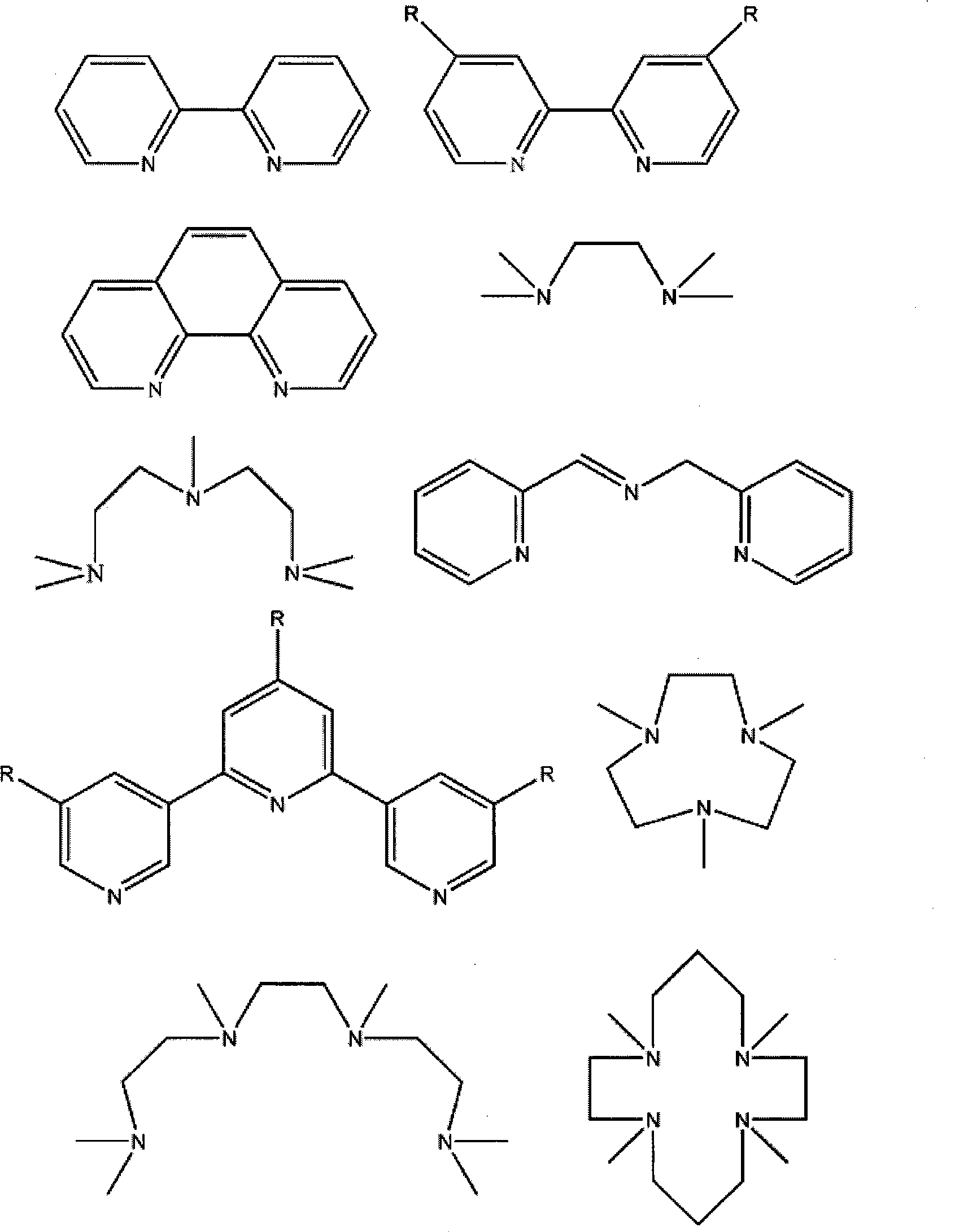

[0027] Weigh 6.5 grams of DM12 and 0.43 grams of ethyl 2-bromo-2-methylpropionate, put them into 50 ml of a mixed solution of isopropanol and water with a weight ratio of 1:1, stir to dissolve them, and wait until the dissolution is complete Nitrogen gas was passed in for 60 minutes while stirring constantly. Under nitrogen protection, 0.2 g of CuCl and 0.47 g of bipyridine were added and stirred continuously for 3 hours to stop the reaction.

Embodiment 2

[0029] Weigh 6.5 grams of DM12 and 0.43 grams of ethyl 2-bromo-2-methylpropionate, put them into 50 ml of a mixed solution of n-propanol and water with a weight ratio of 1:1, stir to dissolve them, and wait until the dissolution is complete Nitrogen gas was passed through for 30 minutes while stirring constantly. Under nitrogen protection, 0.2 g of CuCl and 0.47 g of bipyridine were added and stirred continuously for 4 hours to stop the reaction.

Embodiment 3

[0031] Weigh 6.5 grams of DM12 and 0.33 grams of methyl 2-bromo-2-methylpropionate, put them into 50 ml of ethanol and water mixed solution with a weight ratio of 2:1, stir to dissolve them, and pass Infuse nitrogen for 40 minutes, stirring constantly. Under the protection of nitrogen, 0.26 g of CuBr and 0.47 g of bipyridine were added, and the mixture was stirred continuously for 5 hours to stop the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com