Simulation device for simulating conticaster double-cooling nozzle cooling performance

A simulation device and cooling effect technology, applied in computer control, instrument, control/adjustment system, etc., can solve the problems that the system cannot be simulated accurately, the position of the nozzle and the slab cannot be simulated, and the cooling characteristics of multiple rows of nozzles cannot be simulated, etc. Achieve the effect of high-precision simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

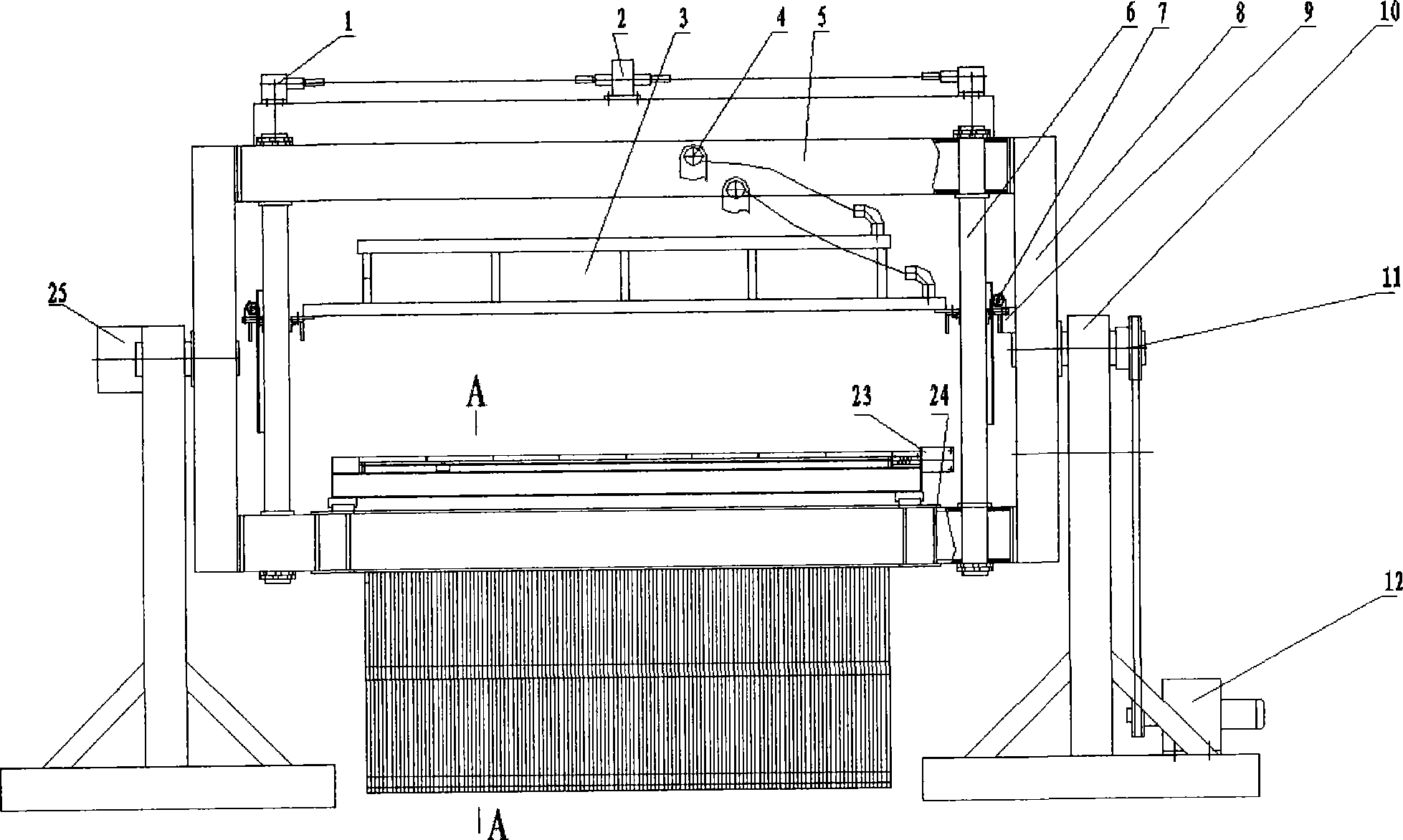

[0016] Embodiment 1: Simulation of the cooling effect of the segment nozzle

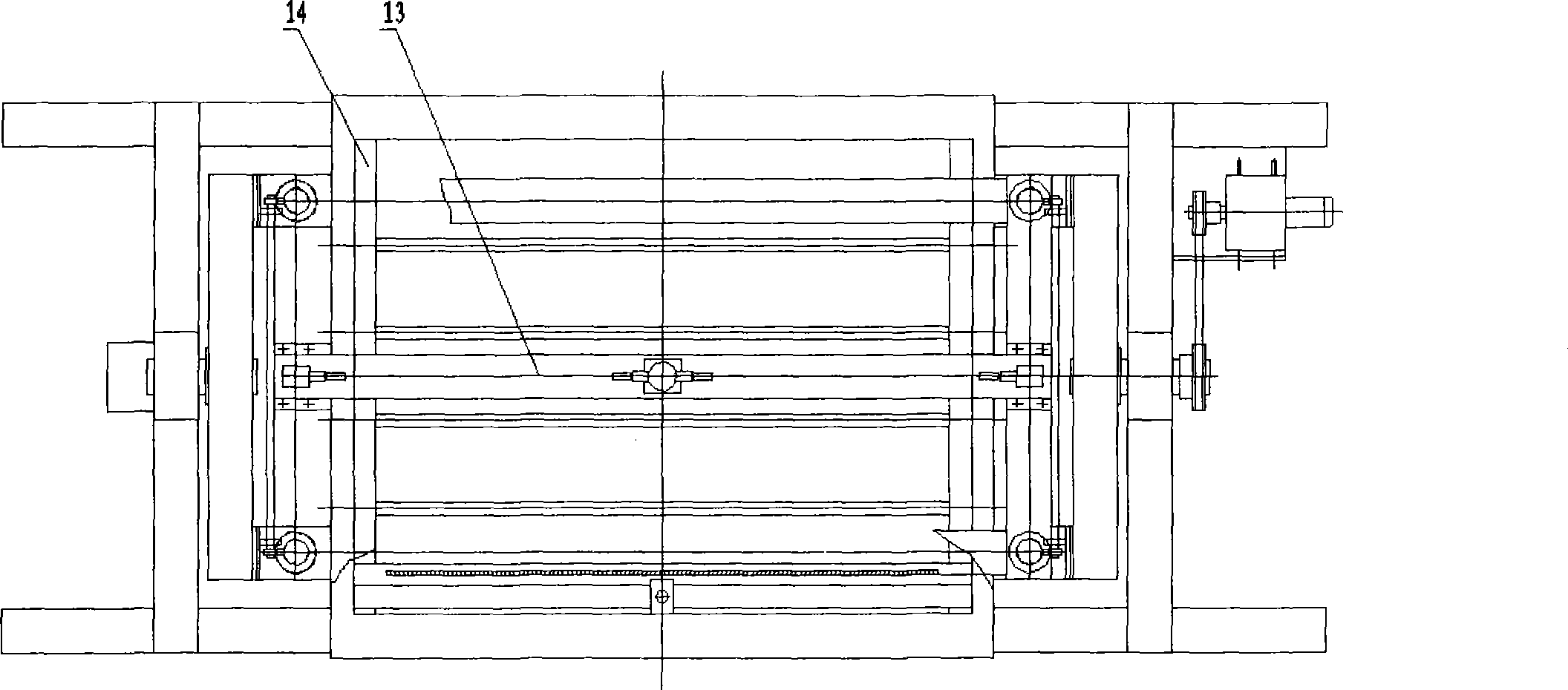

