Method for manufacturing panda type polarization-preserving fiber

A polarization-maintaining optical fiber and manufacturing method technology, applied in manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of low drawing speed, difficult to reach optical fiber, easy optical fiber jitter, etc., and achieve the improvement of stress distribution consistency, The effect of reduced lateral fluctuations and optimized mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

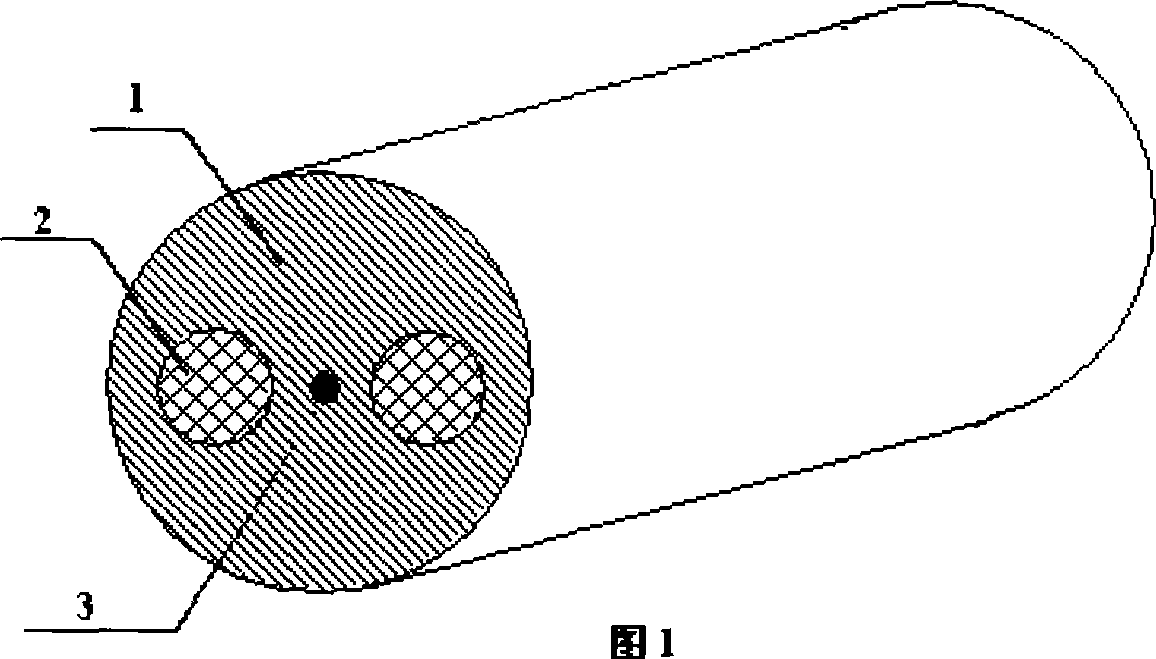

[0041] Panda-type polarization-maintaining fiber includes a cladding 1, a circular stress zone 2 and a fiber core 3, which are respectively polarization-maintaining fiber, wherein the circular stress zone is formed by the stress rod in the combined optical fiber preform during the drawing process, and the fiber core is formed by The core rod in the combined optical fiber preform is formed during the drawing process.

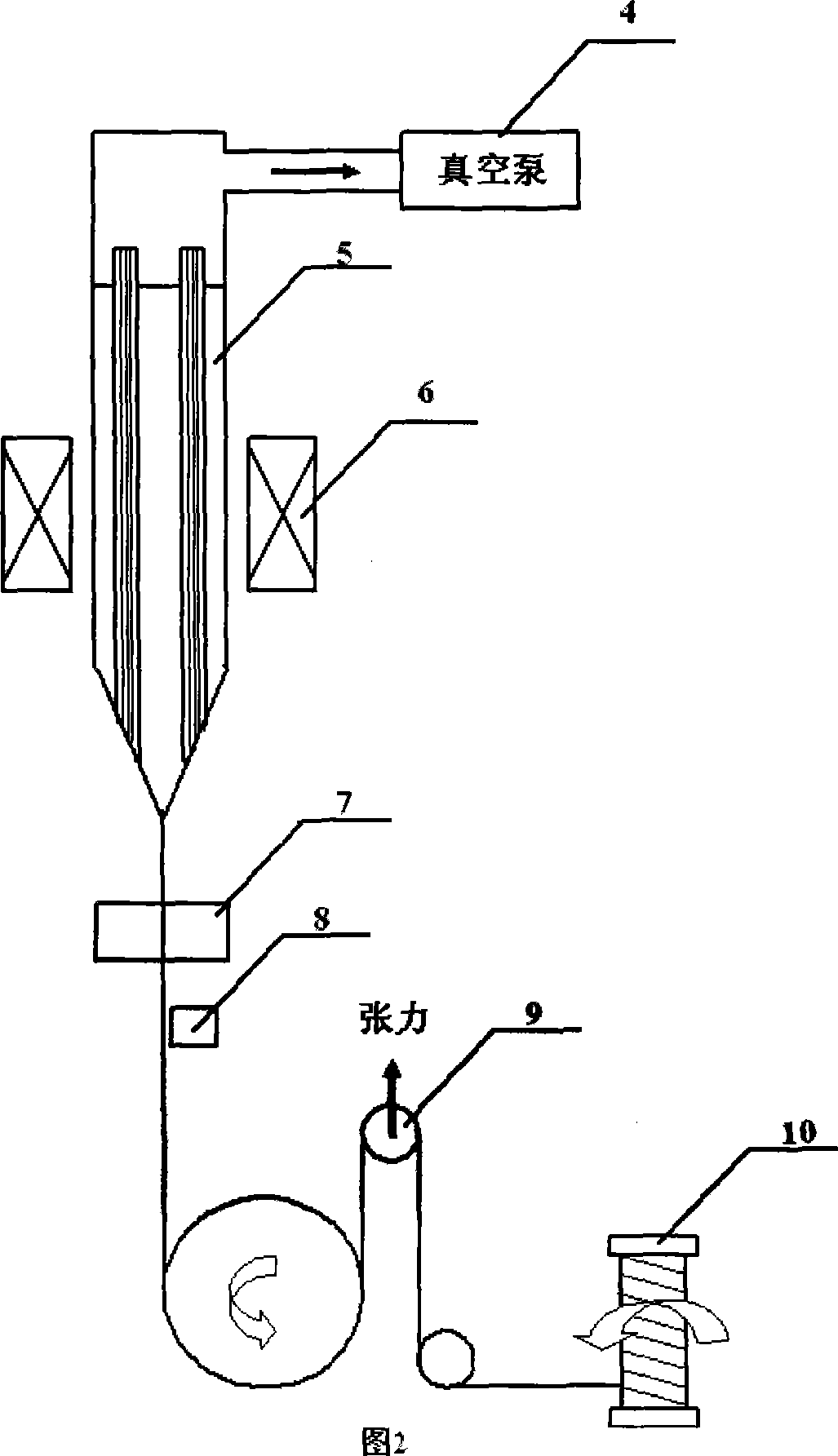

[0042] Fig. 2 is a schematic diagram of the drawing process of panda-type polarization-maintaining optical fiber. Wherein the combined optical fiber preform 5 is placed in the wire drawing furnace 6, the upper end of the combined optical fiber preform is connected to the vacuum pump 4, the temperature of the wire drawing furnace 6 can reach 2000 degrees Celsius, and the vacuum pump 4 can keep the vacuum between the stress rod and the hole u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com