Automatic application product line for shock absorption noise silencing slice

A coating line and sound-absorbing film technology, which is applied to the surface coating liquid device, coating, door/window accessories, etc., can solve the problems of uneven product quality, poor coating quality, and backward coating technology, etc. problems, to achieve good coating quality, improve performance and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

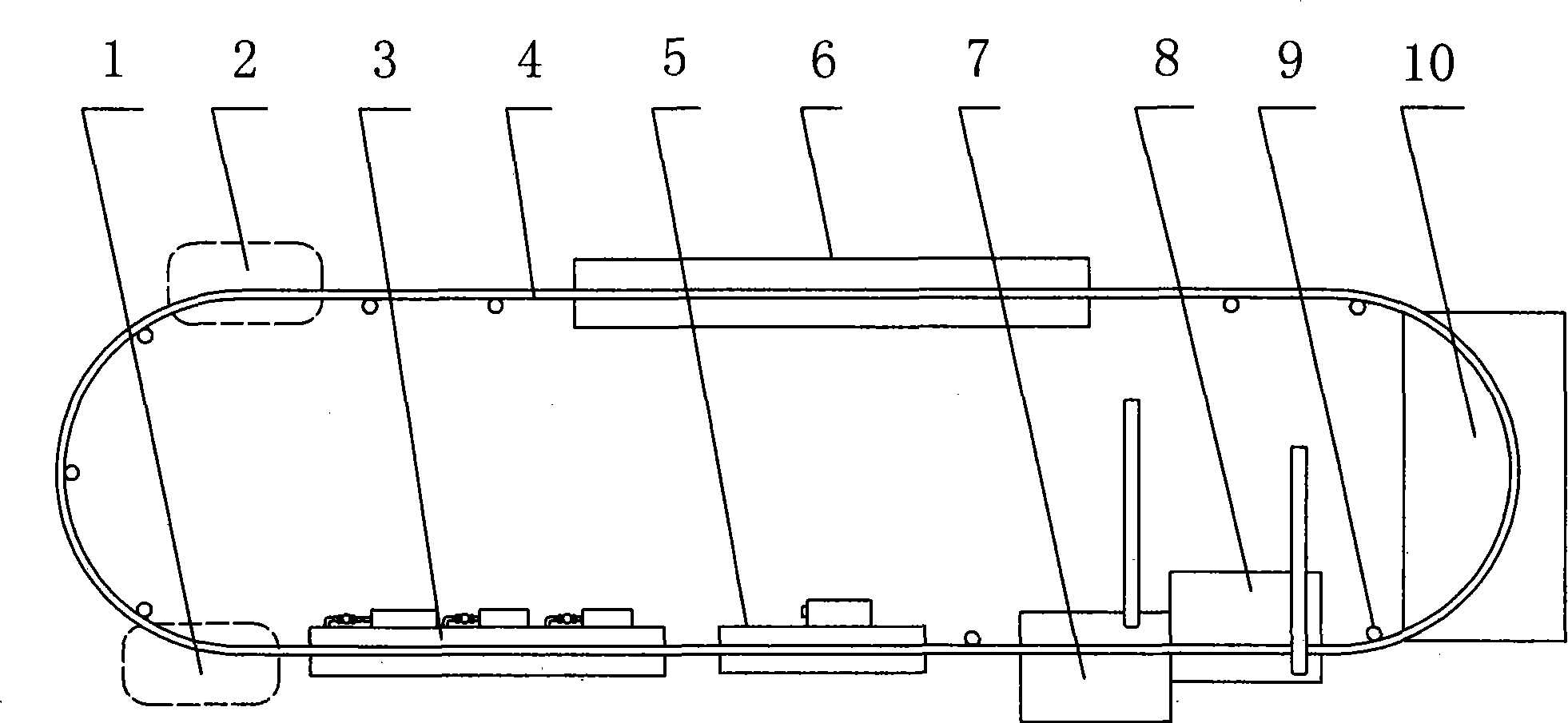

[0028] figure 1 is a top view of a preferred embodiment of the present invention. The coating line of this shock-absorbing and sound-absorbing sheet mainly consists of a conveying track 4 and a column 9. On the ground below the conveying track 4, there are hanging plate place 1, cleaning machine 3, drying room 5, iron plate front painting room 7, iron plate back painting room 8, leveling room 10, high temperature curing furnace 6, and take The board consists of 2 components.

