PVDC copolymerization emulsion, preparation and uses thereof

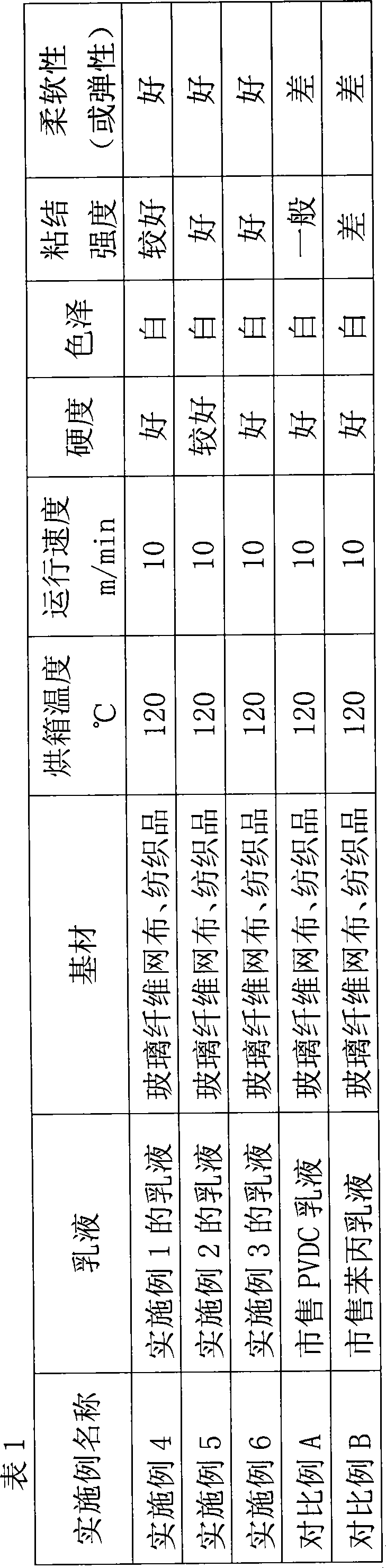

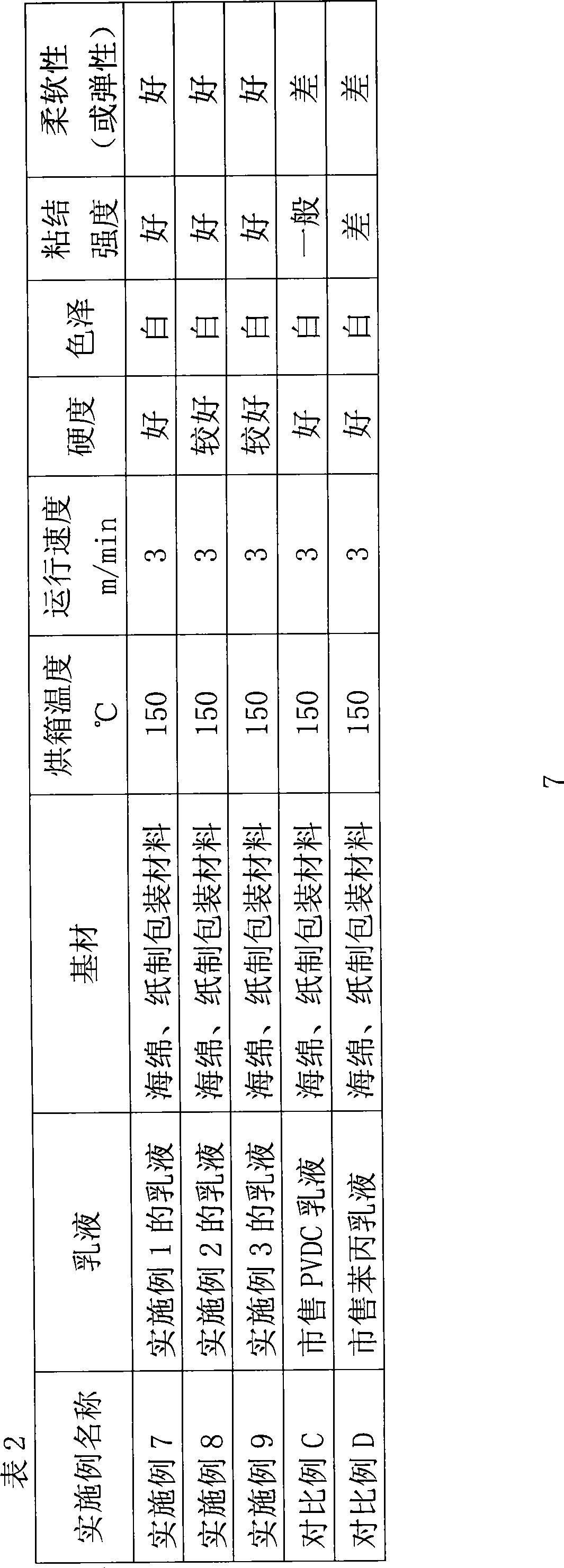

A technology of copolymerized emulsion and butyl acrylate, used in textiles and papermaking, coatings, paper coatings, etc., can solve the problems of discoloration of PVDC emulsion, inability to meet the use, and the coating film is not soft, and achieves strong adhesion, good elasticity, white color effect

Active Publication Date: 2010-08-25

ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN101186666A discloses a method for preparing polyvinylidene chloride and acrylate copolymer latex, which mainly solves the discoloration problem of PVDC emulsion; CN1986583A discloses a special water-based PVDC latex for coating on special cloth and its preparation method. The content of vinylidene chloride and the content of unsaturated fatty acid monomers are reduced to improve the water resistance of PVDC emulsion; but the above-mentioned emulsion coating film has the problems of poor setting ability (poor adhesion) and insufficient softness of the coating film, which cannot meet its in-use requirements. Use on glass fiber mesh, sponge, paper packaging materials, textiles coated by dipping process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides PVDC copolymer emulsion. The copolymer emulsion is formed by mixture monomers and accessory ingredients through copolymerizing. The mixture monomer contains 65 percent to 82 percent of vinylidene chloride, 15 percent to 35 percent of unsaturated fatty acid ester monomer, 3 percent to 8 percent of unsaturated fatty acid and 0.001 percent to 2 percent of perfluoro-unsaturatedfatty acid C3 to C6 ester monomer. The copolymer emulsion also contains the three-layer structural particles, the core-shell particles of which are all VDC / MMA / BA: