A simulink modeling method for the mechanical hydraulic device of an aero-engine fuel regulator

A technology for aero-engines and fuel regulators, applied in design optimization/simulation, etc., can solve the problems of simulation calculation speed not as good as Simulink, complex double-layer nested algebraic loops, etc., achieve convenient parameter modification, increase simulation speed, and improve simulation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing.

[0060] A Simulink modeling method for the mechanical hydraulic device of an aero-engine fuel regulator, comprising the following steps:

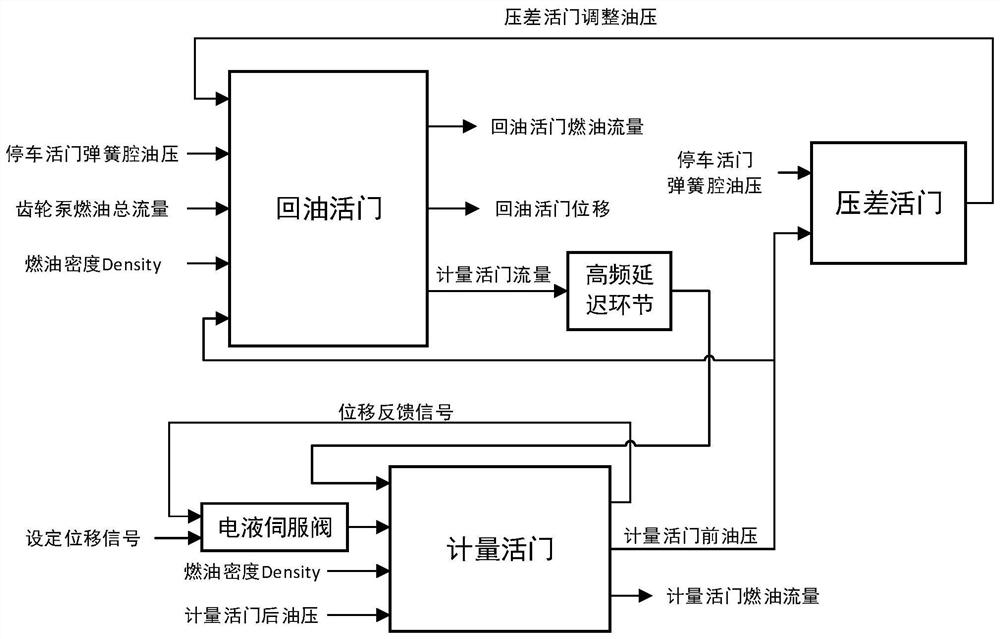

[0061] S1. Using the analytical method, model the main pressure difference control loop in the mechanical hydraulic device of the engine fuel control system. The main pressure difference control loop includes the metering valve, the oil return valve and the pressure difference valve;

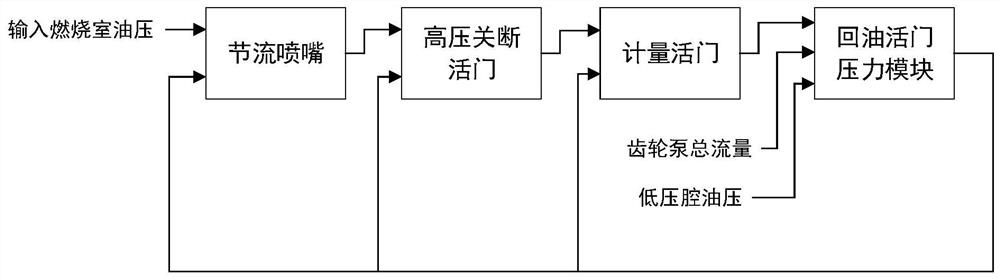

[0062] S2. According to the flow equation, the main fuel oil circuit of the mechanical hydraulic device, that is, the oil circuit that is output by the gear pump, passes through the metering valve, the high-pressure shut-off valve, and the throttle nozzle, and flows to the fuel distributor, is modeled according to the idea of pressure inversion ;

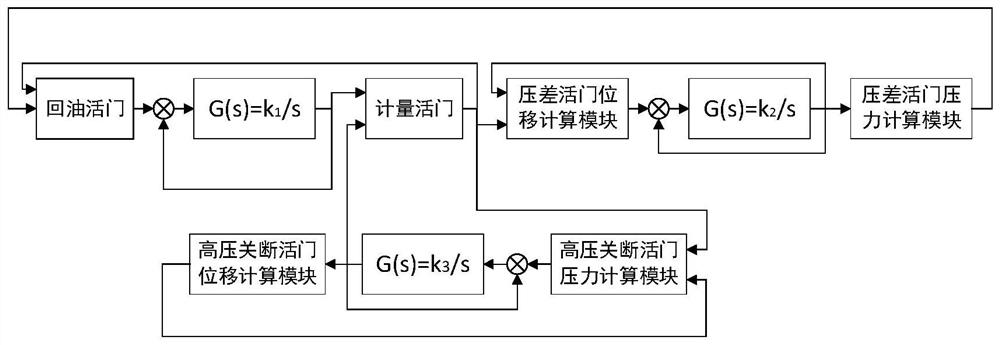

[0063] S3. After completing the modeling of the main differential pressure control circuit and the main oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com