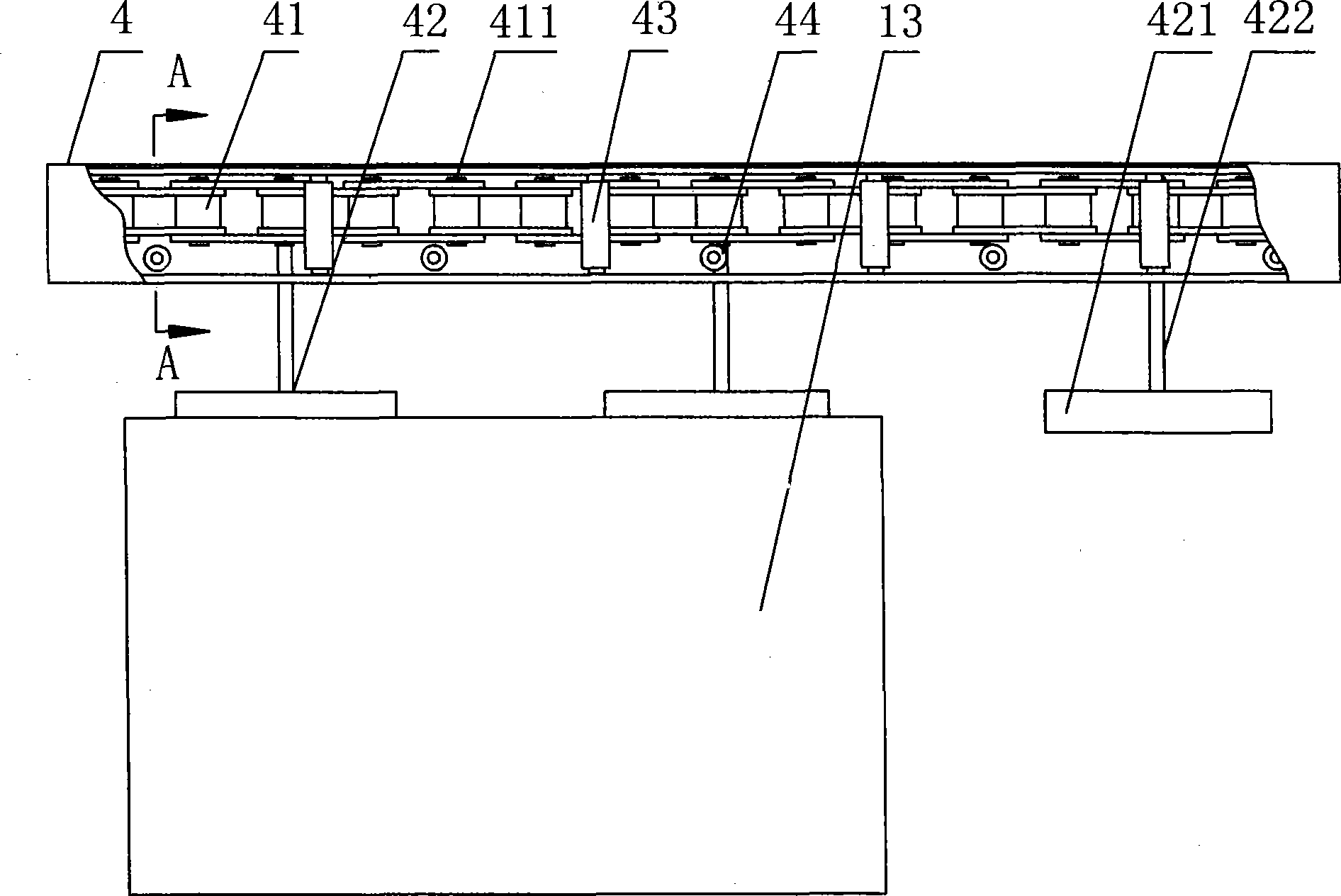

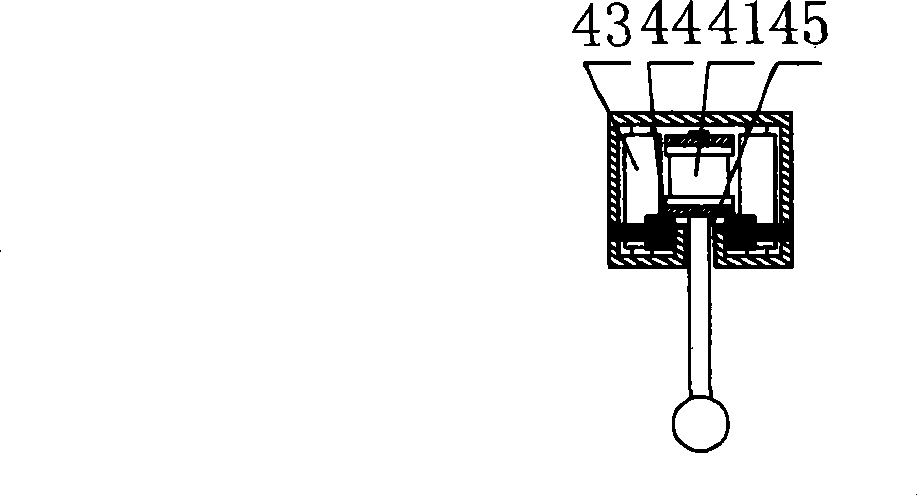

[0029] figure 2 It is a schematic diagram of a preferred structure of the conveying track 4 . A chain 41 is nested in the conveying track 4, and some magnetic hangers 42 are evenly and equidistantly fixed on the chain 41. The magnetic hangers 42 include a hanger 422 and a high-temperature-resistant magnet (permanent magnet) 421. The bottom of the bar 422 and the top of the hanging rod are connected with the round pin 411 of the chain, or directly replace the round pin 411 and are locked in the round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com