Process and apparatus for removing foreign matter such as 'butyl mercaptan' from 'terbufos' crude product liquid

A technology of tertiary thiol and tertiary phosphonium, which is applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of foreign exchange consumption, and achieve low equipment investment, easy adjustment, and convenient start and stop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

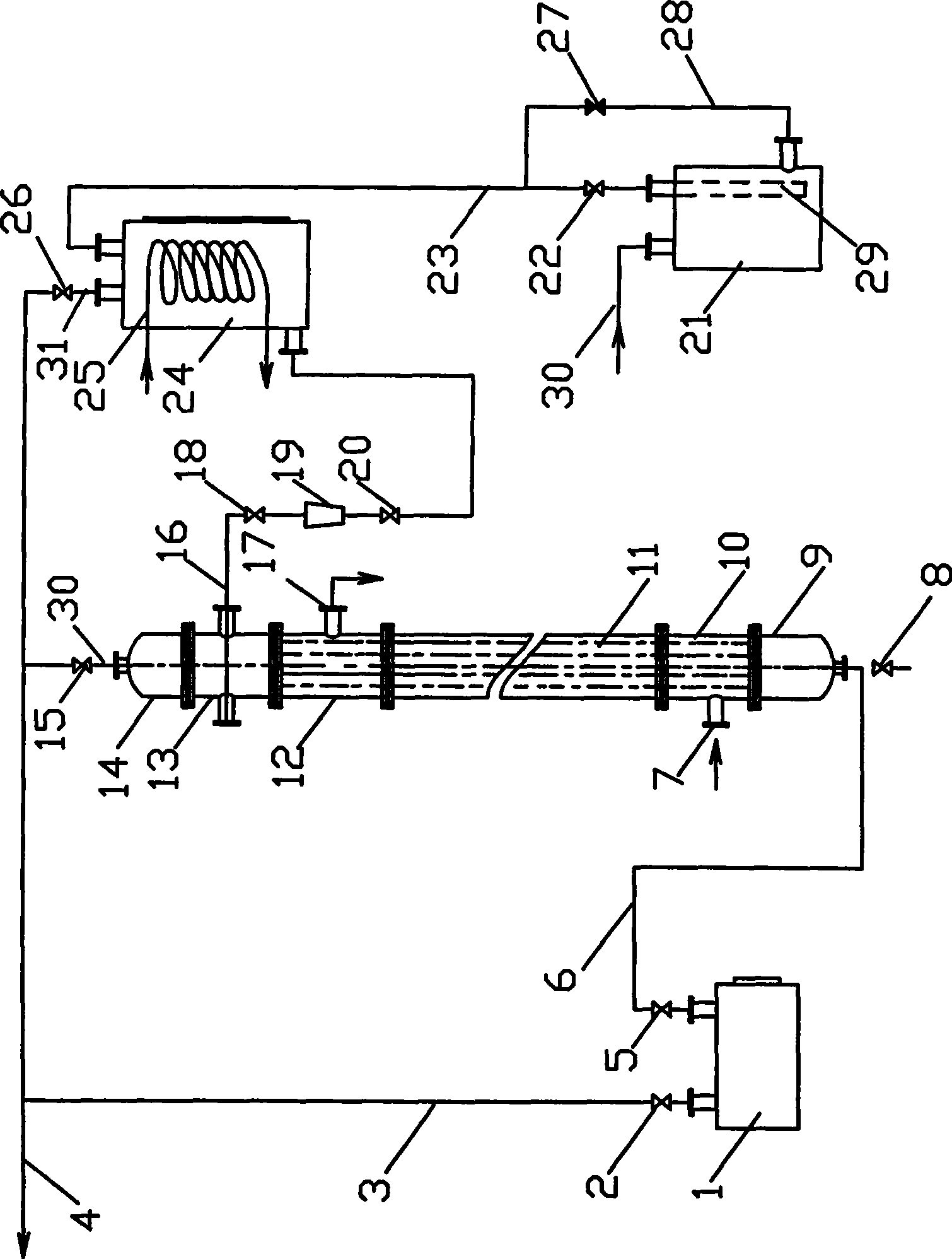

[0018] A process for removing impurities such as "tert-butyl mercaptan" from "tert-butylphosphine" crude product liquid, the process steps are: 1) put phosphorus pentoxide, absolute ethanol, formaldehyde and ter-butyl mercaptan in the reaction tank in two steps The crude product liquid of "terbuylphosphine" obtained after condensation reaction and liquid separation treatment is stored in the raw material tank 21 through the delivery pipe 30, ②open the riser valve 22, open the vacuum device connected with the main vacuum pipe 4, and open the high-level tank negative Pressure valve 26, the "terbutylphosphine" crude product liquid filtered by the filter screen 29 will be transported to the high position tank 24 through the riser 23, ③ simultaneously open the negative pressure valve 15 of the vertical falling film distillation tower and the negative pressure valve 2 of the finished product tank to make The whole system is in a negative pressure state. ④ Pass high-temperature steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com