the core layer is 20 percent to 84 percent of VDC and 16 percent and 80 percent of comonomer; the middle layer is 80 percent of VDC and 18 percent and 20 percent of comonomer; the outmost layer is 30 percent to 80 percent of VDC, 20 percent and 60 percent of comonomer and trace amount of C3 to C6 perfluoroester. The ratio of each layer is 5 to 30:25 to 70:15 to 30. The invention also provides a preparation method of the copolymer emulsion and an application of the copolymer emulsion in fields of fiberglass mesh fabrics, sponges, paper packaging materials, textiles and the like which use impregnating technical coating.

Description

technical field The invention relates to PVDC copolymer emulsion, its preparation method and its application in the fields of glass fiber mesh cloth, sponge, paper packaging material, textiles and the like coated by dipping process. Background technique In recent years, glass fiber mesh impregnated with styrene-acrylic emulsion has been widely used in energy-saving buildings. It will lose its due strength and fixing effect) and its high cost has limited its application. The main component of polyvinylidene chloride (PVDC) is vinylidene chloride (VDC), which is characterized by crystallinity, so it has high barrier function after film formation, but PVDC homopolymer has poor conjunctival properties, is not soft, and cannot Use: Coating performance and film performance are usually improved by copolymerization, and the higher the VDC component, the easier to crystallize, good barrier performance, and good water resistance, but the higher the film hardness, the worse its cryst...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F214/08C08F2/24C09D127/08D06M15/263D21H19/22C08F220/10C08F220/06

Inventor 陈繁荣韩金铭舒文晓苏兰辉吴宇鹏史红亮

Owner ZHEJIANG QUZHOU JUSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com