[0017] (1) According to the prototype of the simulated object, the nozzles are installed on the cold-state measurement and control frame of the simulation device, and 5 rows can be installed at the same time, and 6 nozzles can be installed in each row.

[0018] (2) Connect the water source and air source, and set the pressure and flow of water and air according to the parameters of the prototype.

[0019] (3) Open the air and water valves.

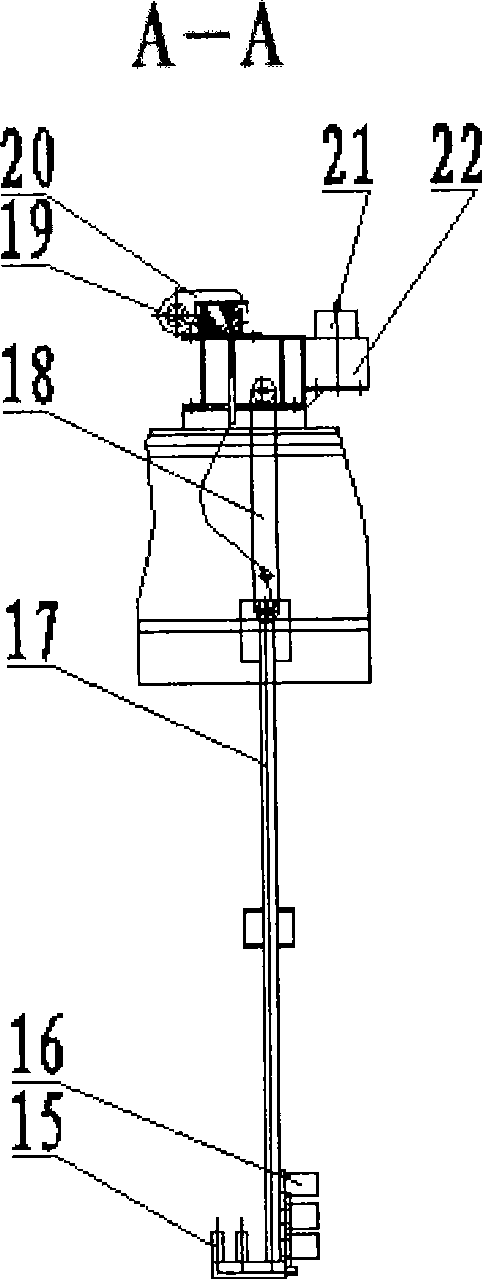

[0020] (4) Use the rotary reducer and the transmission sprocket chain to move the flow distribution and impact force receiving part.

[0021] (5) Rotate the water collector to 45°.

[0022] (6) Start the computer control system to measure the water flow distribution and impact force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com